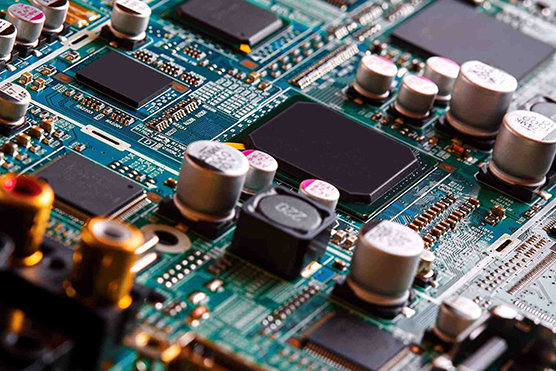

1. Introduction to Power Supply PCB Design Power supplies exist in a wide range of topologies, voltage levels, power ratings, and safety requirements, which makes power supply PCB design one of the most challenging areas in electronic engineering. Although the design choices are extensive, successful power supply PCBs always follow a set of fundamental layout...

HomeAuthor

kkpcba-Cindy - KKPCB - Page 2 of 75

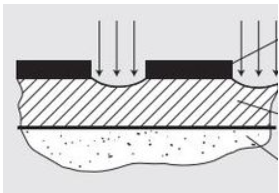

Is your conformal coating failing to properly wet the PCB surface?Are you experiencing pitting, fisheyes, poor flow, or coating delamination during or after coating? In many cases, these defects are not caused by the coating material itself, but by insufficient PCB surface energy. When the surface energy of the PCB substrate is lower than the...

The thermal conductivity of a printed circuit board (PCB) is largely determined by the properties of its dielectric layers, such as FR-4, high-TG materials, or thermally enhanced laminates.In low-power and high-reliability electronic devices, efficient thermal management is still critical to ensure long-term performance and stability. To improve heat dissipation, PCB designers commonly use thermal via...

With the rapid development of high-frequency and high-reliability electronic products, the limitations of traditional ENIG (Electroless Nickel Immersion Gold) surface finishes have become increasingly evident. EPIG (Electroless Palladium Immersion Gold) has emerged as an advanced alternative, especially for RF, microwave, and fine-pitch PCB applications. This article, optimized and technically interpreted by KKPCB, presents a comparative...

Control of Conductor Etching Process in Printed Circuit Boards Copper etching is one of the most critical steps in printed circuit board (PCB) manufacturing, as it directly determines the accuracy and reliability of conductive circuit patterns. The term “printed circuit board” originates from this process, since etching is the final stage of photolithography used to...

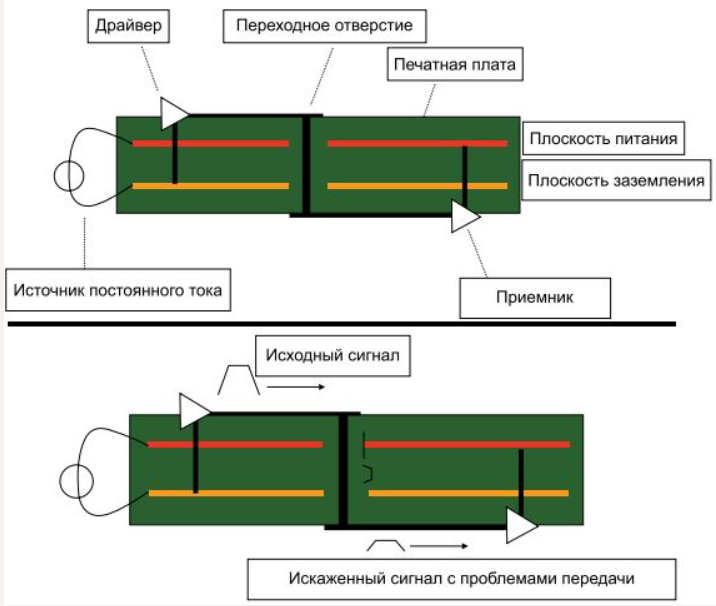

Preventing signal integrity issues on printed circuit boards (PCBs) is a challenging task for modern designers. Successful resolution requires a deep understanding of signal integrity design principles and practices. The introduction of faster logic families has led to simple printed circuit board (PCB) layouts no longer meeting signal integrity requirements. When working on high-speed designs, designers face...

The high level of competition in the modern automotive electronics market encourages manufacturers to constantly introduce new technologies and improve existing features, such as autopilot, automatic parking, emergency braking, keyless start, lane keeping control, and the like. Printed circuit boards (PCBs) are an essential and integral part of any electronic device in a vehicle. Their quality and...

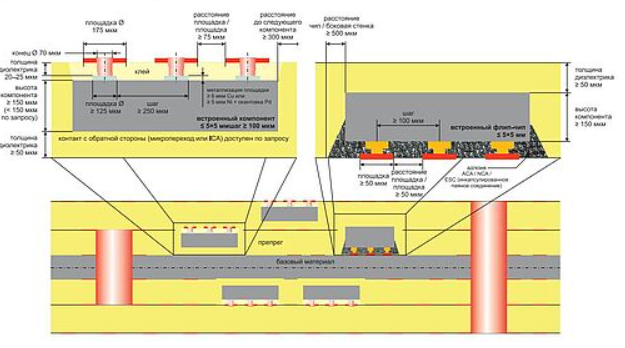

The Evolution of Embedded Component Technology in Modern Electronics Looking back at the evolution of computing—from Apollo workstations and early mainframes to ultrathin laptops and smartphones—the miniaturization of electronic components has always been central to technological progress. As devices become smaller and more powerful, engineers must balance form factor, functionality, PCB materials, signal integrity, power...

Warm-Metallurgy Breakthrough Expands the Capabilities of Inorganic Semiconductors Inorganic semiconductors are known for their excellent electrical properties but suffer from extreme brittleness at room temperature. This limitation has historically required complex, costly deposition technologies and made these materials unsuitable for flexible and wearable electronics. Recent research from Chinese scientists presents a major breakthrough, offering a...

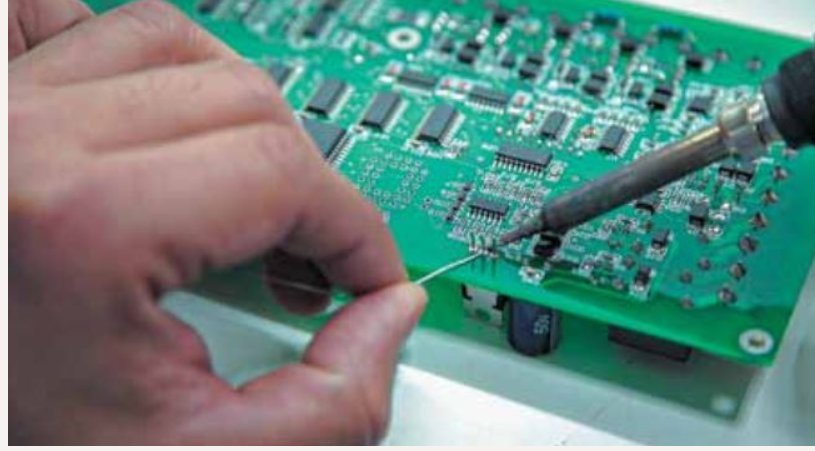

Perfect soldering of a printed circuit board is a very simple, yet very rare, phenomenon. How can this contradiction be explained? If perfect soldering is easy, then why so much rework and rework? The answer, of course, is that it is simple, but only if you know how, and also keep in mind that most...