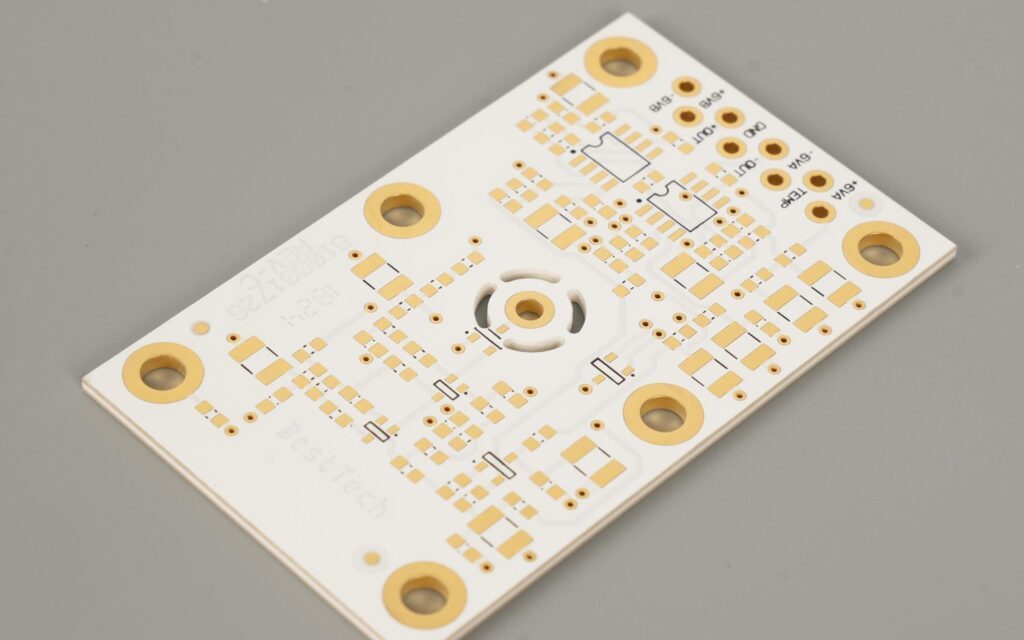

A Ceramic PCB is a substrate technology selected when thermal limits, electrical insulation, and mechanical stability become primary system constraints. In high-power and high-voltage electronic systems, ceramic substrates are not simply alternatives to organic laminates—they function as integrated thermal and structural elements within the overall design architecture. Ceramic PCB as a Thermal Path Element In...

HomeCategory

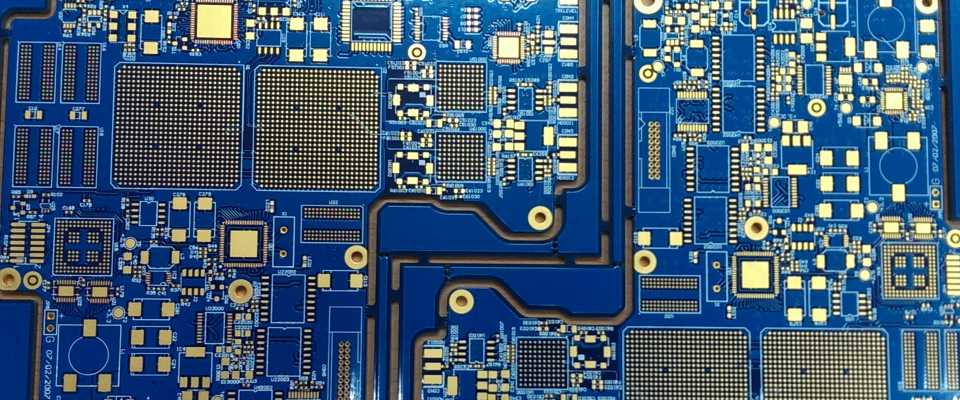

PCB Materials | FR-4, High-Frequency, Low-Loss & Heavy Copper - KKPCB

In high-frequency electronic systems, a PTFE PCB is not selected to improve margins—it is selected because the loss budget leaves no alternative. When signal fidelity, phase coherence, and predictable impedance directly affect system functionality, PTFE-based laminates become a system-level engineering decision rather than a material upgrade. Why PTFE PCB Is Chosen at the Architecture Level...

Taconic PCB materials are widely recognized in high-frequency and microwave PCB applications for their low dielectric loss, stable dielectric constant (Dk), and high thermal reliability. As RF and high-speed digital systems continue to demand higher bandwidths and tighter signal integrity, Taconic laminates provide a proven solution for minimizing insertion loss and maintaining performance consistency. Material...

Engineering TechnologiesElectronics Industry NewsPCB Assembly (PCBA)PCB DesignPCB ManufacturingPCB Materials

Selecting an ATE PCB Supplier for High-Performance Automated Test Equipment Applications

An ATE PCB (Automated Test Equipment PCB) is a specialized circuit board designed to interface with test instrumentation for semiconductor devices, modules, and high-speed systems. A reliable ATE PCB supplier plays a critical role in ensuring signal integrity, mechanical precision, and long-term reliability in high-volume testing environments. Importance of High-Quality ATE PCBs ATE PCBs must...

Hybrid PCB materials are engineered substrates that combine multiple material types to achieve optimized electrical, thermal, and mechanical performance in demanding electronic applications. By integrating properties of FR-4, high-frequency laminates, PTFE, or ceramic materials, hybrid PCBs enable designers to meet multi-domain requirements that a single material cannot satisfy. Material Characteristics of Hybrid PCB Materials The...

High TG materials are essential in modern PCB design where thermal performance, dimensional stability, and long-term reliability are critical. TG, or glass transition temperature, defines the point at which PCB substrates transition from a rigid to a more flexible state. Materials with high TG are engineered to maintain mechanical integrity, electrical performance, and impedance stability...

Low loss materials play a foundational role in modern PCB design where high-frequency, high-speed, and high-data-rate signals define system performance limits. As signal frequencies extend into multi-gigahertz and mmWave ranges, dielectric loss becomes a dominant factor affecting insertion loss, phase stability, and overall signal integrity. Selecting appropriate low loss materials is therefore a critical engineering...

High Frequency Laminates are specialized PCB substrates engineered to deliver low dielectric loss, stable dielectric constant (Dk), and superior signal integrity in RF, microwave, and high-speed digital applications. Unlike conventional FR-4 materials, high frequency laminates maintain predictable electrical behavior across GHz and mmWave frequencies, enabling advanced communication, radar, and aerospace systems. Material Characteristics High frequency...

A BT Epoxy PCB is a specialized organic substrate widely used in IC packaging, semiconductor interposers, and high-density electronic modules. BT (Bismaleimide Triazine) epoxy resin materials are engineered to provide enhanced thermal stability, low moisture absorption, and excellent dimensional control, making BT Epoxy PCBs a preferred choice for fine-pitch and high-I/O-count packaging environments. Unlike standard...

An Aluminum Nitride PCB (AlN PCB) is a ceramic-based circuit substrate engineered for electronic systems that demand exceptional thermal conductivity, electrical insulation, and dimensional stability under high power density and elevated temperature conditions. In power electronics and high-reliability applications, material selection is not a secondary decision—it defines system performance limits. Material-driven Aluminum Nitride PCB design...