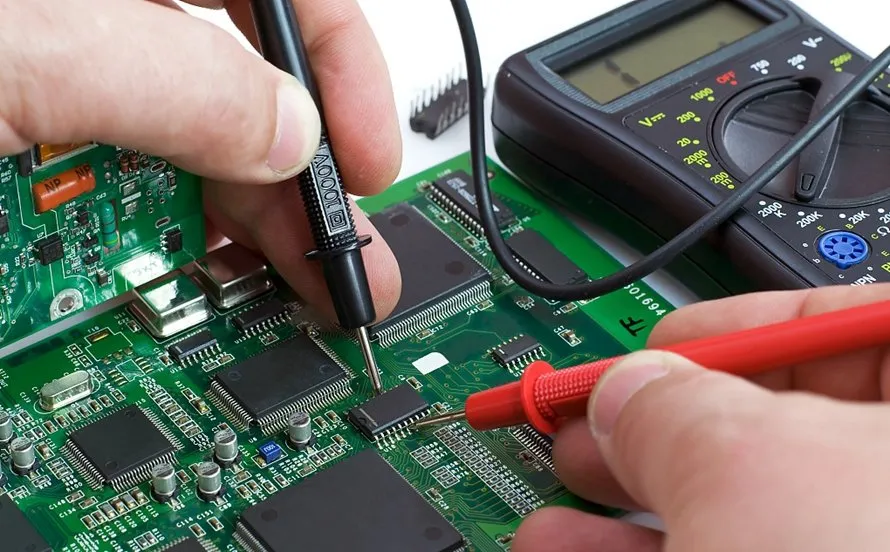

In today’s global electronics supply chain, many engineers and procurement teams prefer to source printed circuit boards directly from a PCB supplier direct—a factory-level manufacturer that eliminates intermediaries and delivers transparent pricing, faster lead times, and tighter quality control. A true PCB supplier direct partner provides direct access to PCB manufacturing expertise, supports rapid prototyping,...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

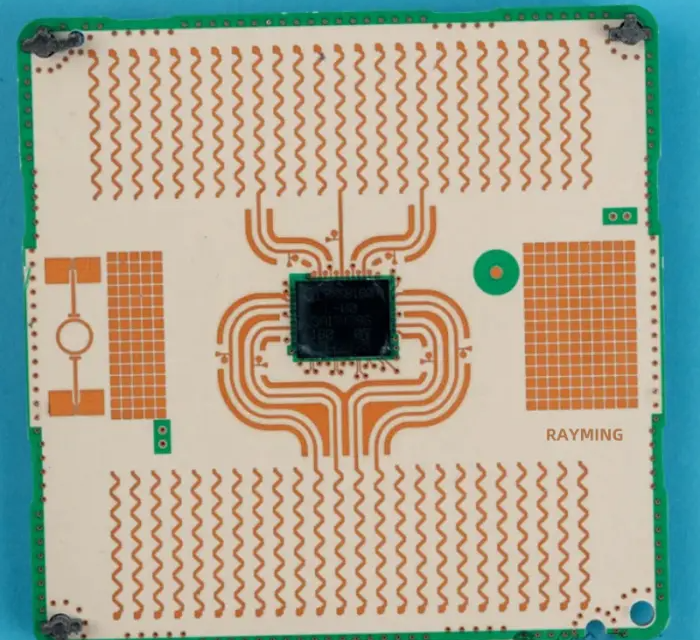

Radar modules used in automotive, aerospace, and industrial sensing systems operate at extremely high frequencies where signal loss and phase stability are critical. Selecting the right PCB material directly impacts detection accuracy and system reliability. Duroid 5880 PCB for radar module applications is one of the most trusted solutions for high-frequency and millimeter-wave radar designs....

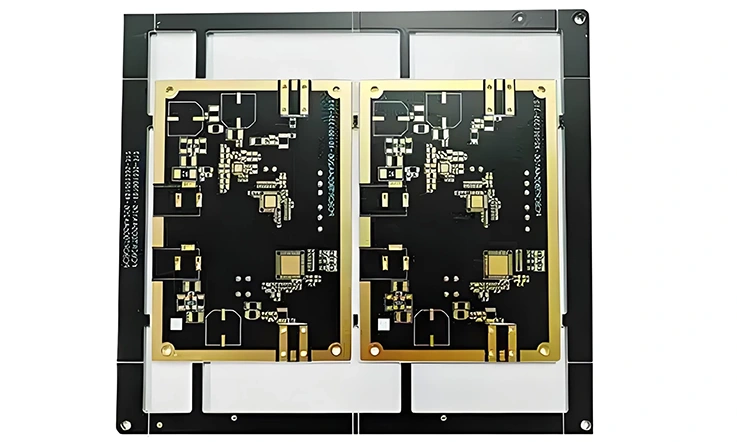

Automotive radar systems are a core component of modern ADAS and autonomous driving technologies. Operating at high frequencies such as 24 GHz, 77 GHz, and 79 GHz, these systems demand extremely stable RF performance and long-term reliability. Automotive radar PCB manufacturing plays a critical role in ensuring accurate signal transmission, detection precision, and system safety....

As operating frequencies and data rates continue to rise, signal loss becomes a critical concern in electronic system design. Choosing a reliable low loss high frequency PCB supplier is essential to ensure stable signal transmission, accurate impedance control, and consistent product performance. Low loss high frequency PCBs are widely used in RF, microwave, 5G, and...

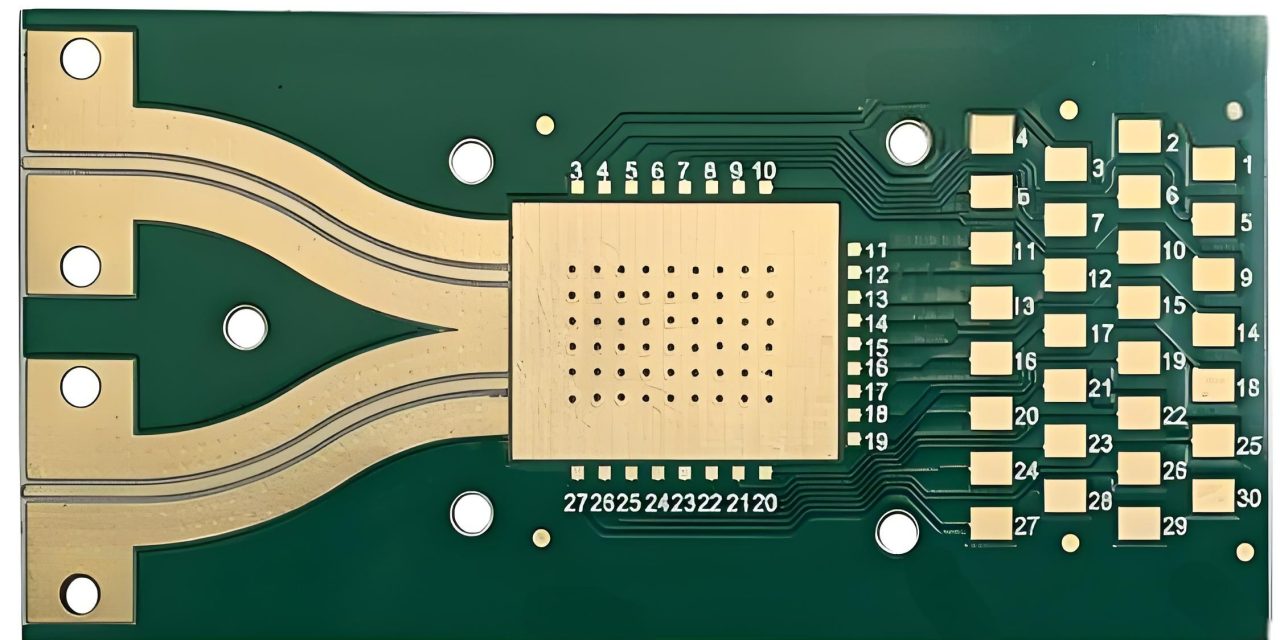

As data rates and operating frequencies continue to increase, signal integrity becomes a critical factor even at the prototype stage. A controlled impedance PCB prototype allows engineers to validate high-speed and RF signal performance before entering volume production. Accurate impedance control during PCB prototyping helps reduce reflections, minimize signal loss, and ensure design reliability from...

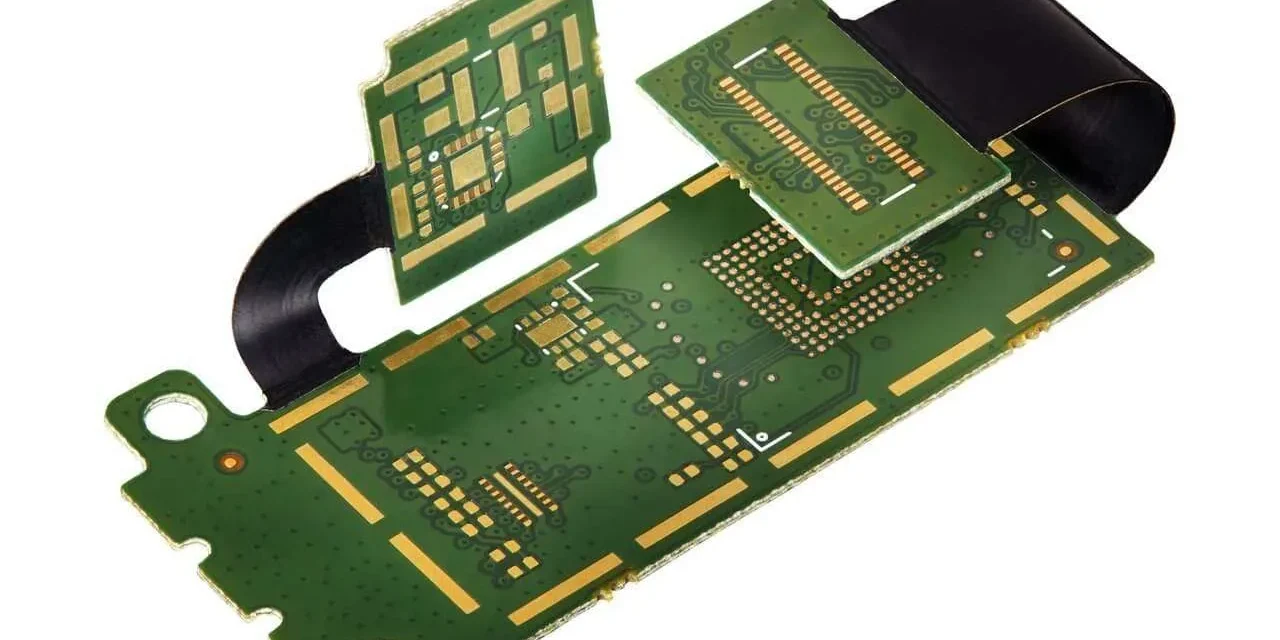

As electronic products become smaller, lighter, and more complex, the demand for integrated and space-saving interconnect solutions continues to grow. A professional multilayer rigid-flex PCB manufacturer provides advanced manufacturing solutions that combine the mechanical stability of rigid PCBs with the flexibility of flex circuits. Multilayer rigid-flex PCBs enable compact design, improved reliability, and reduced interconnection...

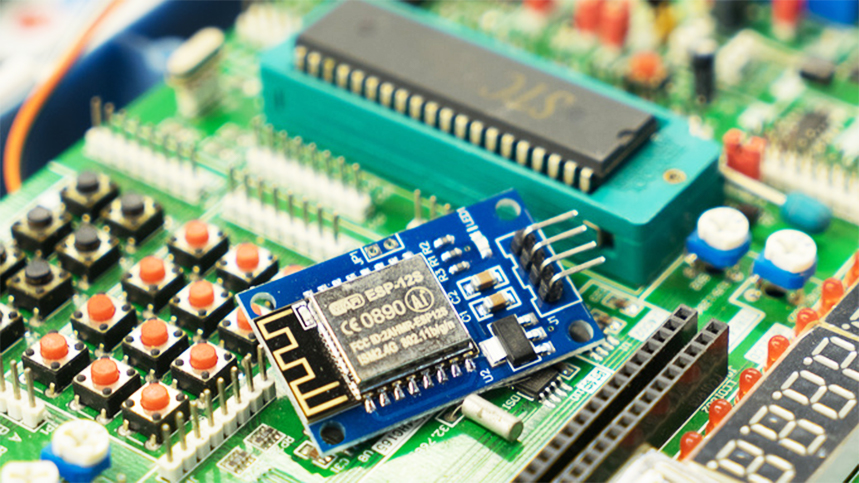

As IoT devices increasingly rely on wireless communication, RF and high-frequency circuit performance becomes critical from the earliest design stage. A high frequency IoT PCB prototype allows engineers to validate RF performance, antenna behavior, and high-speed signal integrity before moving into mass production. Reliable high frequency IoT PCB prototyping reduces development risk, shortens time to...

As 5G technology continues to evolve, 5G communication modules are becoming more compact, integrated, and performance-sensitive. 5G module PCB assembly plays a critical role in ensuring signal integrity, RF stability, and long-term reliability. Compared with conventional PCBA, 5G module assembly requires higher precision, stricter process control, and advanced testing capability. This article outlines the key...

As millimeter-wave (mmWave) technology becomes essential for 5G, automotive radar, and high-speed wireless systems, the selection of PCB materials plays a critical role in overall RF performance. Taconic RF-35 PCB for mmWave applications is a proven solution designed to deliver low loss, stable dielectric properties, and consistent performance at extremely high frequencies. Compared with conventional...

In 5G communication systems, antenna performance directly impacts signal coverage, efficiency, and data throughput. Selecting the right PCB material is critical, especially for sub-6 GHz and high-speed RF antenna designs. RO4003 PCB for 5G antenna applications is widely adopted due to its low loss, stable dielectric properties, and excellent manufacturability. Compared with conventional FR-4 materials,...