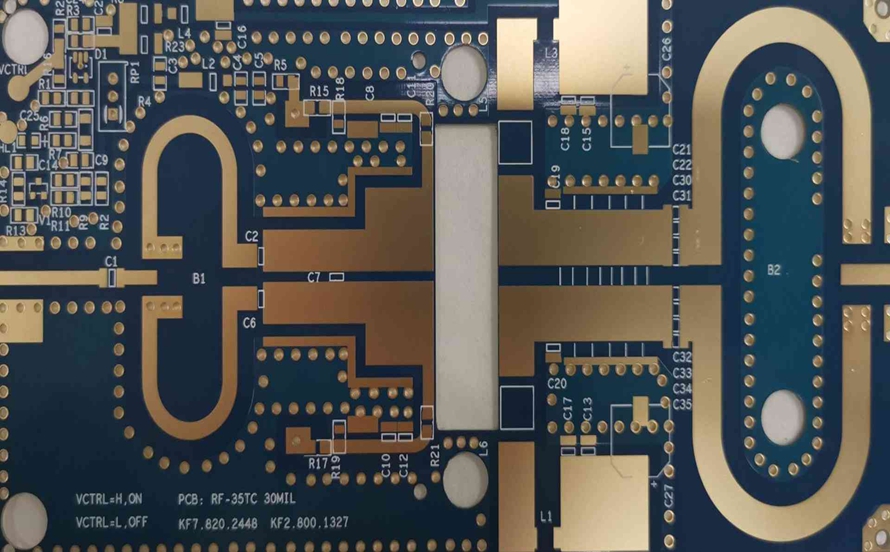

RF-35 PCB laminates operate in a class where dielectric precision directly shapes RF linearity, bandwidth uniformity, and system-level efficiency. Modern wireless products—Wi-Fi 6/7 modules, IoT gateways, sub-6 GHz links, and microwave-band transceivers—depend on stable Dk/Df behavior to maintain predictable impedance and low insertion loss. RF-35 offers a low-loss dielectric platform designed for controlled RF propagation,...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

1. Why Aerospace RF Boards Are Entering the RO4835 Era in 2025 In aerospace navigation and telemetry links (L/S/C/Ku/Ka bands), temperature swings from –55°C on the ground to +125°C in high-altitude low-pressure environments are routine. Traditional high-frequency materials such as RO4350B or common PTFE either suffer excessive Dk drift or catastrophic oxidation of the “LoPro”...

Laptop Wi-Fi 6/7 systems operate with extremely tight RF tolerances: multi-band OFDMA, 4096-QAM, and Multi-Link Operation demand predictable impedance, low-loss transmission, and strict phase alignment. Traditional FR-4 substrates introduce thermal drift, inconsistent Dk, and elevated loss, making them insufficient for 6 GHz high-band routing. RO4350B PCBs solve these issues by combining ceramic-filled hydrocarbon dielectric stability...

RO4350B PCB materials are widely deployed in 5G smartphone RF front-end modules because they provide a balanced dielectric profile, low-loss characteristics, and stable RF transmission up to sub-6 GHz and selected mmWave bands. Modern antenna arrays, PA/LPF modules, LNA chains, and tunable impedance networks face stringent constraints in signal integrity, power density, EMI coupling, and...

Megtron 7 PCB laminates are widely adopted in 5G servers, AI computing accelerators, and cloud networking equipment due to their exceptionally low dielectric loss and superior stability at 28–112 Gbps PAM4 and mmWave bands. As system architectures transition toward high-density multi-lane SerDes and advanced RF interconnects, PCB materials become a primary constraint influencing channel loss...

SiC PCB for High-Power Modules and Automotive Powertrain Systems SiC (Silicon Carbide) devices are reshaping high-power electronics. Their wide-bandgap characteristics—high breakdown voltage, fast switching, and elevated junction temperatures—push PCB substrates into thermal, electrical, and mechanical stress profiles that exceed the range of traditional FR-4 and generic high-Tg laminates.A SiC PCB supporting traction inverters, onboard chargers,...

High-frequency Wi-Fi 6/7 antenna modules in modern laptops demand PCBs that maintain low insertion loss, precise phase alignment, and robust EMI suppression within compact layouts. TLY-5 PCB laminates, with a dielectric constant of 3.45 ± 0.03 and dissipation factor of 0.0012 @10 GHz, provide low-loss RF transmission and dimensional stability essential for multi-band performance. KKPCB...

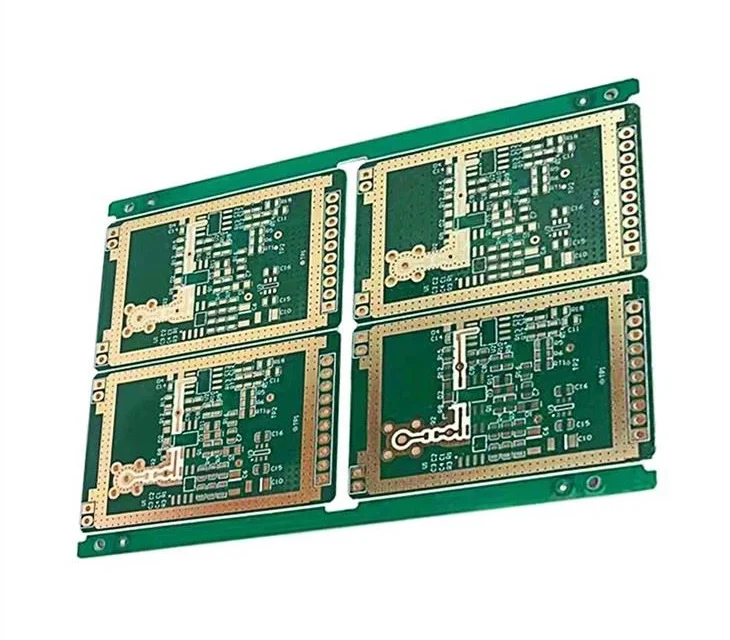

Heavy Copper PCBs: High-Current Solutions for Power Electronics As electronic systems evolve toward higher power density, stronger reliability requirements, and increasingly harsh operating environments, Heavy Copper PCBs have become indispensable across power electronics, automotive systems, industrial control, and energy infrastructure. Unlike standard PCBs—typically manufactured with 1oz–3oz copper—a Heavy Copper PCB is defined as any PCB...

PCB MaterialsCustomer CaseElectronics Industry NewsEngineering TechnologiesPCB DesignPCB Manufacturing

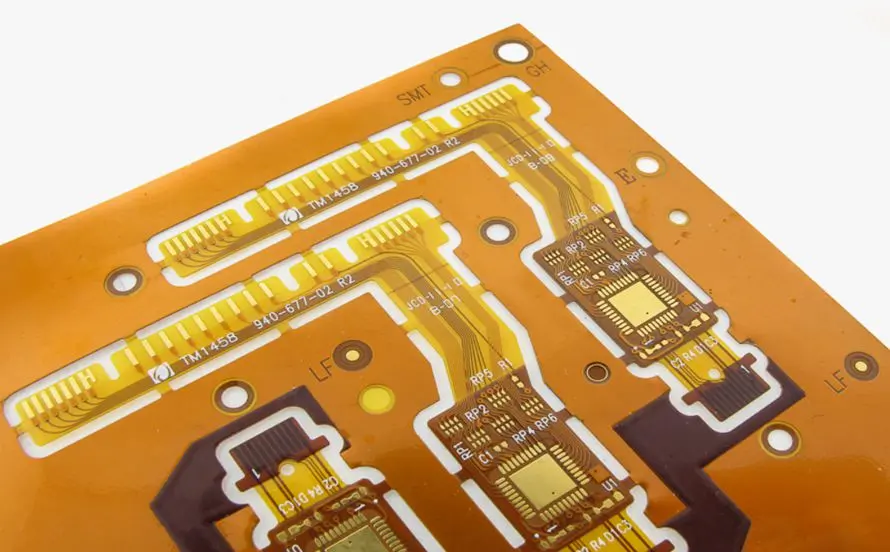

Rigid-Flex PCBs: Engineering Benefits, Key Challenges, and Advanced Manufacturing Insights from KKPCB

Rigid-Flex PCBs: Advantages, Challenges, and Engineering Insights from KKPCB As electronic systems shrink in size and grow in capability, the demand for PCB technologies that combine reliability, flexibility, and mechanical resilience continues to rise. From aerospace and defense to medical devices, consumer electronics, and industrial automation, modern products increasingly require circuits that survive vibration, bending,...

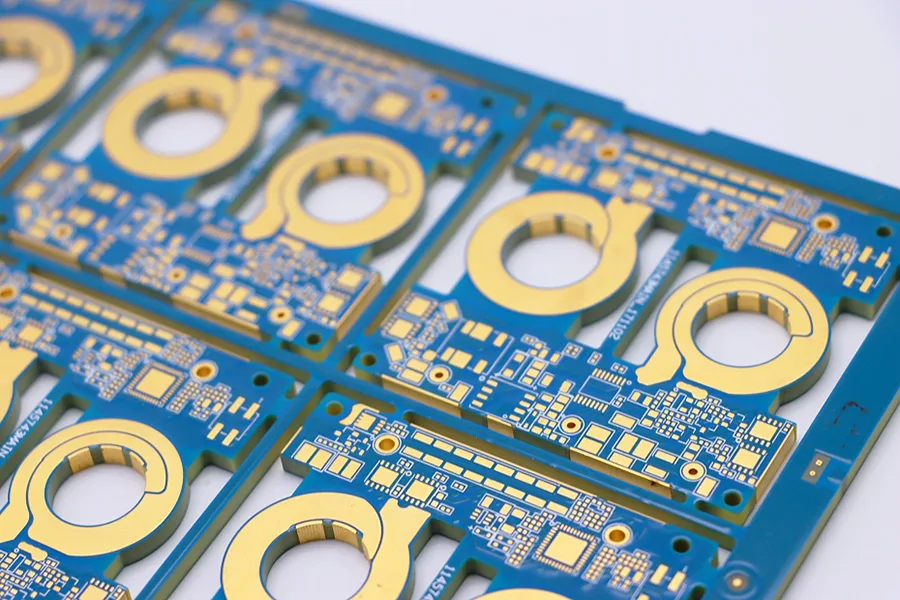

What Is a Low Loss PCB? Premium Materials, Performance Advantages & Applications In high-frequency electronics, signal integrity is everything. As data rates climb and RF systems move into the mmWave range, traditional FR-4 PCBs quickly become inadequate due to excessive dielectric loss, copper loss and thermal instability. At KKPCB, we engineer Low Loss PCBs specifically...