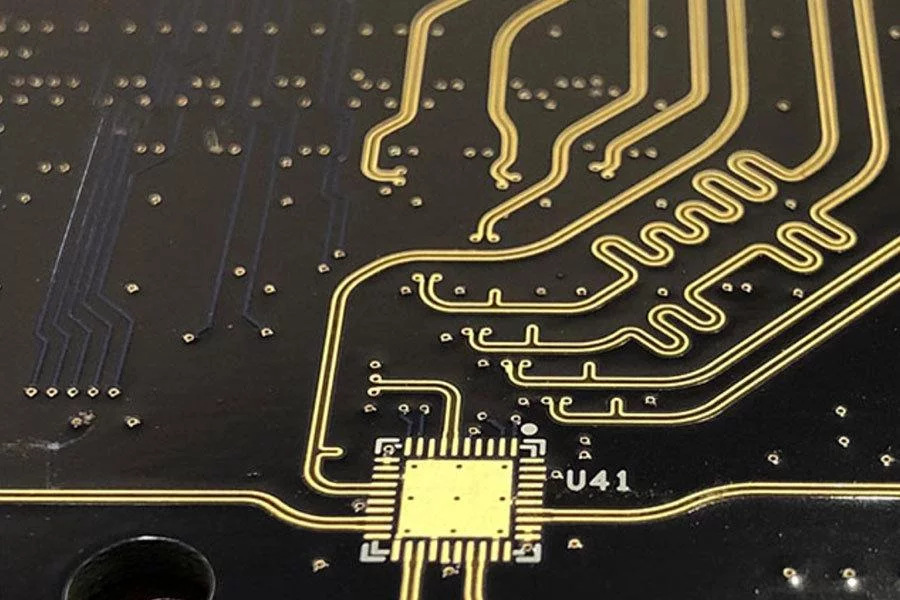

What Is a High Speed Logic PCB? A High Speed Logic PCB is a printed circuit board designed to support high-speed digital logic circuits, where signal rise times are extremely fast and timing accuracy is critical. These PCBs ensure minimal signal distortion, precise timing, and reliable data transmission for high-performance computing, telecommunication, and semiconductor testing...

HomeCategory

PCB Design Services | Professional PCB Layout & Design - KKPCB

What Is a Signal Integrity PCB? A Signal Integrity (SI) PCB is a printed circuit board designed to maintain clean, stable high-speed signal transmission across digital, analog, or mixed-signal circuits. SI PCBs are essential for applications where data integrity, minimal signal distortion, and timing accuracy are critical, such as 5G communications, high-speed computing, automotive electronics,...

What Is a High Current PCB? A High Current PCB is a printed circuit board specifically designed to carry large currents while maintaining electrical stability and thermal reliability. These PCBs are commonly used in power electronics, automotive inverters, industrial automation, renewable energy systems, and high-current semiconductor testing. High current PCBs typically feature thick copper layers,...

What Is a Microvia PCB? A Microvia PCB is a printed circuit board that uses microvias, which are very small drilled holes (typically <150 μm) to interconnect layers in high-density, multilayer HDI PCBs. Microvias enable fine-pitch routing, high pin count IC integration, and compact board layouts, making them essential for advanced electronics such as smartphones,...

What Is a High Reliability PCB? A High Reliability PCB is a printed circuit board designed and manufactured to perform consistently under extreme environmental, electrical, and mechanical conditions. These PCBs are engineered for long service life, stable electrical performance, and minimal failure risk. High reliability PCBs are essential for applications where system failure is not...

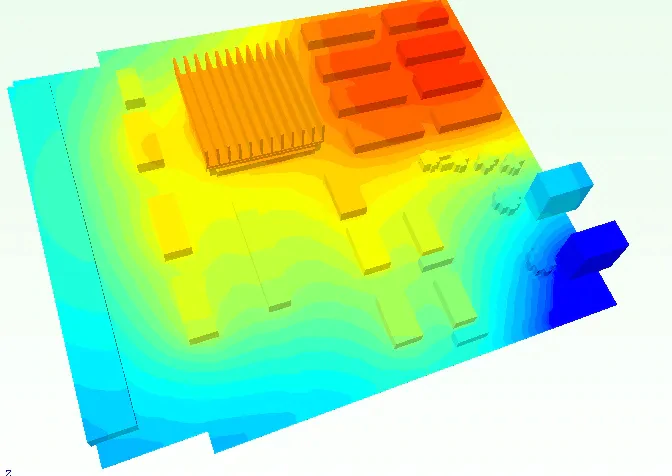

As electronic devices become more compact and powerful, effective Thermal Management PCB solutions are critical to ensure performance, reliability, and product lifespan. High-power components such as CPUs, power MOSFETs, IGBTs, LEDs, and RF amplifiers generate significant heat during operation. Without proper PCB thermal management, excessive temperature rise can lead to signal instability, reduced efficiency, and...

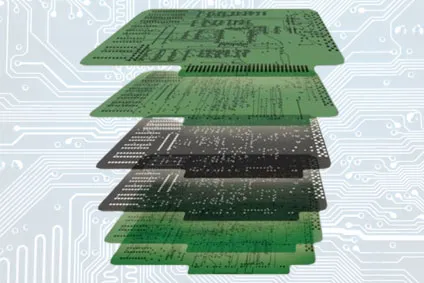

What Is a Multilayer PCB? A multilayer PCB is a printed circuit board composed of multiple copper layers separated by prepreg and core materials. Unlike single-sided or double-sided PCBs, multilayer boards provide additional routing layers, allowing engineers to design high-density circuits with improved electrical performance. Typical multilayer PCB configurations include: 4-layer PCB 6-layer PCB 8-layer...

What Is a Low Loss PCB? A Low Loss PCB is a printed circuit board designed with low dielectric loss materials to minimize signal attenuation during high-frequency and high-speed signal transmission. These PCBs are critical for applications where signal integrity, phase stability, and low insertion loss are essential. Low loss PCBs are widely used in...

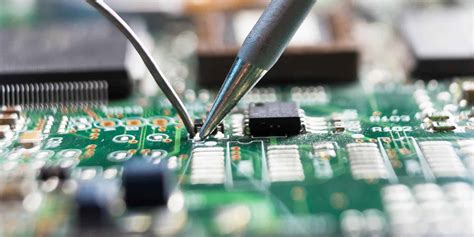

What Is a Fine Pitch PCB? A Fine Pitch PCB is a printed circuit board designed to support fine-pitch components, such as fine-pitch BGA, QFN, CSP, and high pin count ICs, where the spacing between pads and traces is extremely small. Fine pitch PCB technology is essential for modern electronics that demand high density, compact...

What Is a High Density PCB? A High Density PCB (High Density Printed Circuit Board) is designed to accommodate more components, higher pin counts, and finer routing within a limited board area. It is widely used in applications that require compact size, high performance, and complex signal routing, such as semiconductor testing, telecommunications, automotive electronics,...