Automotive Radar PCB Manufacturing: Enabling Stable mmWave Performance for ADAS and Autonomous Vehicles

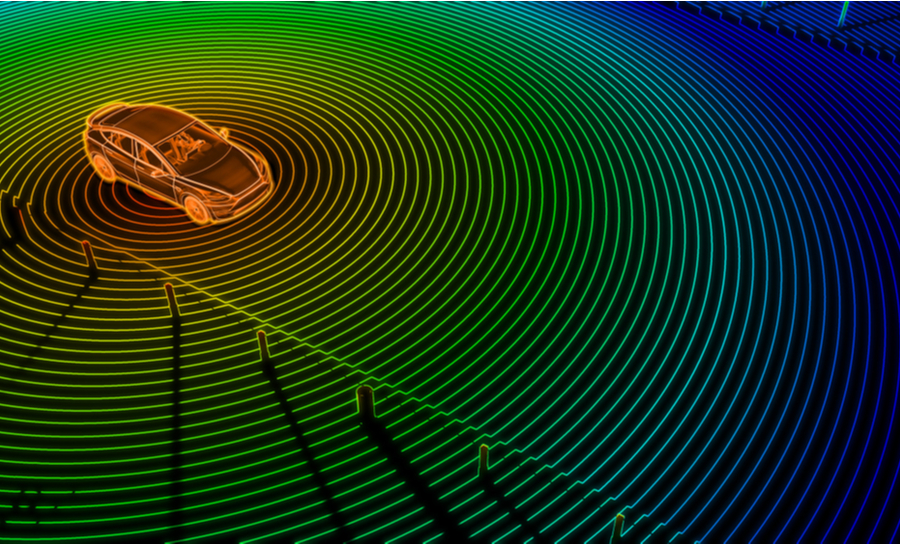

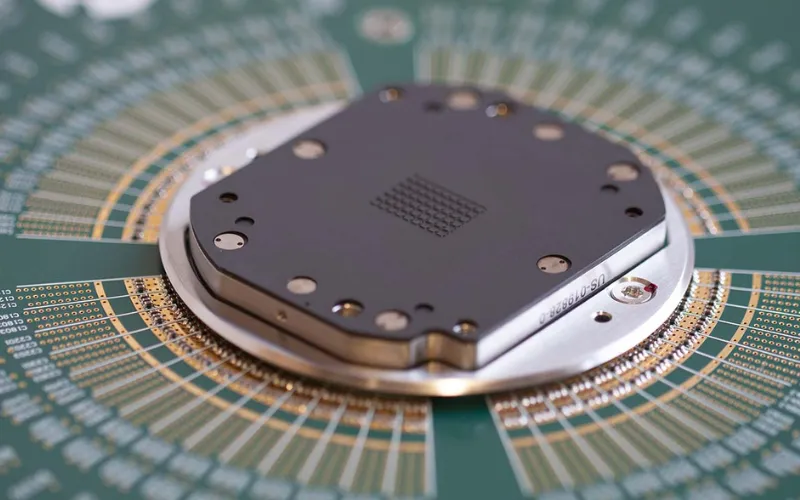

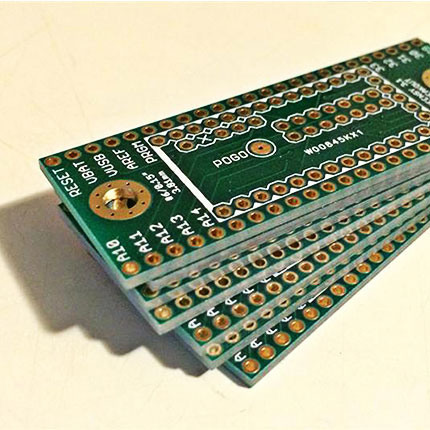

Automotive radar is a cornerstone technology for ADAS and autonomous driving, providing precise object detection in all weather and lighting conditions. Behind every reliable radar sensor is a carefully engineered automotive radar PCB, where manufacturing accuracy directly affects detection range, resolution, and system reliability. Automotive radar PCB manufacturing is not only about high frequency—it is...