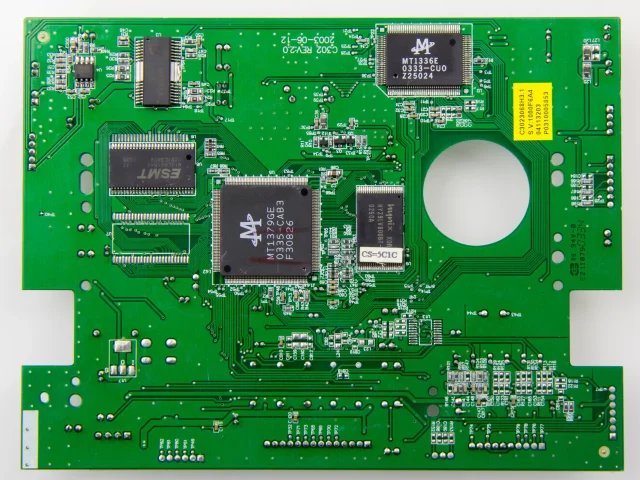

A Differential Pair PCB is a printed circuit board designed to route signals in pairs of two complementary traces, where one carries the positive signal and the other carries the negative signal. Instead of relying on a single-ended reference to ground, differential signaling transmits information through the voltage difference between the two traces, making it...

HomeAuthor

kkpcb04 - KKPCB - Page 13 of 65

A Megtron 6 PCB is a high-performance ultra low loss PCB built with Panasonic Megtron 6 laminate, designed for demanding high-speed digital and high-frequency signal applications. As next-generation electronics continue to push data rates higher—such as advanced SerDes links, high-speed networking, and data center backplanes—standard FR-4 and even some low-loss materials may struggle to meet...

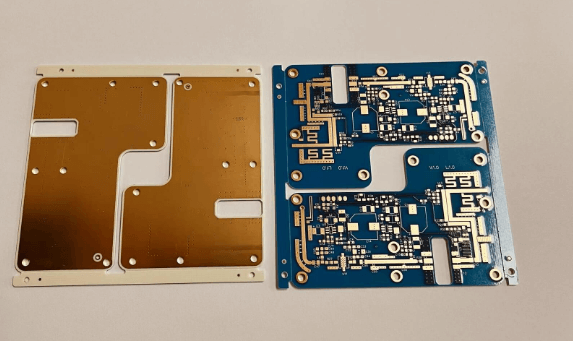

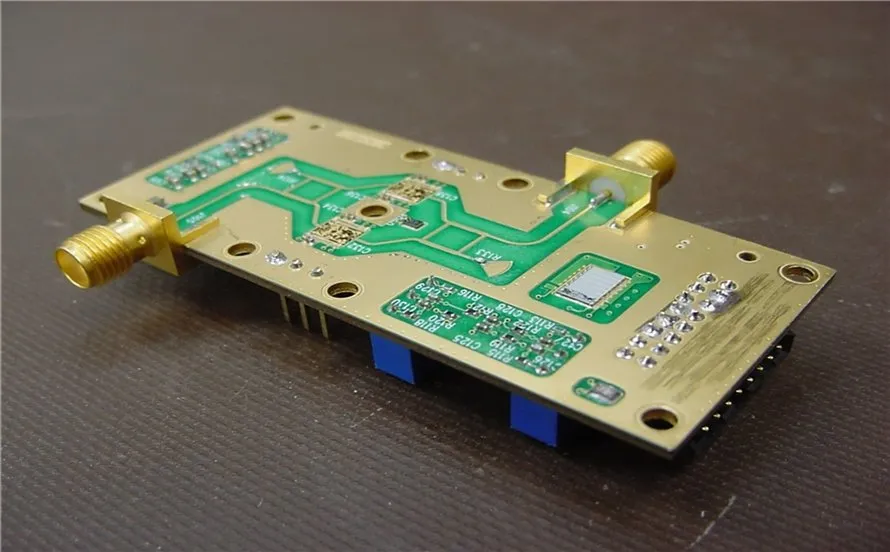

What Is an RO4003C PCB? An RO4003C PCB is a high-frequency printed circuit board manufactured using Rogers RO4003C laminate, a popular RF material designed for high-frequency and microwave applications. Compared with standard FR-4, RO4003C offers lower dielectric loss, more stable dielectric constant (Dk), and better performance for controlled impedance routing. Because of its excellent electrical...

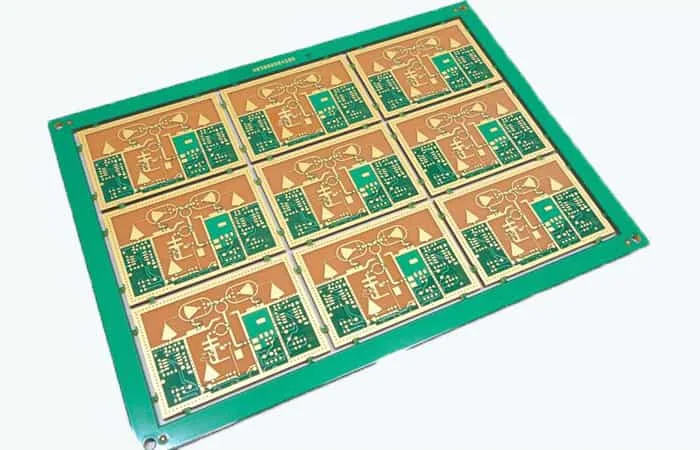

What Is a Rogers PCB? A Rogers PCB is a high-frequency printed circuit board manufactured using Rogers laminate materials, which are engineered for RF, microwave, and high-speed signal applications. Compared with standard FR-4, Rogers materials offer lower dielectric loss, more stable dielectric constant (Dk), and better electrical performance at high frequencies. Because of these advantages,...

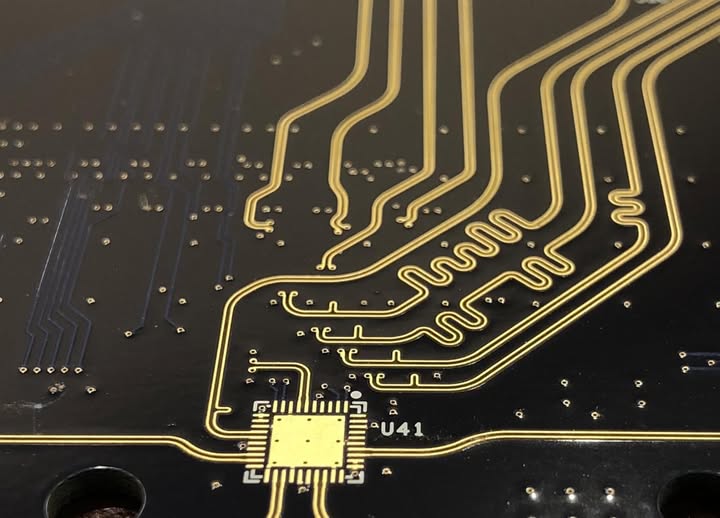

What Is a High Frequency Signal PCB? A High Frequency Signal PCB is a printed circuit board designed to transmit high-frequency electrical signals—typically in the MHz to GHz range—while maintaining signal integrity, minimizing loss, and reducing EMI. These PCBs are critical in applications such as RF communication, microwave devices, 5G modules, radar systems, high-speed networking,...

What Is an RF Trace PCB? An RF Trace PCB is a printed circuit board designed with optimized RF trace routing to carry radio frequency (RF) signals with minimal loss, stable impedance, and strong EMI control. RF traces are transmission lines that must maintain consistent electrical performance at high frequencies, typically from hundreds of MHz...

Differential Pair PCB: Controlled Impedance Routing for High-Speed and Low-Noise Signal Transmission

What Is a Differential Pair PCB? A Differential Pair PCB is a printed circuit board designed with differential signal pairs to transmit high-speed data with improved noise immunity and stable signal quality. A differential pair consists of two matched traces carrying equal and opposite signals, allowing the receiver to detect the voltage difference between them....

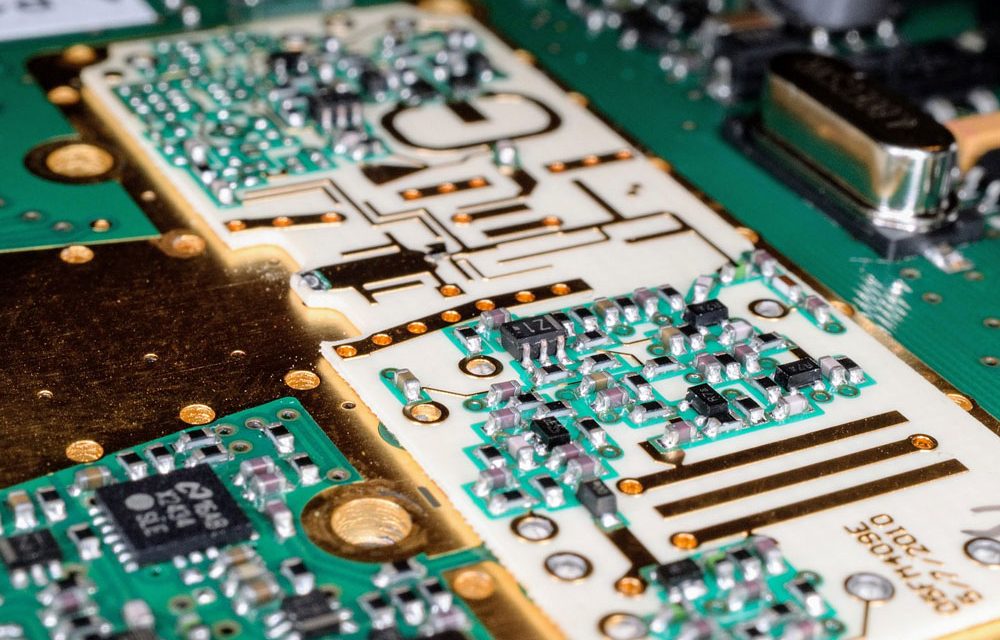

What Is a Fine Line PCB? A Fine Line PCB is a high-precision printed circuit board manufactured with ultra-thin trace width and tight trace spacing, enabling high-density routing for advanced electronic products. Compared with standard PCB technology, Fine Line PCB fabrication focuses on achieving smaller line/space (L/S), higher wiring density, and improved signal performance in...

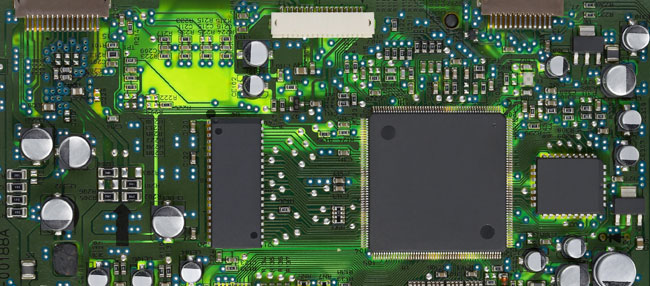

What Is a High Speed Logic PCB? A High Speed Logic PCB is a printed circuit board designed for high-speed digital logic signals that require stable timing, clean waveforms, and reliable data transmission. Unlike standard PCBs, a High Speed Logic PCB must handle fast edge rates, high-frequency harmonics, and strict signal integrity requirements for interfaces...

What Is a Power Integrity PCB? A Power Integrity PCB is a printed circuit board engineered to deliver stable voltage, low-noise power, and reliable current distribution to high-speed ICs such as CPUs, GPUs, FPGAs, ASICs, and high-density memory devices. In modern electronics, core voltages are getting lower while current demand is increasing, which makes power...