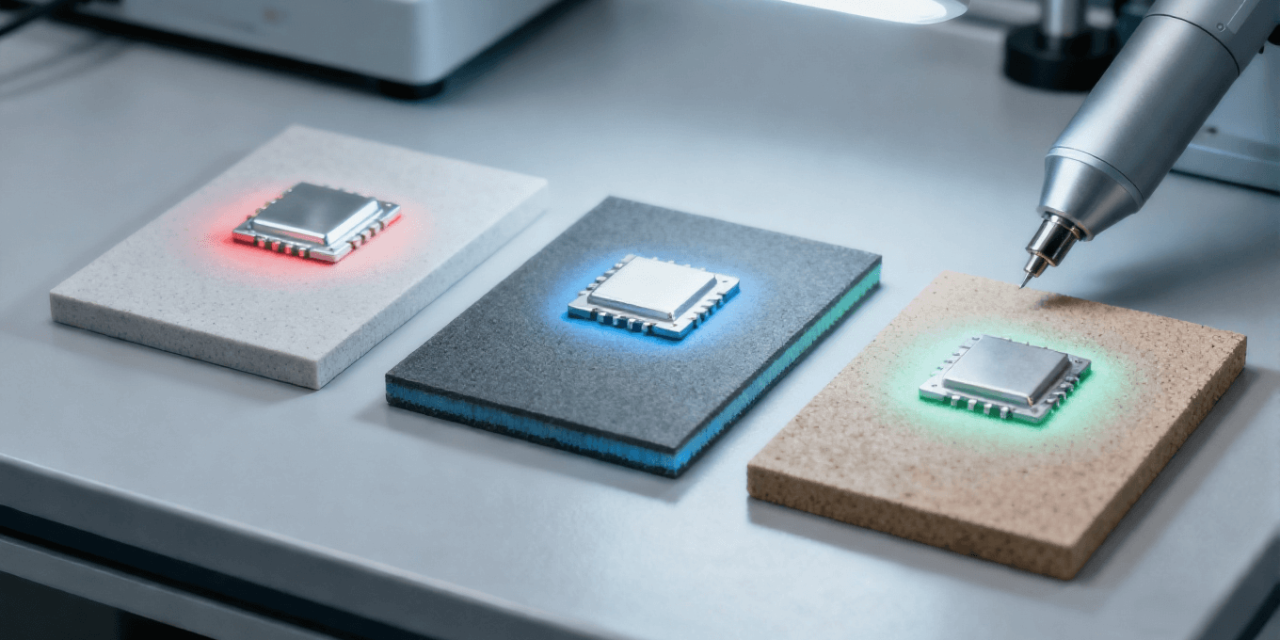

Silicon Carbide (SiC) PCB technology is transforming the landscape of high-power, high-frequency, and high-temperature electronics. As electric vehicles, renewable energy converters, aerospace systems, and industrial automation demand greater efficiency and reliability, SiC PCBs provide the thermal conductivity, voltage endurance, and switching performance required for next-generation power platforms. Unlike traditional FR-4 or low-temperature laminates, SiC PCB...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

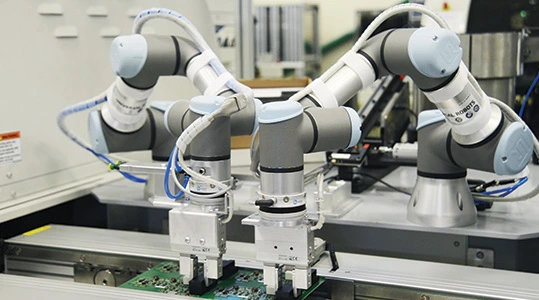

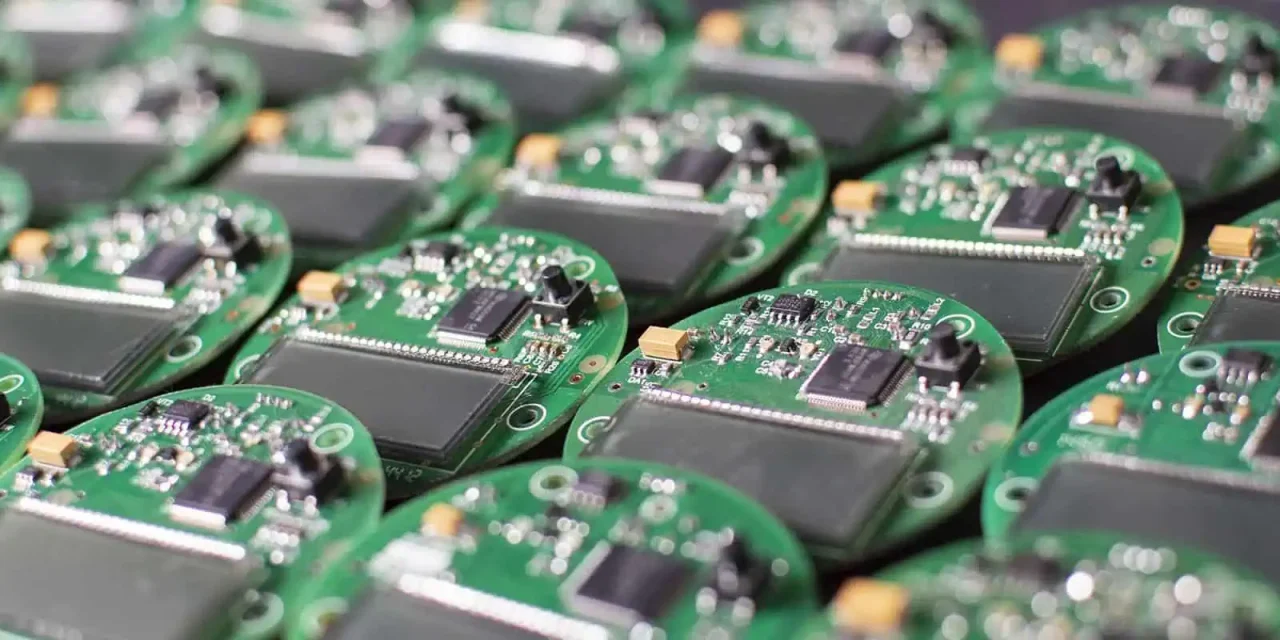

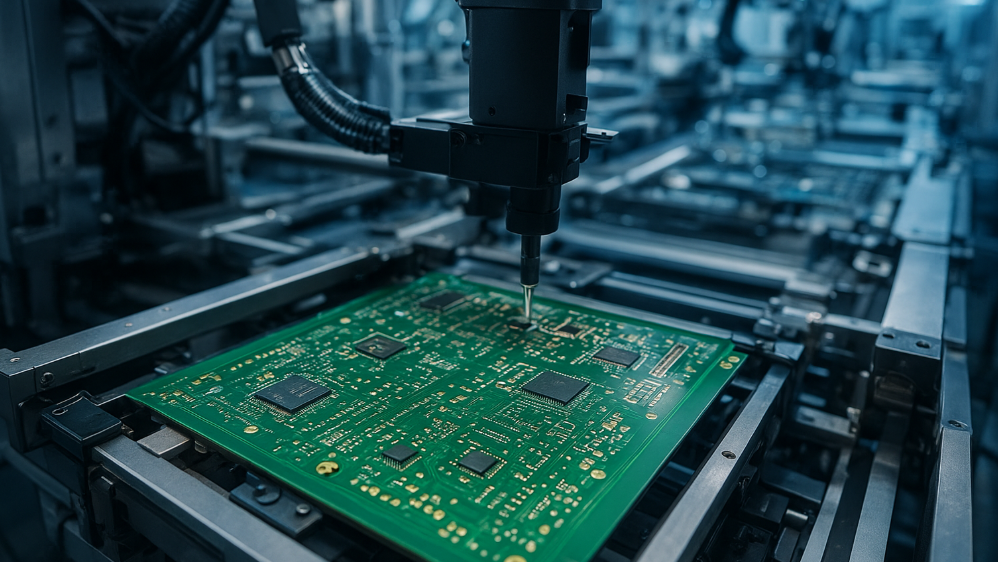

Modern robotics systems—whether industrial robots, autonomous mobile robots (AMRs), AGVs, or collaborative robots—depend on advanced Robotics PCBs as the central platform for sensing, computation, and motion control. As robotic applications expand into high-precision manufacturing, warehouse automation, healthcare, and defense, the engineering requirements for Robotics PCB design continue to escalate.This article explores the core engineering principles...

Silicon Carbide (SiC) PCBs are rapidly becoming essential for advanced power electronics, electric vehicles, aerospace systems, and industrial automation due to their ability to operate at higher temperatures, voltages, and frequencies than traditional FR-4 or standard ceramic substrates. SiC PCBs integrate wide-bandgap semiconductor technology directly with optimized thermal and electrical performance to support next-generation applications....

Modern industrial automation, autonomous robots, and collaborative robotic systems depend heavily on Robotics PCBs as the central electronic platform for control, sensing, and communication. Engineers designing Robotics PCBs face unique challenges: ensuring low-latency signal transmission, maintaining power stability for high-current actuators, integrating a diverse set of sensors, and protecting sensitive electronics from electromagnetic interference. 1....

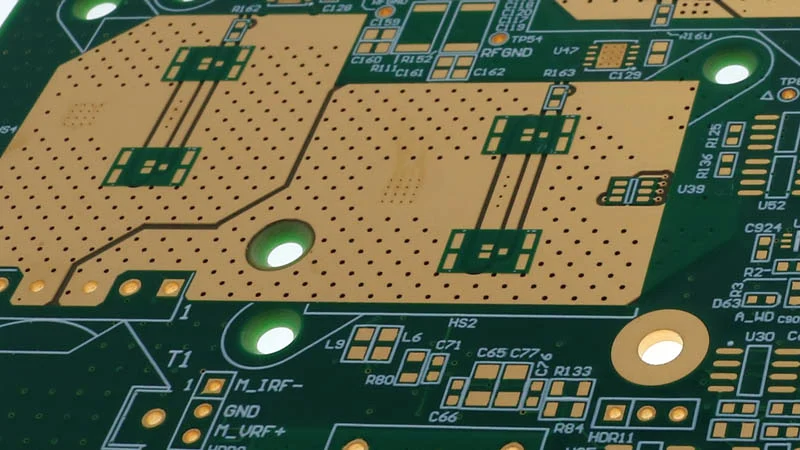

As microwave, satellite, radar, and millimeter-wave systems move deeper into high GHz operating regions, engineers require PCB materials with ultra-stable dielectric behavior, extremely high Dk, and exceptionally low loss. This is where Duroid 6010 PCB—based on Rogers RT/duroid® 6010LM—becomes a foundational choice for critical RF and microwave engineering. With a dielectric constant (Dk) of ~10.2,...

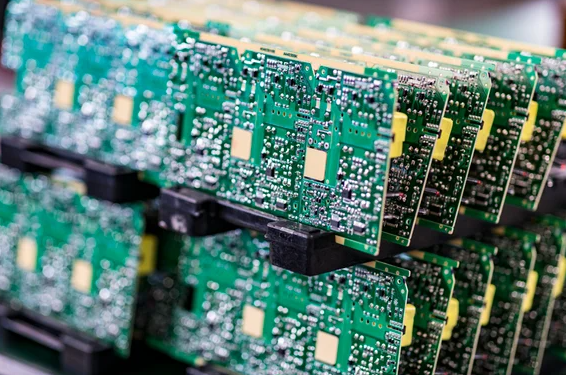

Industrial Automation PCB engineering sits at the core of modern manufacturing, robotics, and process-control systems. In factory environments filled with electrical noise, high temperatures, continuous vibration, and mission-critical timing demands, the Industrial Automation PCB must deliver unwavering reliability, low signal distortion, and stable power delivery. As factories evolve toward smart, interconnected, high-speed architectures, the expectations...

Industrial Automation PCB engineering sits at the core of modern manufacturing, robotics, and process-control systems. In factory environments filled with electrical noise, high temperatures, continuous vibration, and mission-critical timing demands, the Industrial Automation PCB must deliver unwavering reliability, low signal distortion, and stable power delivery. As factories evolve toward smart, interconnected, high-speed architectures, the expectations...

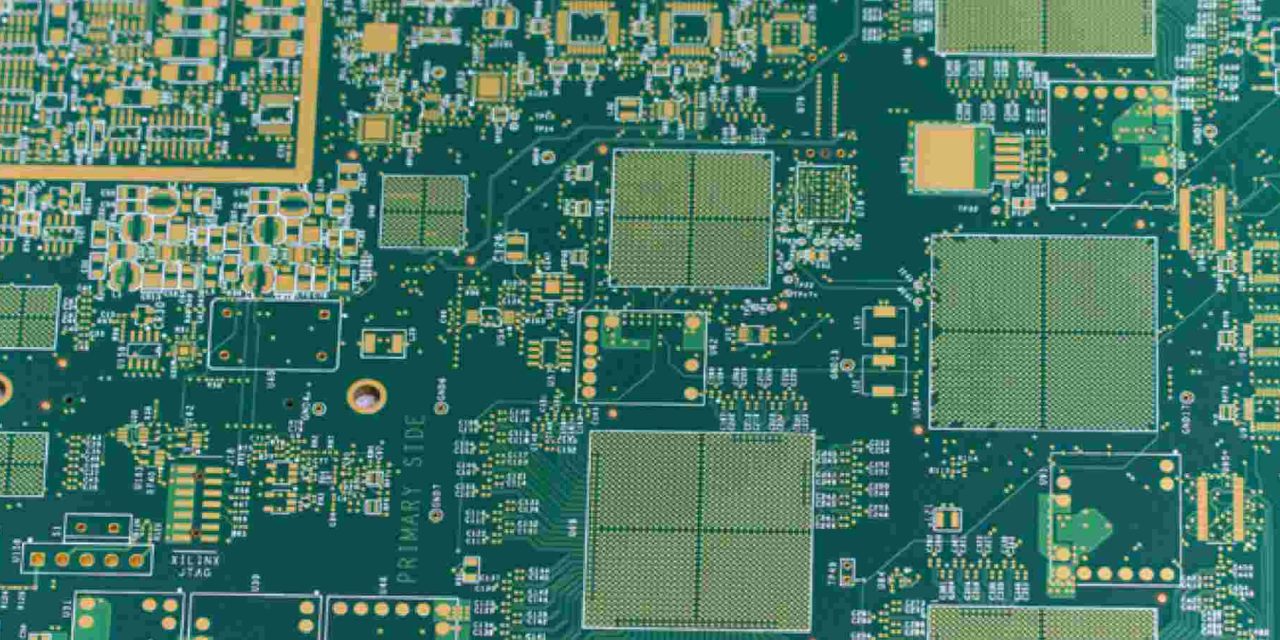

As digital systems move toward higher data rates, smaller form factors, and lower power consumption, the demand for High Speed PCB solutions continues to accelerate. From 10–112 Gbps SerDes links to DDR4/DDR5 memory buses and advanced communication modules, a High Speed PCB must deliver loss control, impedance stability, and electromagnetic reliability in increasingly complex environments....

As RF communication, IoT edge devices, automotive radar, and compact wireless modules continue to evolve, the Double Layer HF PCB has become a preferred architecture for delivering high-frequency stability, low insertion loss, and predictable electromagnetic performance. Although limited to two copper layers, a Double Layer HF PCB—when engineered correctly—can outperform many multilayer structures in signal...

1. Engineering Context As electronic systems push into higher frequencies—5G, mmWave sensing, radar, satellite communication, and precision instrumentation—the dissipation factor (Df) of PCB materials has become a primary performance determinant.A Low Dissipation Factor PCB minimizes dielectric loss, preserves signal integrity, and ensures stable operation at frequencies where traditional FR-4 rapidly degrades. Low Df PCBs bridge...