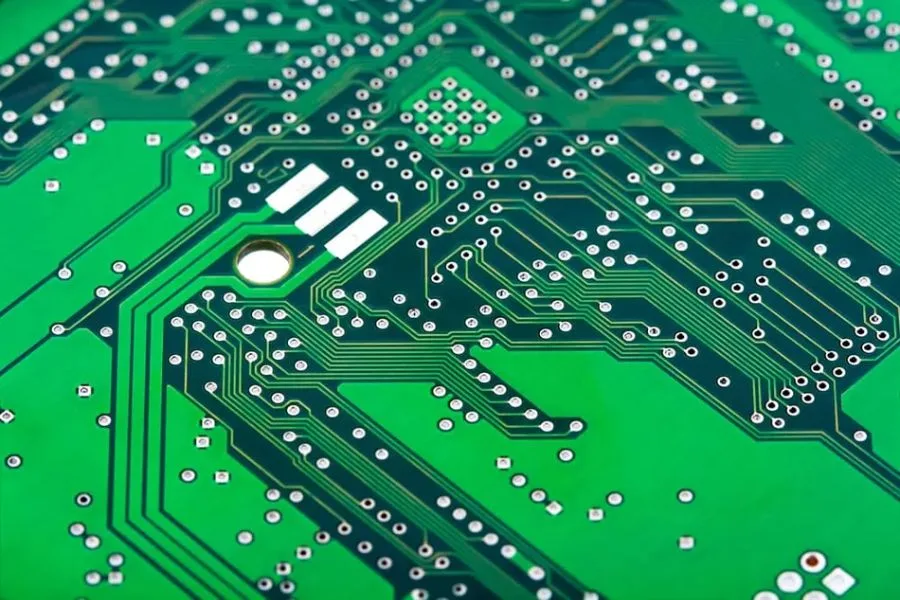

What Is a Controlled Impedance PCB? A Controlled Impedance PCB is a printed circuit board designed to maintain a specified electrical impedance value along signal traces. Controlled impedance is critical for maintaining signal quality in high-speed, high-frequency, and RF electronic systems. In modern electronic devices, high data rate signals require precise impedance matching to prevent...

HomeCategory

Advanced Engineering Technologies for PCB & PCBA Solutions - KKPCB

What Is a Buried Via PCB? A Buried Via PCB is a multilayer printed circuit board that uses vias connecting only internal layers without reaching the outer surface layers. These hidden interconnections allow designers to increase routing density while maintaining surface space for components and signal traces. Buried Via PCBs are widely used in HDI...

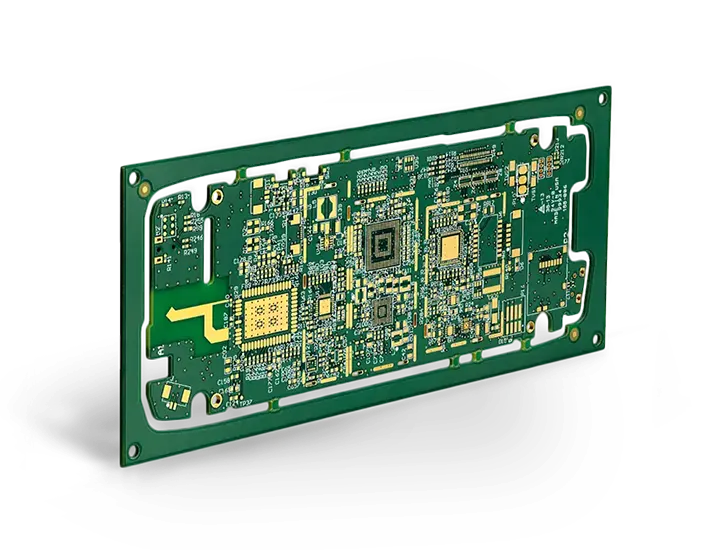

What Is a High Layer Count PCB? A High Layer Count PCB refers to a multilayer printed circuit board containing a large number of copper layers, typically 12 layers and above, designed to support highly complex circuit routing and high-speed signal transmission. High Layer Count PCBs are widely used in advanced electronic systems that require...

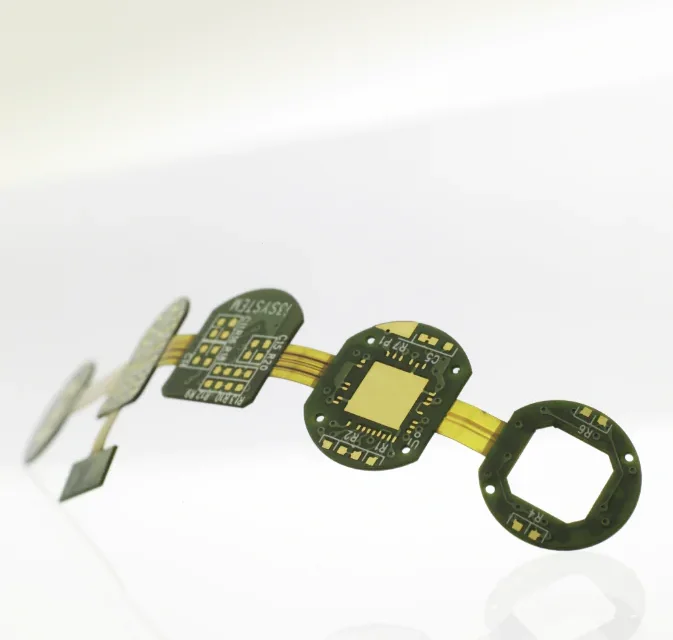

What Is a Rigid-Flex PCB? A Rigid-Flex PCB is a hybrid printed circuit board that integrates both rigid PCB sections and flexible circuit layers into a single structure. Rigid-flex PCBs allow circuits to bend or fold while maintaining the structural strength and component mounting capability of rigid boards. Rigid-Flex PCB technology reduces connector usage, improves...

What Is a Double Layer HF PCB? A Double Layer HF PCB (High Frequency PCB) is a two-layer printed circuit board specifically designed for RF and microwave signal transmission. It uses low dielectric loss materials and optimized trace layouts to maintain signal integrity at high operating frequencies. Compared with multilayer RF boards, double layer HF...

What Is a Low Dissipation Factor PCB? A Low Dissipation Factor PCB is a printed circuit board manufactured with dielectric materials that exhibit a low dissipation factor (Df), also known as loss tangent. The dissipation factor measures how much signal energy is lost as heat when electromagnetic waves propagate through the PCB substrate. Lower Df...

What Is a High TG PCB? A High TG PCB is a printed circuit board manufactured using materials with a high glass transition temperature (Tg). The Tg value indicates the temperature at which the PCB substrate transitions from a rigid state to a softer, rubber-like state. Compared to standard FR-4, High Tg PCBs maintain mechanical...

What Is a High Speed PCB? A High Speed PCB is a printed circuit board designed to support high-speed digital signals, typically operating at multi-gigabit data rates. These PCBs are essential for modern electronics where signal integrity, timing accuracy, and low noise are critical. High speed PCBs are widely used in servers, networking equipment, semiconductor...

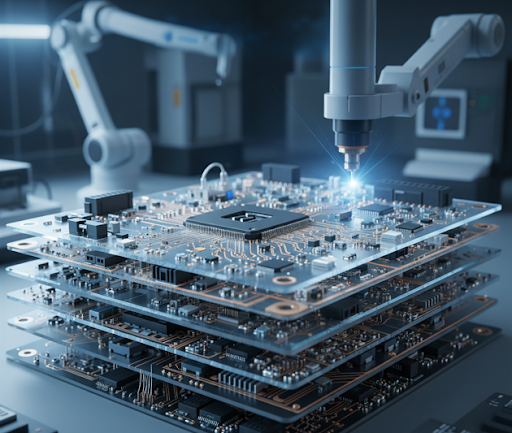

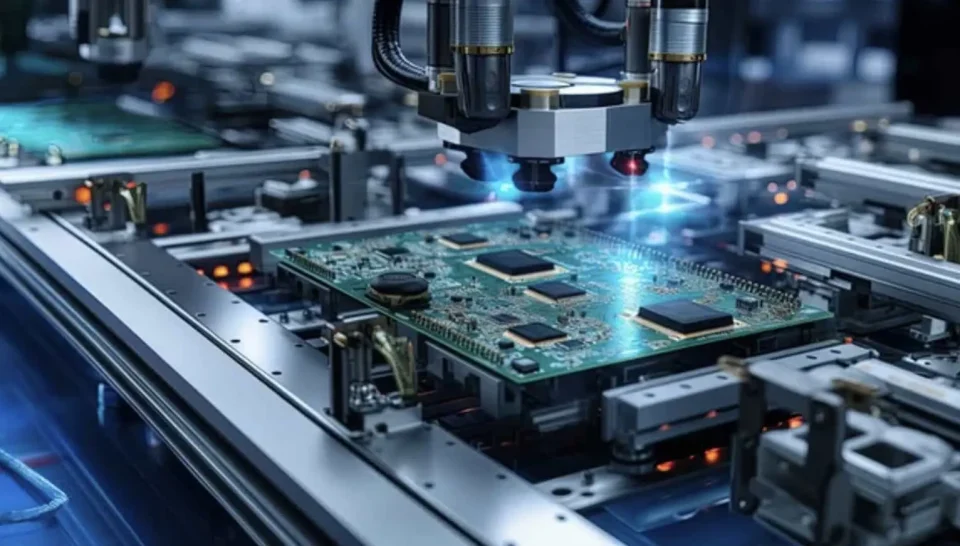

What Is an Industrial Automation PCB? An Industrial Automation PCB is a specialized printed circuit board used in factory automation, industrial control, and process automation systems. These PCBs form the core of PLC controllers, motion control units, industrial communication modules, and power control boards. Industrial automation PCBs are designed for continuous operation, harsh environments, and...

What Is a Smart Factory PCB? A Smart Factory PCB is a specialized printed circuit board used in smart manufacturing, industrial automation, and Industry 4.0 systems. These PCBs serve as the backbone of intelligent factories, enabling real-time data acquisition, automated control, machine connectivity, and predictive maintenance. Smart factory PCBs must operate reliably in harsh industrial...