Introduction As IoT technology advances, so do the requirements for Printed Circuit Board (PCB) design and manufacturing. This blog extends the discussion on how IoT is driving innovations in PCB design, exploring deeper insights into new design techniques, material advancements, manufacturing challenges, and future prospects. Advanced Design Strategies for IoT-Enabled PCBs Design for Manufacturability (DFM) and Assembly (DFA)...

HomeAuthor

kkpcba-Cindy - KKPCB - Page 50 of 75

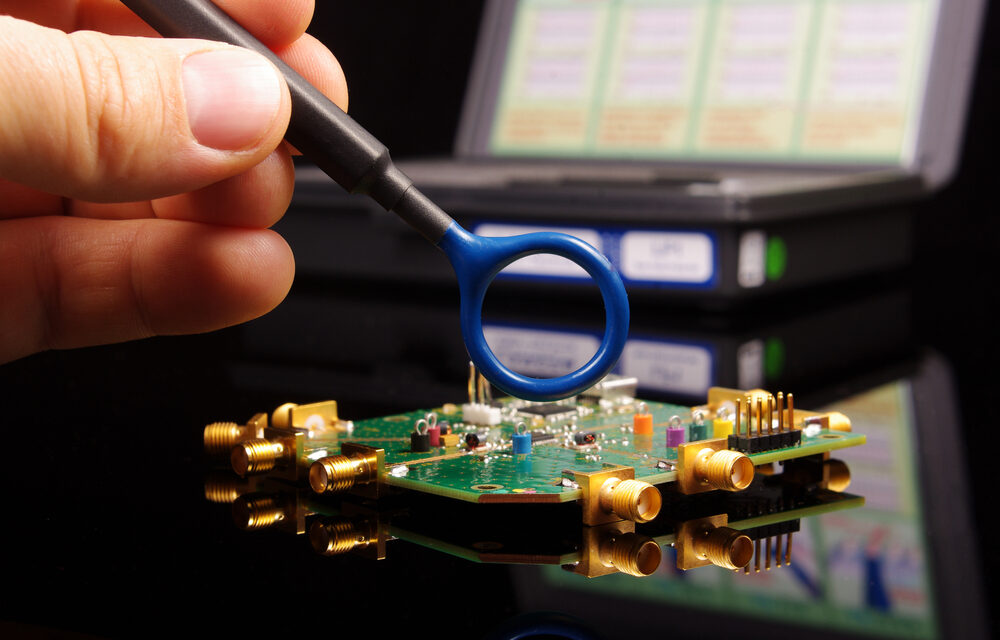

In the world of modern electronics, the proper functioning of electronic devices hinges on the precision and reliability of their components, with Printed Circuit Boards (PCBs) playing a central role. One of the key challenges in PCB design and manufacturing is managing Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI). Both of these factors can significantly impact the performance and...

China is pivotal in the global Printed Circuit Board (PCB) manufacturing industry. According to recent news reports, China has become the world’s largest PCB manufacturer, showing strong growth across multiple sectors. With the booming development of the electronics industry, particularly in consumer electronics, automotive electronics, and industrial automation, the demand for PCBs continues to rise, and China,...

In the world of electronics, the reliability and performance of Printed Circuit Boards (PCBs) are critical to the overall functionality of devices. Whether it’s consumer electronics, automotive systems, industrial machinery, or medical devices, PCBs’ performance directly impacts electronic products’ quality, safety, and durability. This is why PCB testing standards are vital in ensuring these crucial...

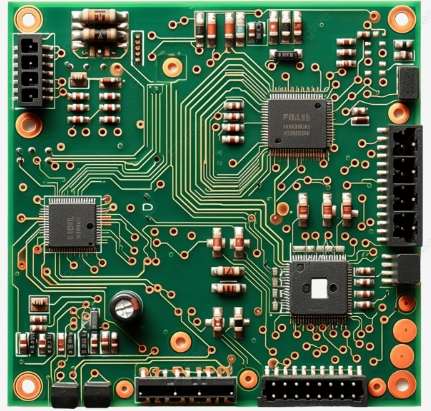

Industrial PCB Assembly KKPCB has become a one-stop shop when it comes to high-quality industrial PCB assembly. With over 10 years of experience in manufacturing and assembling a wide range of PCBs, KKPCB is a trusted choice for many customers. With the latest technology, equipped with a team of experts and industry best practices, we...

In the modern industrial system, printed circuit boards (PCBs) are the cornerstone of electronic products. From simple household appliances to complex aerospace equipment, PCBs are everywhere, assuming functions such as connection, support, and integrated circuits. With the advent of Industry 4.0, the mass production of PCBs not only needs to meet demand in terms of quantity, but...

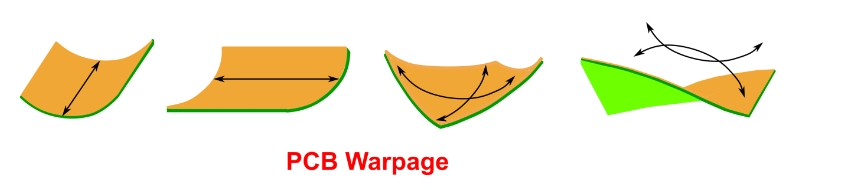

Definition and Industry Standards Printed Circuit Board (PCB) warpage refers to the phenomenon that the PCB plane bends or deforms due to various reasons during the manufacturing, storage or use of the PCB. This deformation may be local or overall, and is usually manifested as the PCB no longer remaining flat. Different application fields and industries...

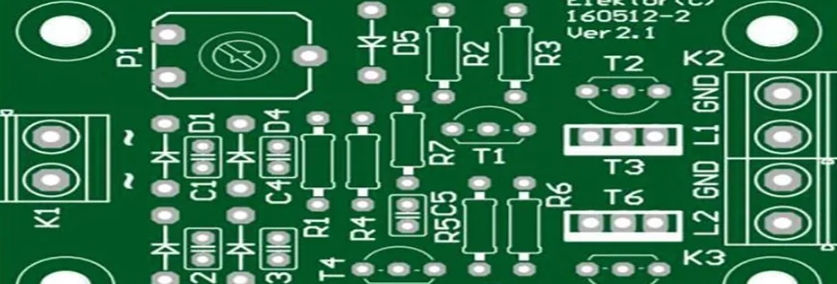

PCB solder mask is one of the important components in the PCB process. In-depth knowledge of solder mask will help engineers design PCBs with better functions and quality. This article will explore the composition of PCB solder mask and its important role. Composition of PCB solder mask Resin Resin is the basic component of PCB solder...

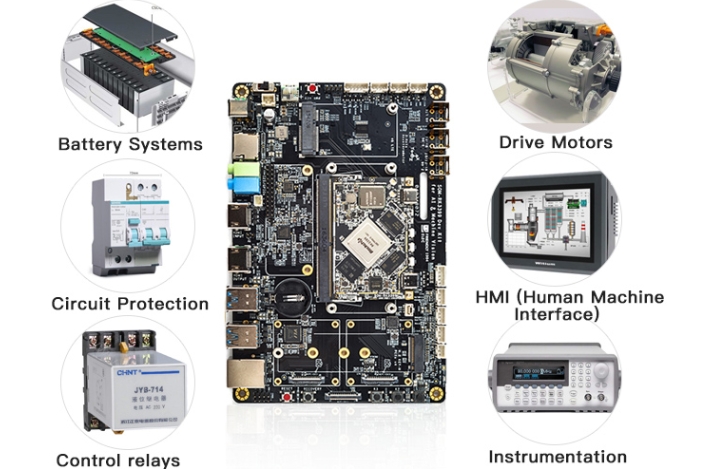

An industrial PCB must remain stable under harsh conditions. Therefore, it has features that are rugged enough to withstand extreme environments. This article will help you understand how it differs from conventional circuit boards, its manufacturing requirements, and example applications in the real world. What is an industrial printed circuit board? An industrial PCB is a circuit board...

In the automotive sector, electronics are increasingly becoming a decisive factor. This creates a dilemma for engineers. On one hand, their products must provide ever-improving performance, on the other hand, price per volume remains a key consideration. Automotive PCBAs help replace diesel injection pump chips, which include immobilizers and ZDCAN. People should choose automotive PCBAs correctly...