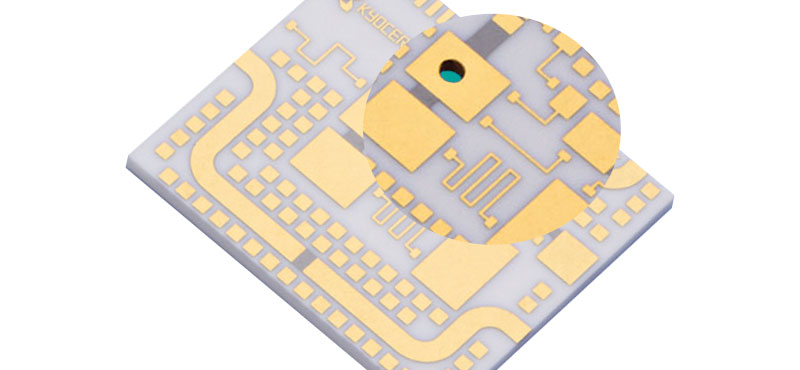

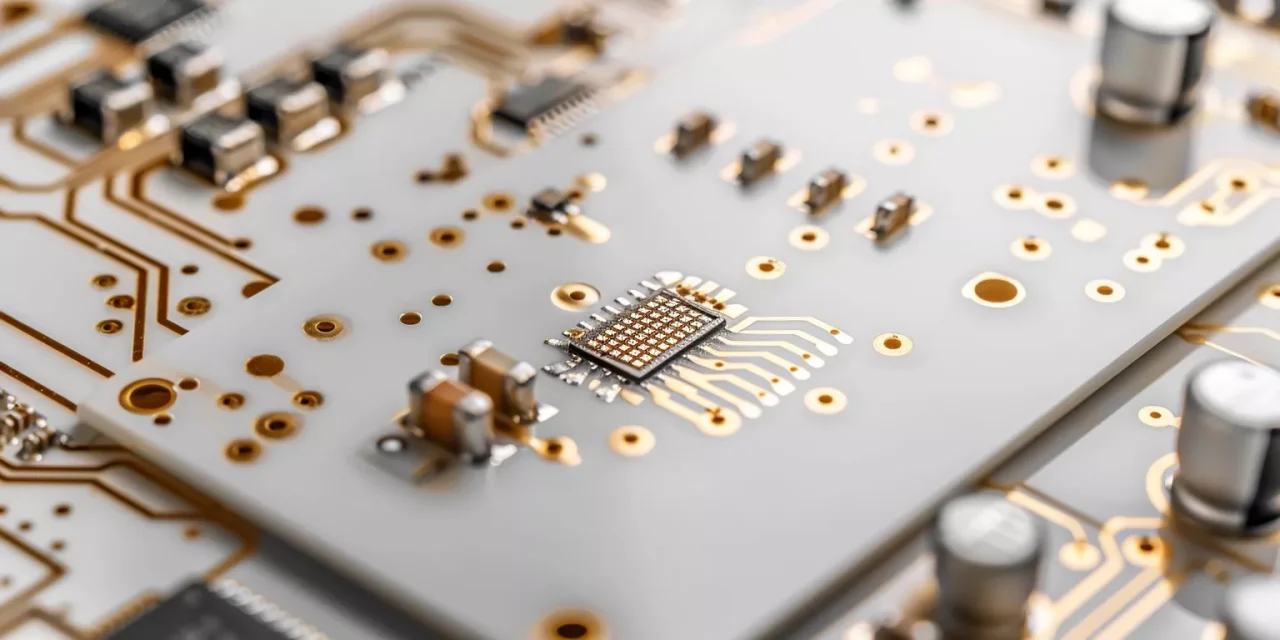

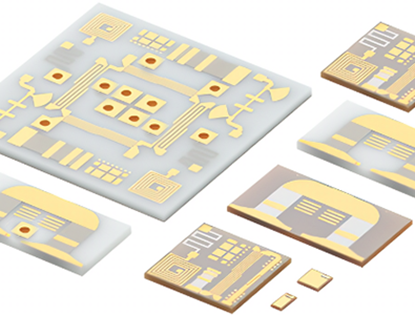

What Is a Ceramic PCB? A Ceramic PCB is a high-performance printed circuit board manufactured using ceramic substrate materials such as Alumina (Al₂O₃), Aluminum Nitride (AlN), or Beryllium Oxide (BeO). Unlike traditional FR-4 PCBs, Ceramic PCBs provide: Excellent thermal conductivity High mechanical strength Superior electrical insulation Stable performance in extreme environments Ceramic PCB technology is...

HomeTag

Alumina PCB - KKPCB

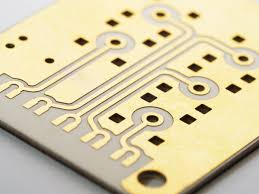

What Is an Alumina PCB? An Alumina PCB is a type of ceramic PCB manufactured using aluminum oxide (Al₂O₃) as the base substrate. Unlike traditional FR-4 materials, Alumina PCB provides superior thermal conductivity, excellent electrical insulation, and outstanding stability under high temperature and high power conditions. Because of these characteristics, Alumina PCBs are widely used...

What Is an Alumina PCB? An Alumina PCB is a ceramic printed circuit board fabricated using aluminum oxide (Al₂O₃) as the substrate material. Compared with organic laminates, Alumina PCBs provide superior thermal conductivity, excellent electrical insulation, and outstanding resistance to high temperature and harsh environments. Alumina PCBs are widely used in power electronics, semiconductor packaging,...

What Is Alumina PCB? An Alumina PCB is a ceramic printed circuit board fabricated using aluminum oxide (Al₂O₃) as the substrate material. Alumina ceramic PCBs are widely used in high-power, high-temperature, and high-reliability electronic applications due to their excellent thermal conductivity, electrical insulation, and mechanical strength. Compared with traditional FR-4 PCBs, Alumina PCBs provide superior...

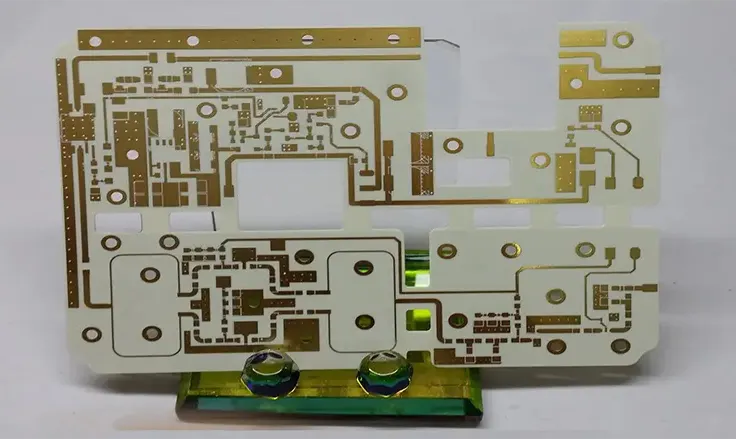

Ceramic PCB: The Ideal Solution for Heat Dissipation and High-Reliability Electronics As electronic products become smaller, more powerful, and more integrated, thermal management has become one of the biggest challenges in modern PCB design. In applications such as power modules, high-brightness LEDs, automotive electronics, and industrial control systems, standard FR4 boards may struggle with heat...

As modern electronics move toward higher power density, smaller form factors, and more demanding operating environments, thermal performance has become one of the most critical design factors. In applications such as power modules, LED lighting, automotive electronics, industrial power control, and advanced SiC/GaN power devices, conventional FR-4 PCBs may struggle with heat dissipation, long-term reliability,...

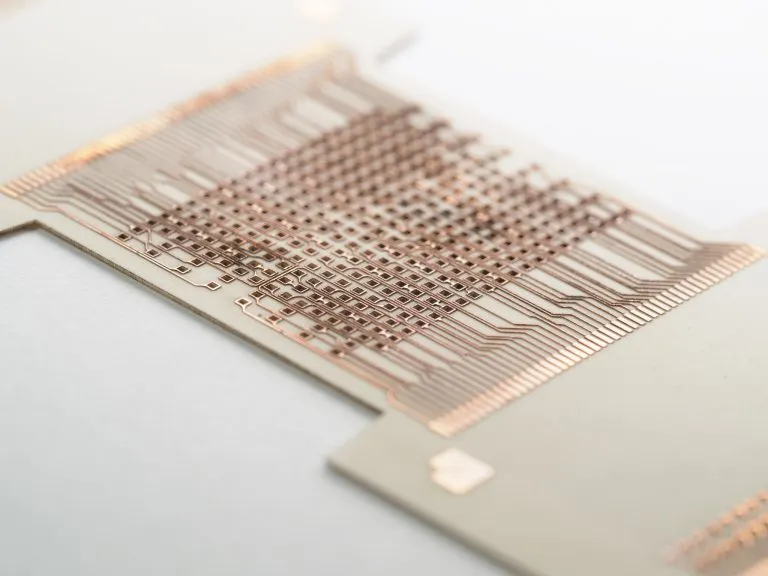

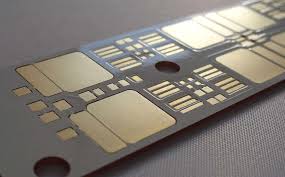

Alumina PCB substrates have become a cornerstone technology for next-generation power electronics, especially in systems where thermal conductivity, electrical insulation strength, and long-term environmental stability directly define system reliability. As power densities continue to rise in EV inverters, industrial motor drives, renewable-energy converters, and high-voltage power supplies, engineers are increasingly replacing traditional FR-4 and metal-core...

Al₂O₃ PCB platforms have become a critical foundation for next-generation automotive control units, particularly in systems where high thermal load, vibration resistance, and electrical stability determine long-term reliability. As automotive architectures evolve toward high-power ADAS sensors, electric powertrain modules, and high-density ECU clusters, alumina PCB substrates provide the mechanical strength and heat dissipation efficiency required...

High-power LED systems require extreme reliability, efficient heat spreading, and stable electrical performance across thousands of thermal cycles. Alumina PCB, Alumina Ceramic PCB, and Al₂O₃ PCB substrates have become the preferred materials for LED lighting modules due to their high thermal conductivity, mechanical stability, and superior dielectric strength. 1. Heat Dissipation for High-Power LED Packages...

Introduction to Aluminum Oxide (Al₂O₃) Ceramic PCBs In the field of printed circuit board (PCB) manufacturing, the choice of substrate material plays an essential role in determining the product’s performance, reliability, and heat dissipation capability. Ceramic PCBs—particularly those using Aluminum Oxide (Al₂O₃)—have become increasingly popular due to their outstanding thermal and electrical properties. This article...