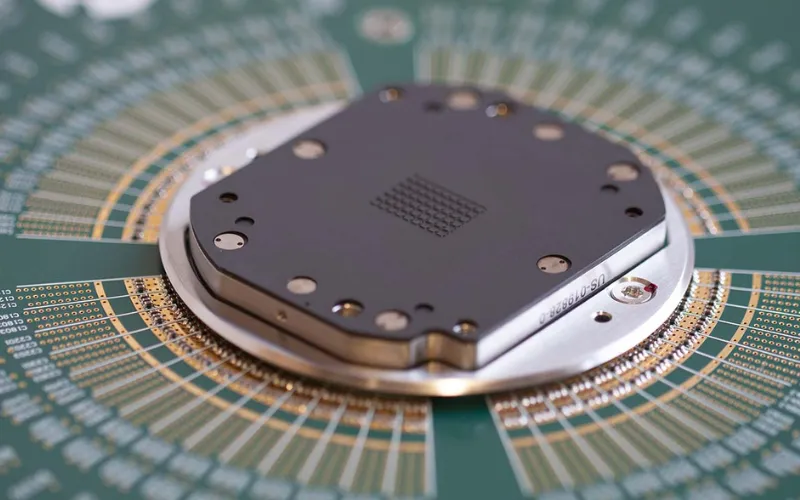

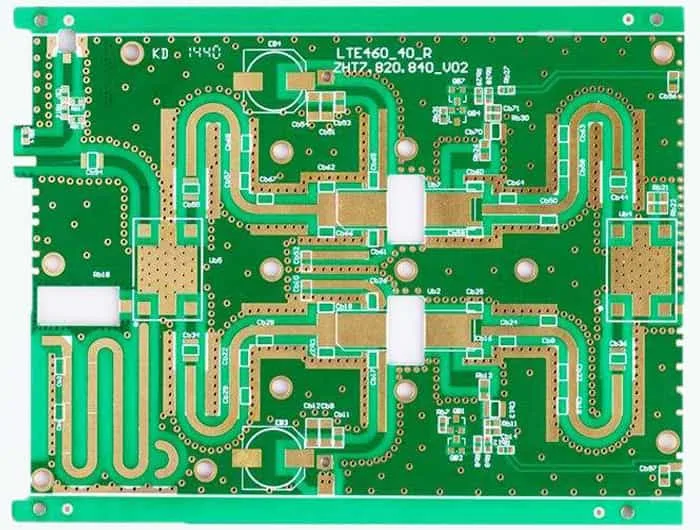

Probe Card PCB: High-Precision Substrates for Advanced Semiconductor Testing

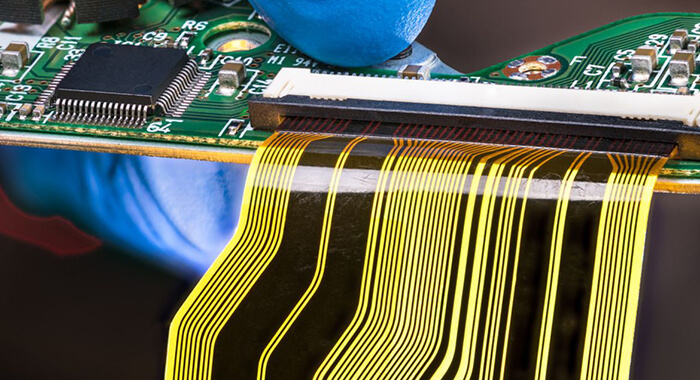

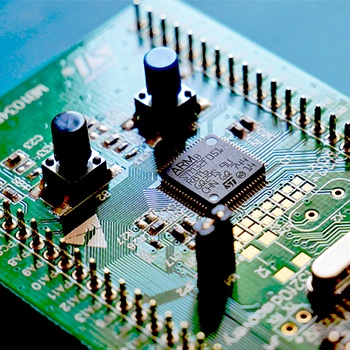

As semiconductor devices continue to scale in complexity and pin density, wafer-level testing requires extreme accuracy and repeatability. At the core of this process lies the probe card PCB, a critical interface that connects automated test equipment (ATE) to semiconductor wafers. A high-quality probe card PCB directly determines signal integrity, contact accuracy, and long-term test...