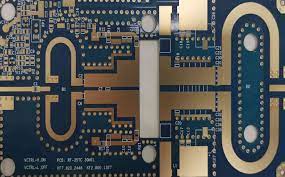

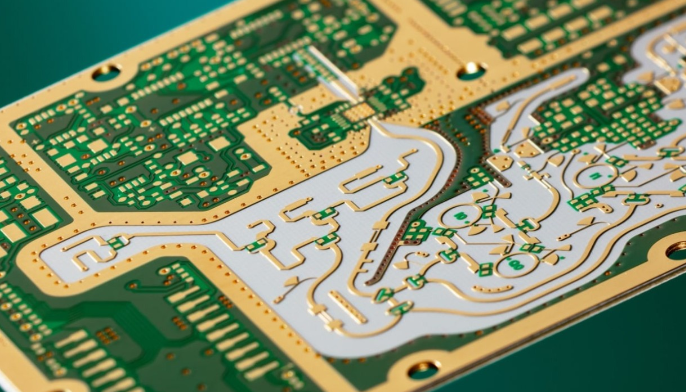

Next-generation RF transceivers—whether for 5G mmWave, SATCOM terminals, phased-array antennas, or short-range high-bandwidth links—place brutal demands on PCB materials. To maintain ultra-low insertion loss, wideband consistency, stable phase response, and clean radiation efficiency, mmWave module PCB materials must deliver precision alignment, ultra-low dielectric loss, tight Dk control, and minimal copper roughness across every layer. In...

HomeCategory

Advanced Engineering Technologies for PCB & PCBA Solutions - KKPCB

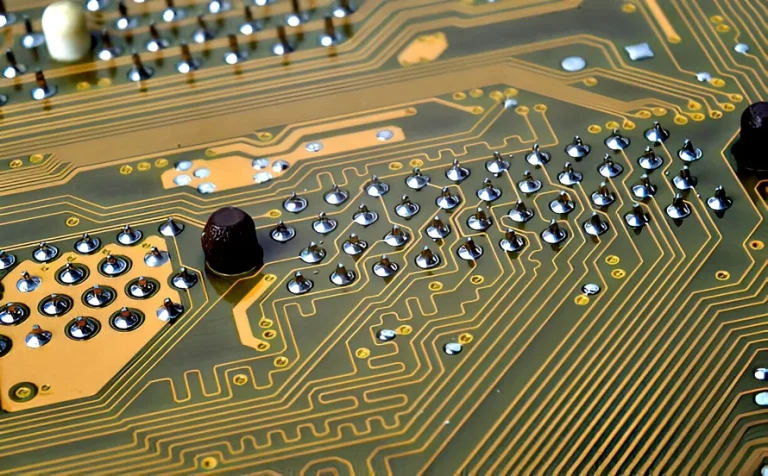

High-frequency signal integrity is the defining performance factor in modern 5G mmWave antenna systems, where routing density, insertion loss, and phase stability determine overall RF efficiency. As 5G architectures transition to 26–29 GHz, 37–40 GHz, and 60 GHz mmWave bands, the electrical behavior of the Low Loss PCB stackup becomes just as important as the...

Accurate PCB quotation is never a guessing game. For OEMs, hardware startups and EMS partners working under compressed timelines, incomplete design files often lead to delays, cost deviations and unnecessary engineering iterations. Providing a complete engineering package—Gerber, layer stack-up, material specifications and fabrication notes—enables manufacturers to evaluate your design precisely and deliver consistent, reliable pricing...

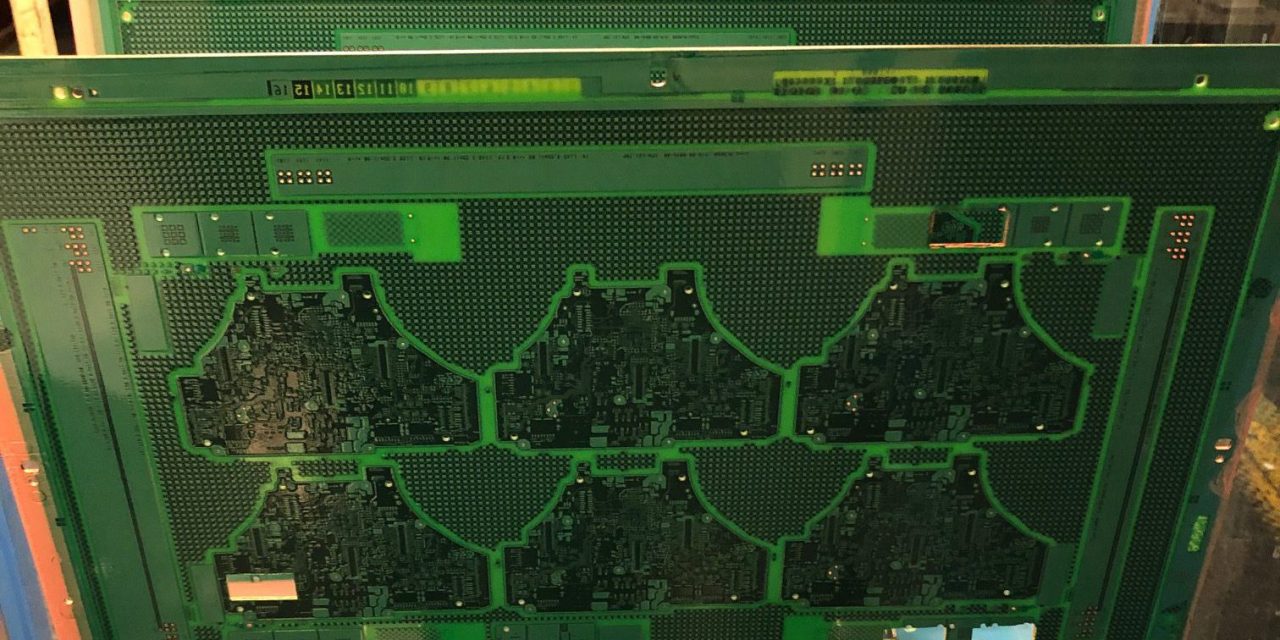

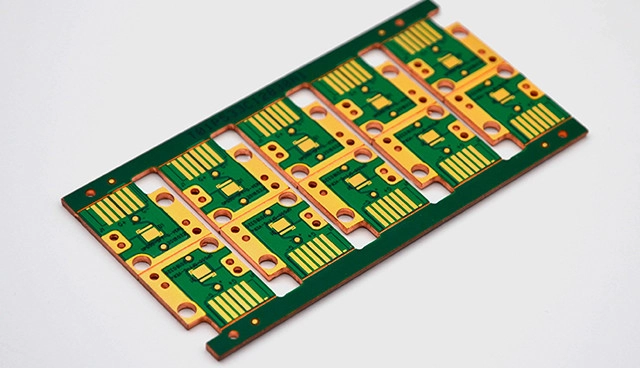

Industrial power electronics, including motor drives, UPS systems, and high-power converters, demand PCBs capable of handling high current densities while maintaining thermal stability and signal integrity. Heavy copper PCBs, typically ranging from 2 oz to 12 oz copper weight, enable efficient current flow and significantly improve heat dissipation across multilayer stackups. KKPCB specializes in multilayer...

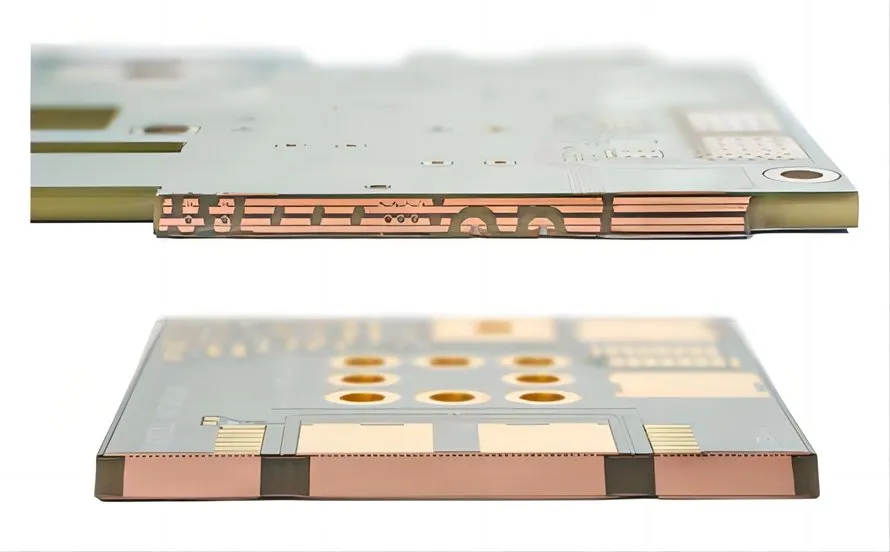

High-density RF modules used in 5G radios, SATCOM terminals, phased-array beamformers, and mmWave front-end units are increasingly constrained by thermal stress, EMI coupling, and insertion loss. As operating frequencies push beyond 10–40 GHz, traditional FR-4 structures can no longer maintain stable impedance, consistent dielectric behavior, or low-loss routing. This is where Low Loss PCB materials—such...

mmWave Module PCB Engineering for High-Frequency, Low-Loss and Thermally Stable RF Front-End Systems

The shift toward 5G FR2, advanced radar, high-resolution sensing and satellite communication has placed intense performance pressure on mmWave Module PCB design. At frequencies from 24 GHz to 86 GHz, the PCB is no longer a passive carrier—it becomes an active RF component whose materials, stackup, via transitions and routing geometries directly dictate performance. A...

In next-generation intelligent aerial surveillance platforms, UAV manufacturers face increasing demands for real-time data fusion, long-range imaging, high-throughput RF links, and multi-sensor synchronization. These requirements place enormous pressure on the UAV PCB architecture, especially in compact airframes where thermal, mechanical, and electromagnetic constraints are all tightly coupled. This is why high-density PCB design (HDI PCB),...

Modern wireless systems—from 5G radio units and phased-array antenna modules to automotive radar and satellite communication terminals—demand PCBs that deliver high RF power handling, exceptional phase stability, and ultra-low loss. As antenna modules continue to shrink while operating at higher frequencies, selecting the correct laminate becomes a mission-critical design decision. Among all mid-frequency RF substrates,...

High-density RF modules in 5G base stations, satellite payloads, and advanced IoT systems require compact multilayer PCBs with precise signal routing, minimal crosstalk, and high thermal resilience. Blind via technology allows for efficient vertical interconnects while reducing PCB stackup thickness, improving high-frequency performance, and maintaining signal integrity across densely packed layers. KKPCB integrates precision lamination,...

High-power telecom amplifiers in 4G/5G base stations, satellite uplinks, and RF power transmitters operate under extreme currents and elevated temperatures. Maintaining low insertion loss, minimized Joule heating, and stable impedance is critical to achieve high RF efficiency, thermal reliability, and signal integrity. Heavy copper PCB laminates (copper thickness 3–6 oz, Dk ~4.0, low Df @10...