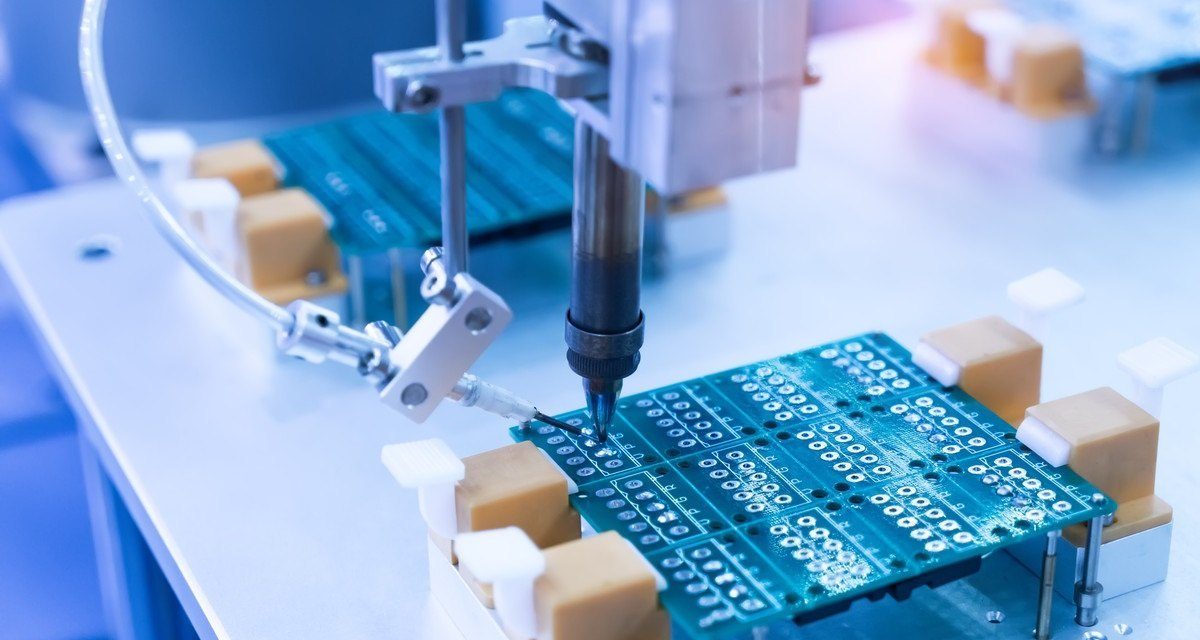

Fast and accurate PCB quotation is no longer a luxury—it is a critical enabler for modern hardware development. Whether the goal is prototype validation or high-volume mass production, incomplete design data often leads to delays, miscommunication, and multiple rounds of clarification. By providing complete engineering files such as the Gerber, BOM, stackup, and material specifications,...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

Rapid electronics development has entered an era where design cycles are measured not in months but in weeks. From IoT edge devices to next-generation communication modules and automotive sensing platforms, engineers must iterate faster while maintaining electrical performance, manufacturability, and long-term reliability. PCB prototypes sit at the heart of this acceleration. When engineered correctly, they...

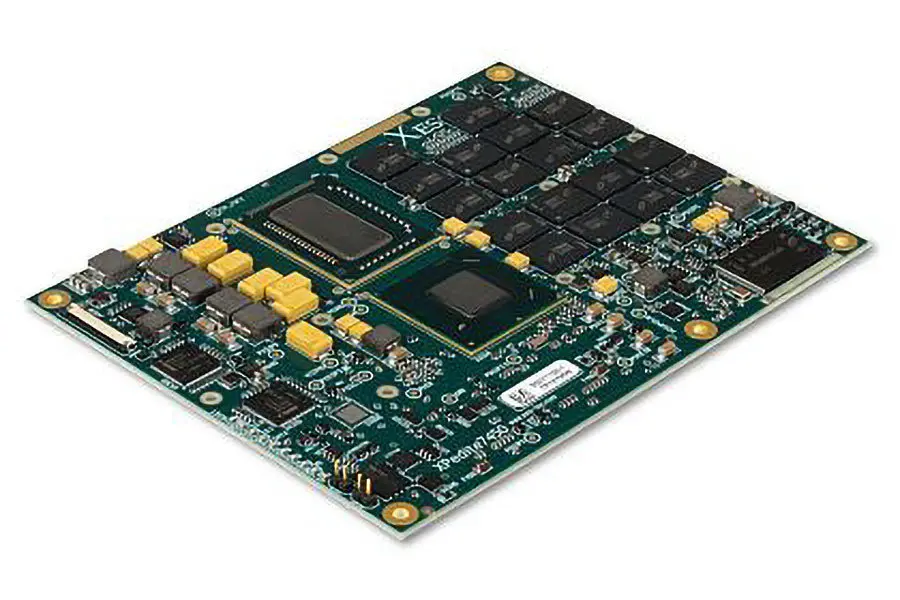

Multi-band wireless modules are moving toward increasingly complex RF transceiver architectures, supporting simultaneous operation across sub-6 GHz, C-band, and mmWave channels. As bandwidth expands and carrier aggregation becomes standard, the performance of the RF transceiver PCB becomes a controlling factor in overall system efficiency. Maintaining phase coherence, thermal stability, and low-loss RF routing requires PCB...

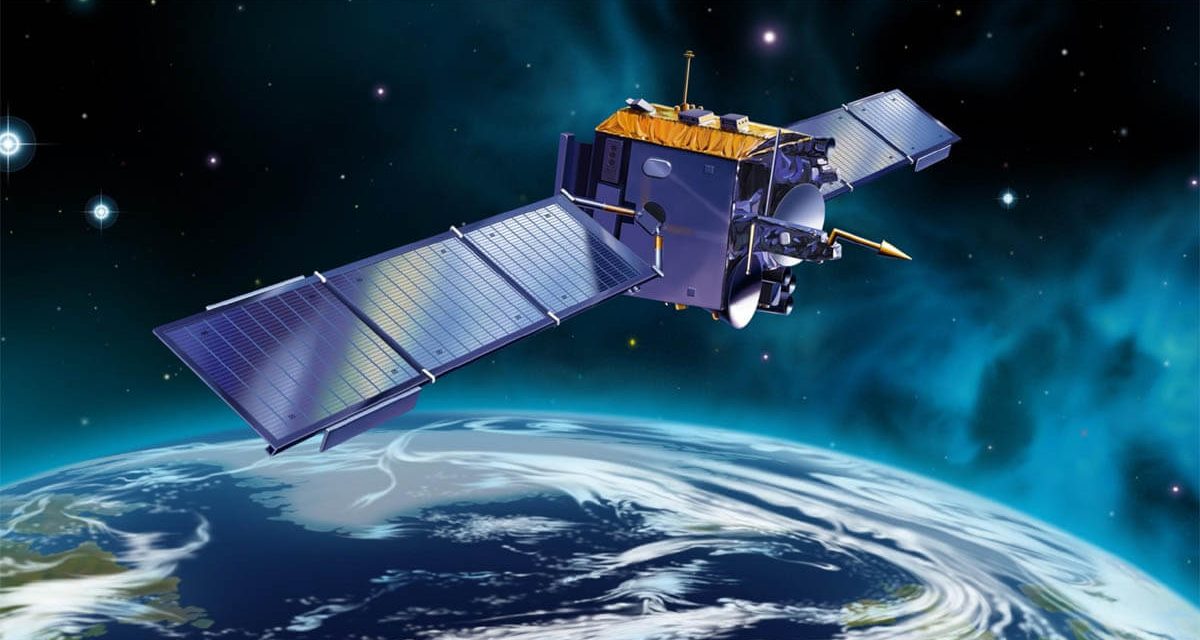

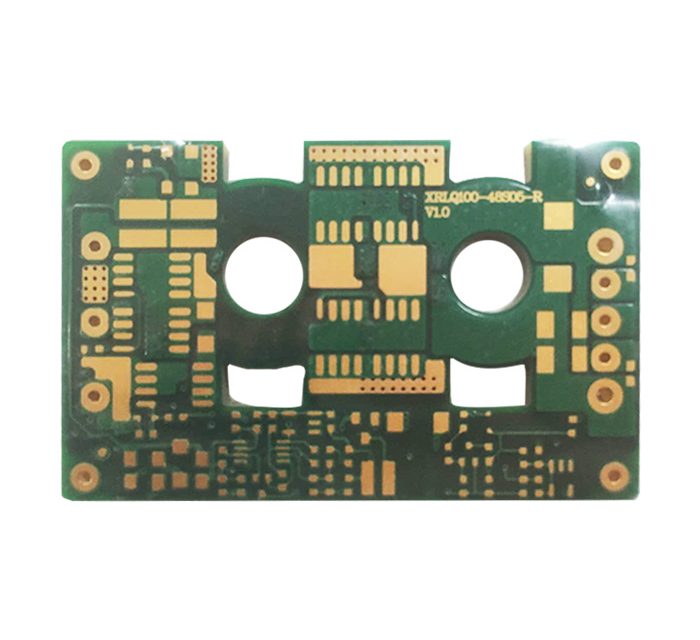

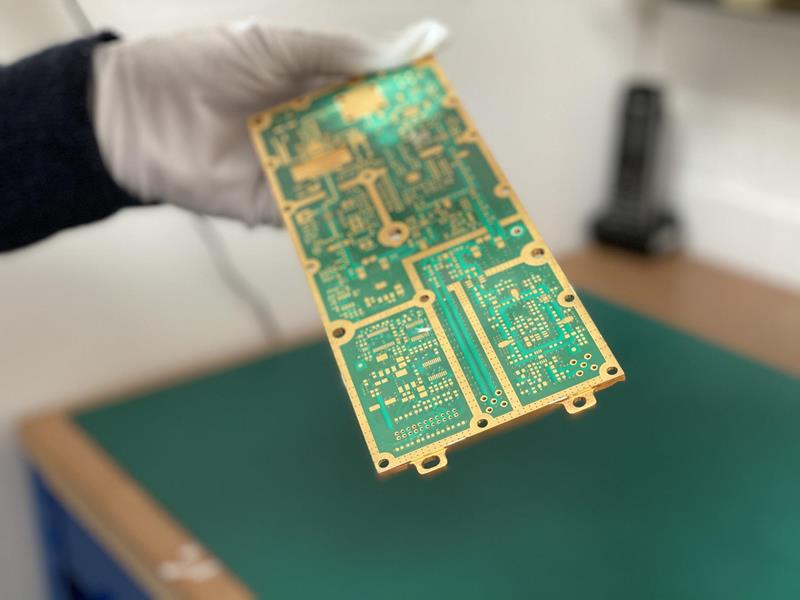

The shift toward high-throughput satellites, beam-steerable phased arrays, and broadband constellations has transformed how engineers design the satellite PCB at the core of every RF payload. In orbit, a PCB cannot rely on airflow, enclosure shielding, or serviceability. The board must deliver low-loss RF routing, stable dielectric behavior, and consistent electrical performance throughout years of...

Power electronics continue to advance toward higher efficiency, greater power density, and more compact architectures. From industrial motor drives to renewable energy inverters and high-current battery systems, modern equipment demands circuit boards that can withstand extreme electrical and thermal stress. At the core of these high-power platforms is the Heavy Copper PCB, a specialized board...

Customer CaseElectronics Industry NewsEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

ADAS PCB: The Hidden Backbone Behind Safer, Smarter Driving

Advanced driver-assistance systems (ADAS) have shifted from premium features to mainstream safety requirements across global automotive platforms. Functions such as adaptive cruise control, automatic emergency braking, lane-keeping assistance, and highway piloting depend on a dense ecosystem of sensors and computing modules. At the center of this ecosystem lies a critical but often overlooked component: the...

Electronics Industry NewsCustomer CaseEngineering TechnologiesPCB DesignPCB ManufacturingPCB Materials

Enhance Power Handling and Phase Stability Through Advanced Satellite PCB Materials in Ka- and Ku-Band Transceiver Modules

Ka- and Ku-band satellite transceivers demand high-frequency PCBs capable of handling elevated RF power while maintaining tight phase stability and low insertion loss. These modules operate in dense multilayer architectures, often within confined payloads, where thermal stress, EMI, and mechanical reliability directly impact signal fidelity and long-term performance. Advanced satellite PCB materials deliver low-loss dielectric...

Modern 5G and emerging 6G networks require RF transceivers capable of operating at millimeter-wave frequencies, supporting multi-band transmission with high linearity and low insertion loss. RF modules must withstand high RF power levels while preserving signal integrity, phase stability, and thermal reliability. Advanced RF transceiver PCB laminates provide low-loss dielectric properties, tight impedance control, and...

Energy Storage Systems (ESS)—from large-scale Battery Energy Storage Systems (BESS) to EV battery packs, industrial UPS units, and hybrid inverters—operate under sustained electrical and thermal stress. High charging currents, repeated load cycles, and fast switching from power semiconductors all demand a PCB platform that can withstand extreme conditions without degradation. This is exactly where Heavy...

Modern data center networks depend on multi-gigabit signal transmission, low-latency switching, and phase-coherent high-speed channels. As switching fabrics migrate from 25G/40G toward 100G/200G/400G architectures, even micro-scale distortions in dielectric properties or copper structures can degrade eye diagrams, reduce SNR, and trigger packet loss.This is why Low Loss PCB stackups—built with engineered dielectric materials and ultra-controlled...