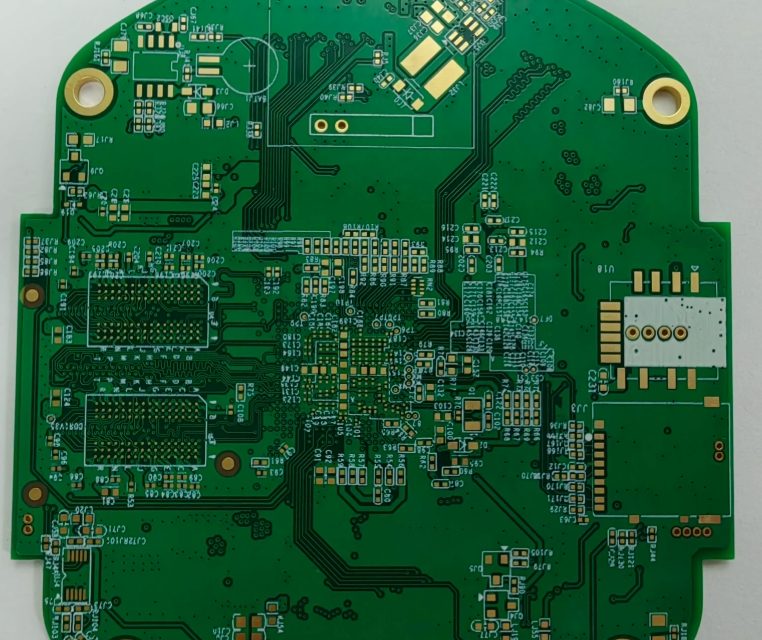

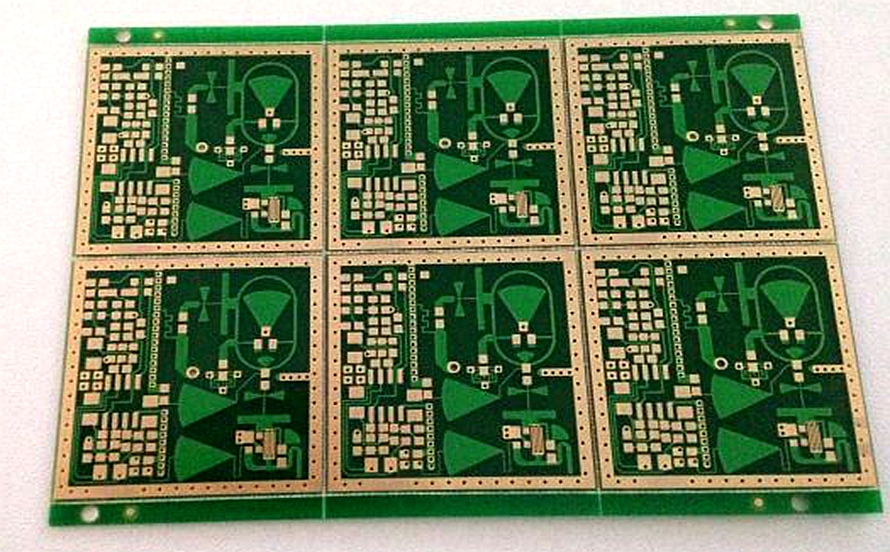

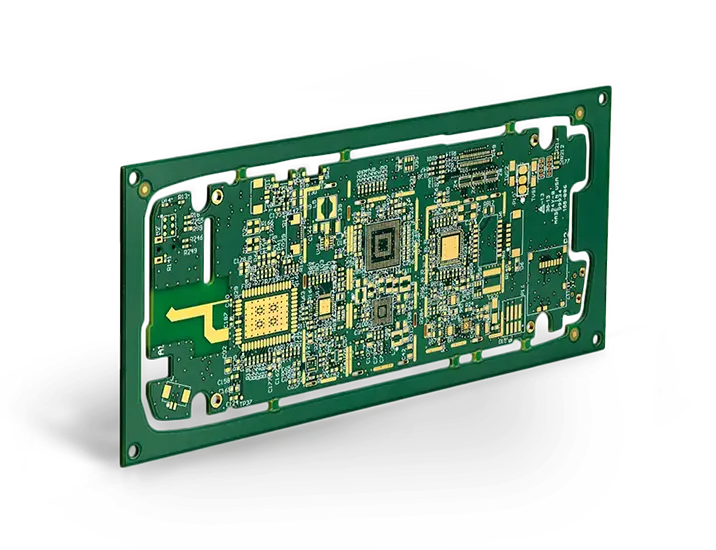

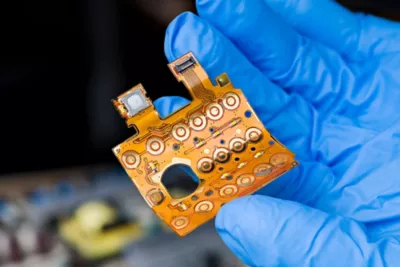

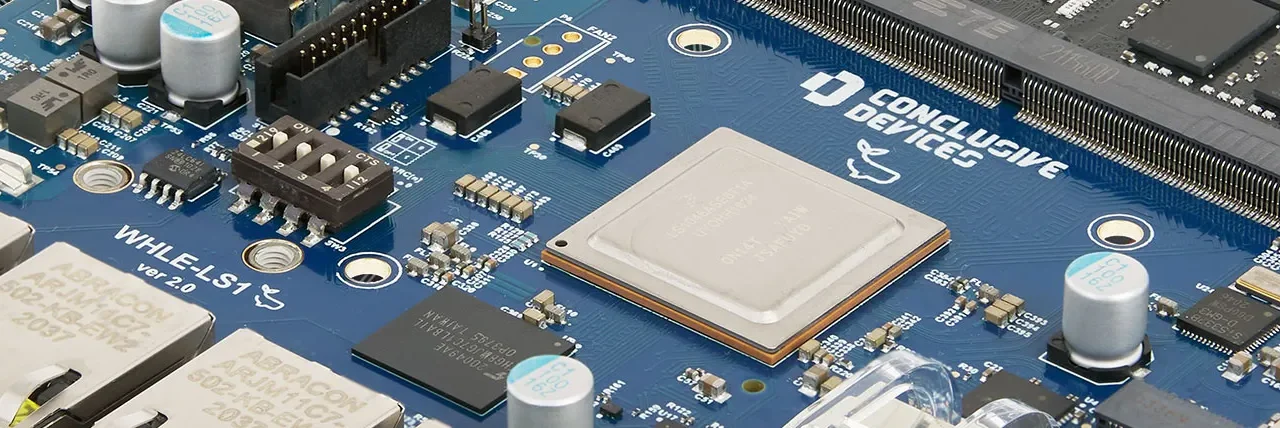

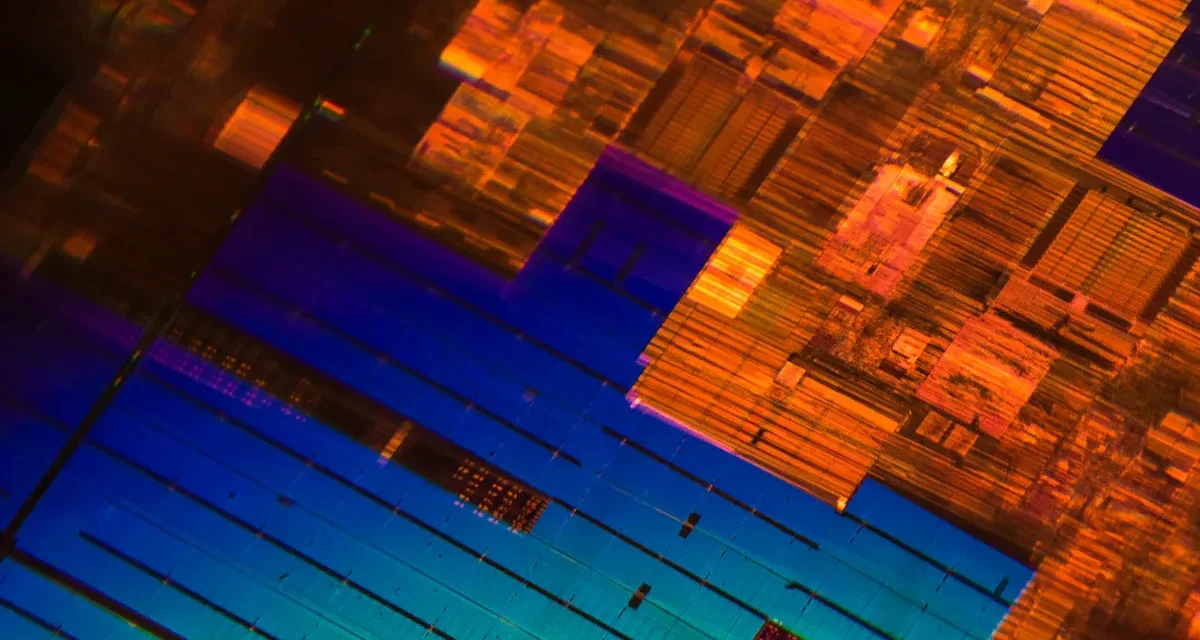

Order Microwave PCB: Precision Manufacturing for High-Frequency and Microwave Applications

Microwave circuits operate at extremely high frequencies where even minor PCB variations can significantly affect performance. When engineers and purchasing teams order microwave PCBs, precision manufacturing, low-loss materials, and strict impedance control are essential to ensure stable and reliable microwave signal transmission. This article outlines key considerations when ordering microwave PCBs and how professional manufacturers...