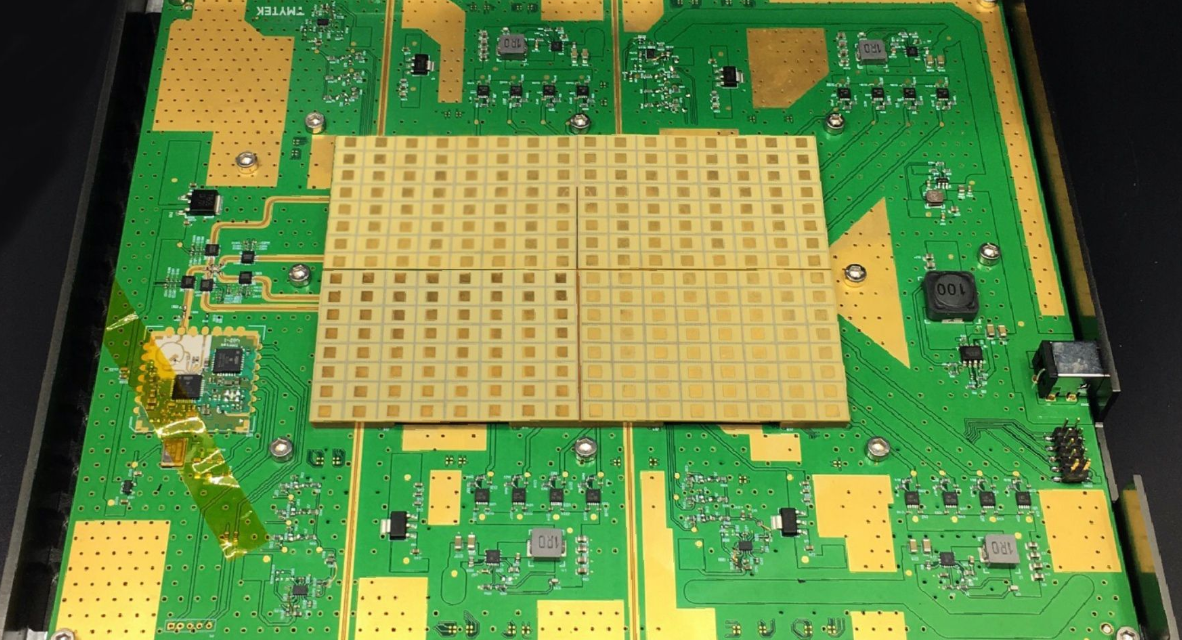

What Is a Low Loss PCB? A Low Loss PCB is a printed circuit board engineered to reduce signal attenuation, insertion loss, and phase distortion during signal transmission. It is essential for high-speed digital, RF, and millimeter-wave applications, where even small signal losses can significantly impact system performance. Low loss PCBs are widely used in...

HomeCategory

Advanced Engineering Technologies for PCB & PCBA Solutions - KKPCB

What Is a PCB Quotation Request? A PCB quotation request is the process of submitting design and technical requirements to a PCB manufacturer in order to receive pricing, lead time, and manufacturability feedback. It is a critical step before starting PCB prototype fabrication or mass production. An accurate PCB quotation request helps ensure cost transparency,...

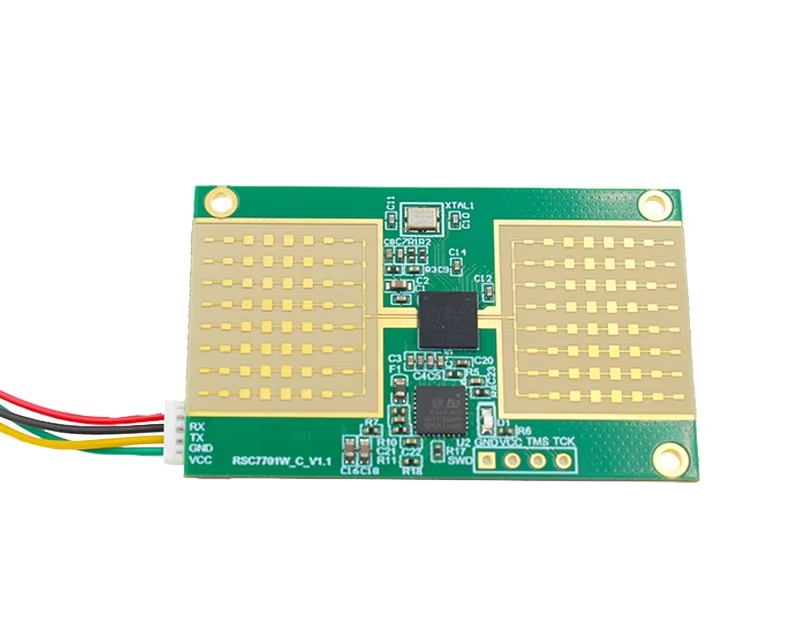

What Is a mmWave Module PCB? A mmWave Module PCB is a specialized printed circuit board designed to operate at millimeter-wave frequencies (typically 24 GHz to 110 GHz). These PCBs are used in compact RF modules where signal loss, impedance variation, and electromagnetic interference must be tightly controlled. mmWave module PCBs are core components in...

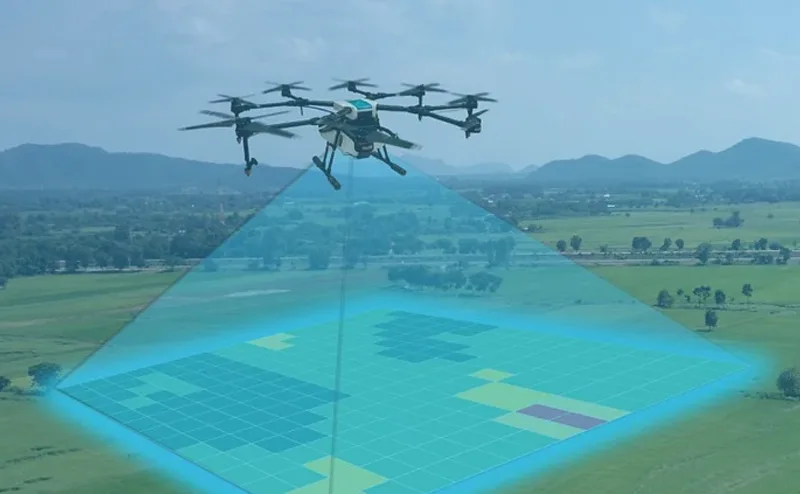

What Is a UAV PCB? A UAV PCB is a specially designed printed circuit board optimized for unmanned aerial vehicles and drones, where weight, signal integrity, high-frequency communication, and thermal reliability are critical. UAV PCBs integrate sensor modules, RF communication circuits, power management, and control systems into compact, high-density layouts suitable for aerial applications. Key...

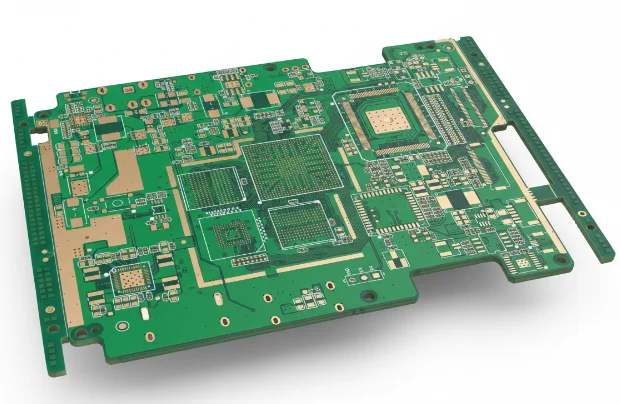

What Is a Blind Via PCB? A Blind Via PCB is a multilayer PCB that contains vias connecting an outer layer to one or more inner layers without going through the entire board. Unlike through-hole vias, blind vias enable high-density routing and space-saving designs, which are critical for HDI PCBs, high-frequency applications, and compact electronics....

What Is a Multilayer HF PCB? A Multilayer HF PCB is a printed circuit board with three or more layers designed specifically for high-frequency (HF) and RF signal transmission. These PCBs combine high-speed digital and RF design requirements with multilayer routing, providing: High signal density Controlled impedance Low-loss transmission Enhanced EMI/EMC performance They are widely...

What Is an Impedance Controlled PCB? An Impedance Controlled PCB is a printed circuit board engineered to maintain a precise and stable characteristic impedance along signal transmission paths. It is essential for high-speed digital signals and high-frequency RF signals, where impedance mismatches can cause signal reflection, loss, and distortion. Impedance controlled PCBs are widely used...

What Is a High Frequency Sensor PCB? A High Frequency Sensor PCB is a precision printed circuit board used in sensor systems that operate at RF or high-frequency ranges, such as radar sensors, mmWave sensors, imaging sensors, and industrial sensing modules. These PCBs must support accurate signal transmission, low noise, and high measurement stability. High...

What Is an ADAS PCB? An ADAS PCB is a specialized automotive PCB used in Advanced Driver Assistance Systems, such as radar, camera, LiDAR, and sensor fusion modules. These systems require high-speed data transmission, high-frequency signal processing, and exceptional reliability under demanding automotive conditions. ADAS PCBs form the core platform that connects sensors, processors, and...

What Is a 5G Router PCB? A 5G router PCB is a high-performance printed circuit board specifically designed for 5G wireless router systems. It supports high-frequency RF signals, high-speed digital data transmission, and multi-antenna architectures, which place extremely high demands on PCB materials, impedance control, and manufacturing precision. Compared with traditional router PCBs, 5G router...