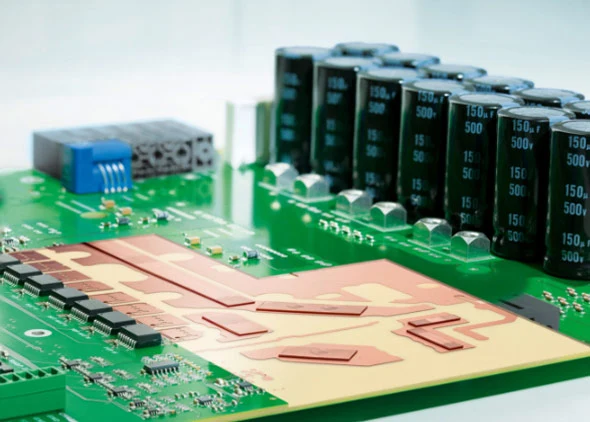

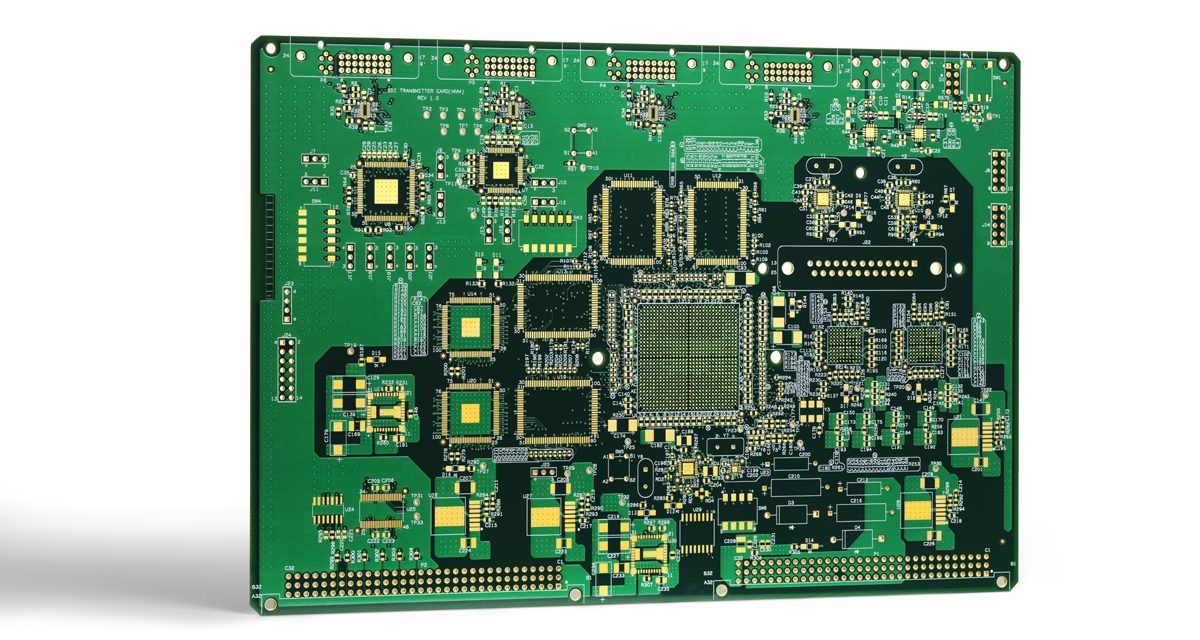

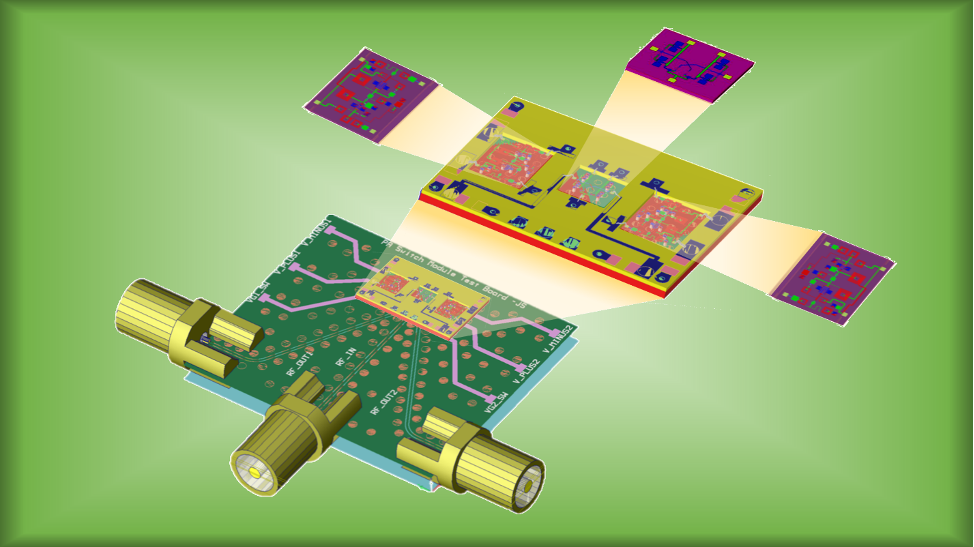

In high-volume semiconductor manufacturing, production testing must be fast, repeatable, and extremely reliable. At the center of this process is the Load Board PCB, a critical interface that connects automated test equipment (ATE) to the device under test (DUT). A well-designed Load Board PCB ensures that every device is evaluated under identical electrical conditions, enabling...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

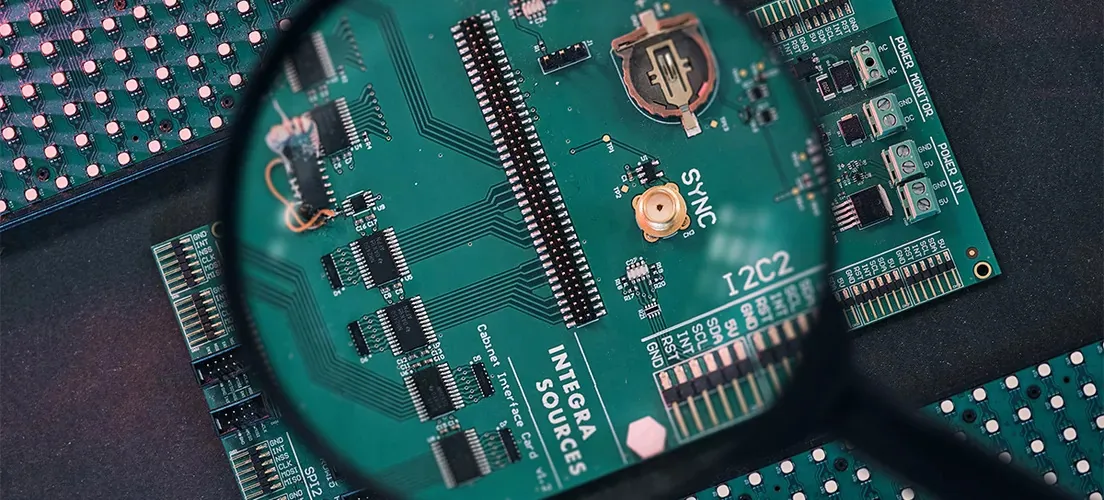

In semiconductor manufacturing, testing is not a single step—it is a continuous process that spans wafer probing, device validation, system-level testing, and mass production. At the core of this process lies the Semiconductor Test PCB, a specialized printed circuit board designed to deliver consistent electrical performance across every test stage. A well-designed Semiconductor Test PCB...

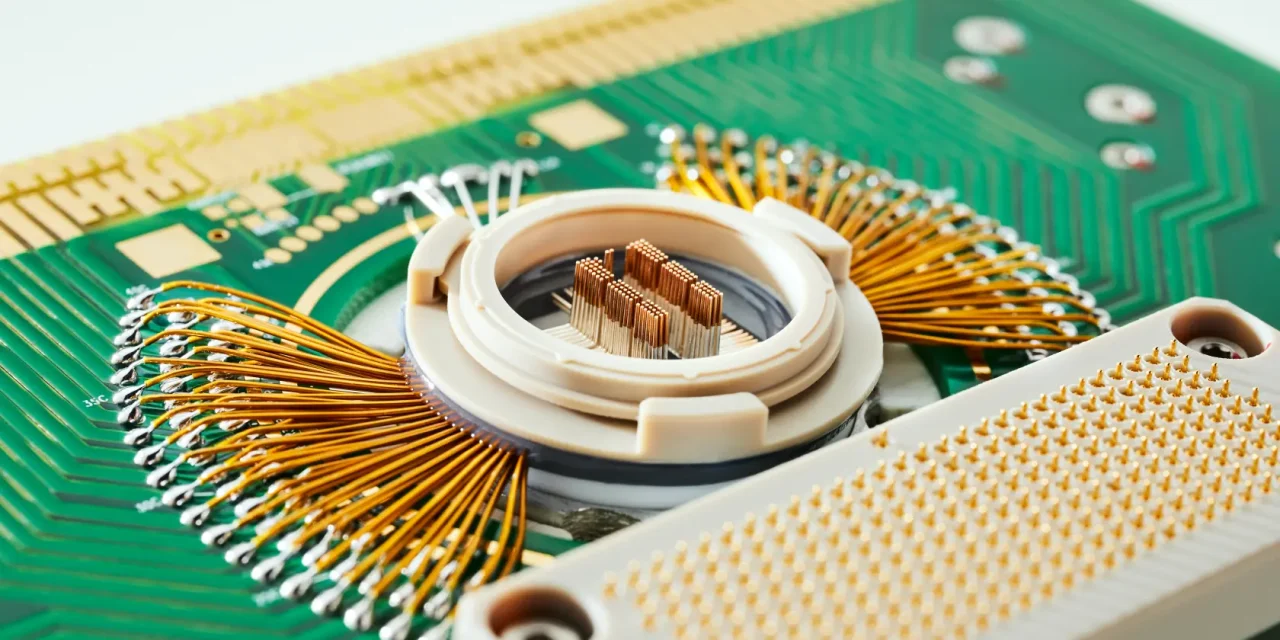

As semiconductor devices continue to scale down in size while increasing in performance, wafer-level testing demands extreme precision. At the heart of this process lies the Probe Card PCB, a critical platform that connects automated test equipment to microscopic probe needles touching individual die pads. A professionally manufactured Probe Card PCB directly determines probing accuracy,...

In modern semiconductor production, test accuracy must remain stable not only for one device, but across tens of thousands—or even millions—of test cycles. While ATE systems continue to advance in speed and precision, the ATE test PCB remains a decisive factor in determining whether test results are repeatable, reliable, and production-ready. A professionally engineered ATE...

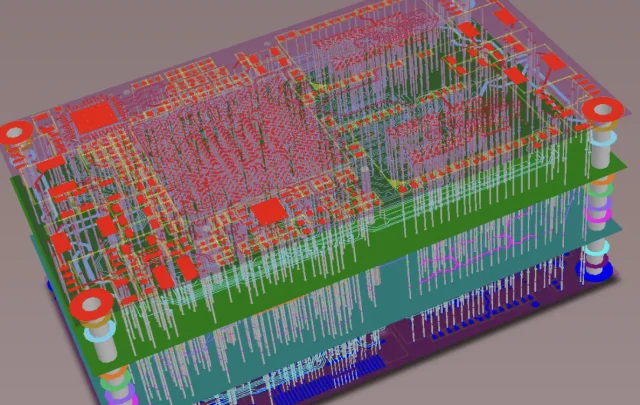

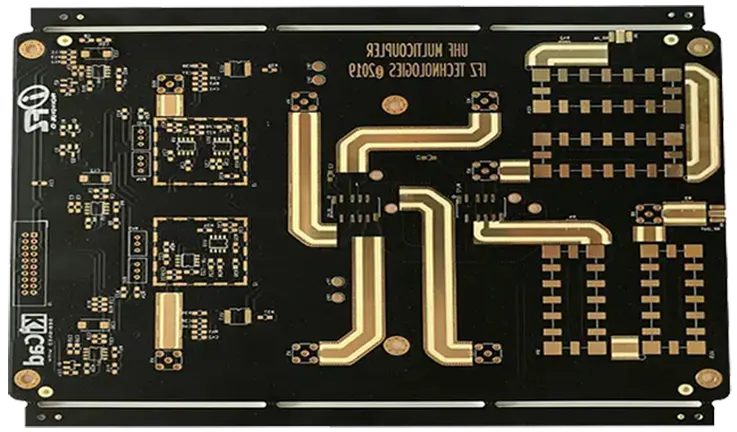

As semiconductor devices and electronic systems continue to increase in speed and complexity, test environments must deliver the same level of precision as the final product. The multilayer test PCB plays a critical role in ensuring accurate measurements, stable signal transmission, and repeatable test results across development and mass production. A well-designed multilayer test PCB...

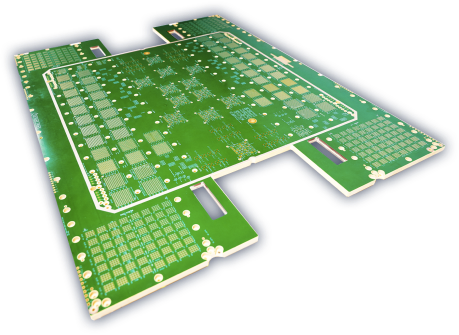

As electronic products continue to become smaller, faster, and more complex, traditional PCB technology often reaches its physical limits. HDI PCB (High-Density Interconnect PCB) technology was developed to overcome these constraints by enabling much higher routing density, improved signal integrity, and greater design flexibility. Today, HDI PCBs are widely used in high-speed digital systems, semiconductor...

As electronic devices continue to integrate more functionality into smaller form factors, the number of signal, power, and ground connections has increased dramatically. The high pin count PCB is specifically engineered to support dense interconnect requirements while maintaining stable electrical and mechanical performance. From semiconductor testing to high-speed communication systems, a professionally manufactured high pin...

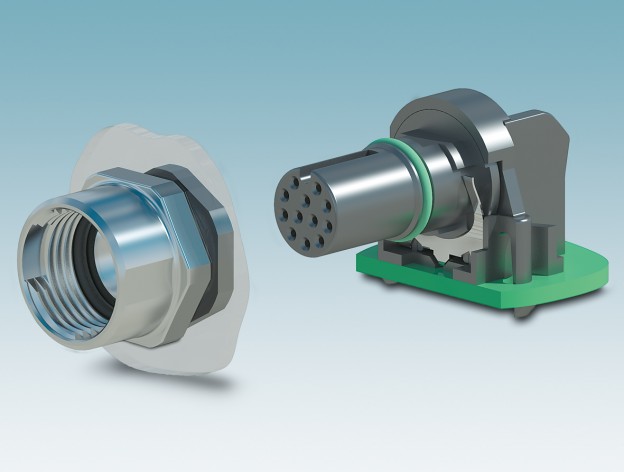

In semiconductor testing environments, stable electrical contact is just as important as tester accuracy. Even the most advanced ATE systems cannot deliver consistent results without a reliable interface between the device under test (DUT) and the test platform. The test socket PCB serves as this critical interface, directly influencing contact reliability, signal integrity, and test...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

5G mmWave PCB: Enabling Ultra-High-Frequency Performance for Next-Generation Wireless Systems

5G millimeter-wave technology is driving a new generation of ultra-fast wireless communication. Operating in frequency bands such as 24 GHz, 28 GHz, and 39 GHz, 5G mmWave systems require extremely strict control over signal loss, impedance accuracy, and manufacturing tolerances. At the heart of these systems lies the 5G mmWave PCB, a specialized high frequency...

As RF and microwave systems continue to move toward higher frequencies and tighter performance margins, material selection has become a critical design decision. Duroid 6002 PCB, developed by Rogers, is a high-performance laminate widely used in applications that demand low dielectric loss, excellent phase stability, and reliable high-frequency performance. A professionally manufactured Duroid 6002 PCB...