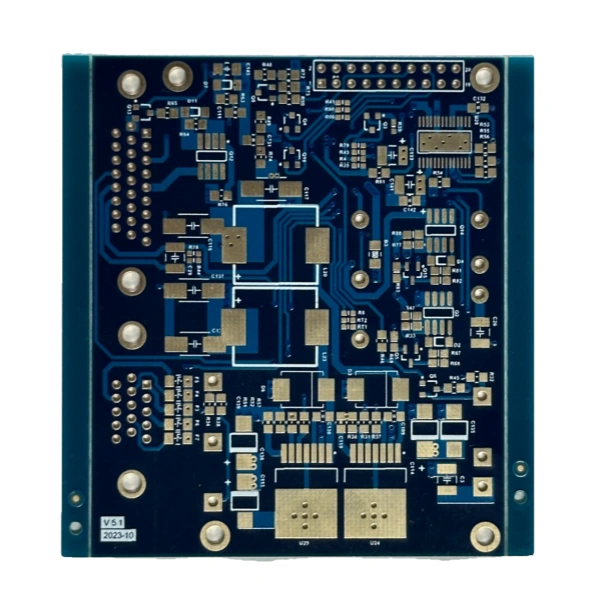

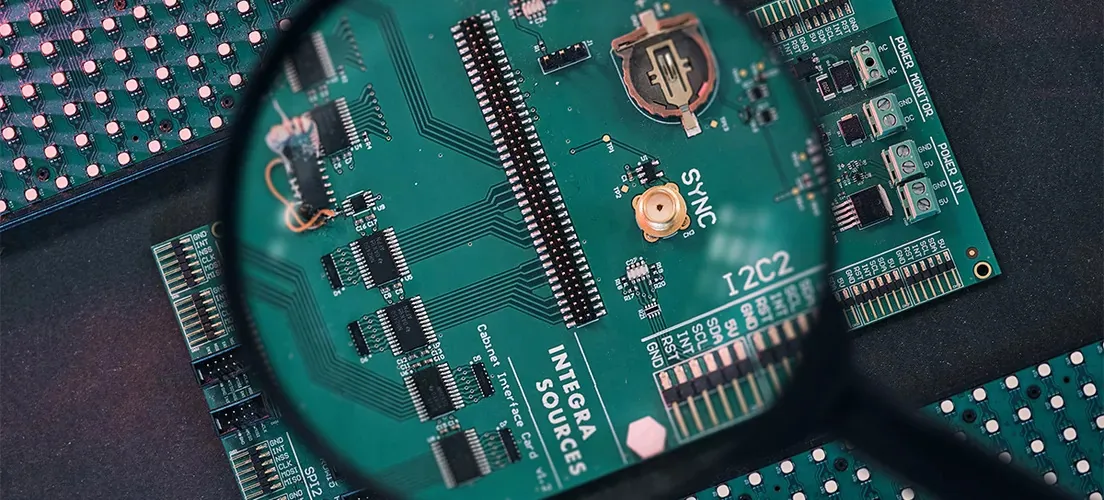

As electronic devices become smaller, faster, and more complex, traditional PCB technologies often reach their physical limits. HDI PCB (High Density Interconnect PCB) technology was developed to overcome these challenges by enabling higher wiring density, finer geometries, and improved electrical performance. A professionally manufactured HDI PCB is a key enabler for modern consumer electronics, communication...

HomeCategory

PCB Manufacturing Services | High-Quality PCB & PCBA - KKPCB

High Pin Count PCB: Enabling Dense Interconnection for Advanced Electronic and Semiconductor Systems

As electronic systems continue to integrate more functionality into smaller form factors, the number of signal, power, and ground connections continues to rise. The High Pin Count PCB is specifically engineered to manage thousands of interconnections while maintaining electrical integrity, mechanical reliability, and manufacturability. A professionally designed High Pin Count PCB is essential for modern...

In semiconductor production testing, accurate results depend not only on test equipment and software but also on the physical interface between the device under test (DUT) and the test system. The Test Socket PCB plays a critical role by providing a stable electrical and mechanical foundation for test sockets used in engineering validation and mass...

As 5G technology expands into millimeter-wave frequency bands, PCB design enters a new level of complexity. Operating at frequencies above 24 GHz, 5G mmWave PCB designs must manage extreme signal loss sensitivity, tight impedance tolerances, and strict manufacturing precision. A professionally engineered 5G mmWave PCB is essential for enabling high data rates, low latency, and...

As RF and microwave systems move toward higher frequencies and tighter performance margins, PCB substrate selection becomes a critical design decision. Duroid 6002 PCB, a PTFE-based laminate from Rogers, is widely used in applications that demand low dielectric loss, stable electrical performance, and high reliability. A professionally manufactured Duroid 6002 PCB provides consistent signal integrity...

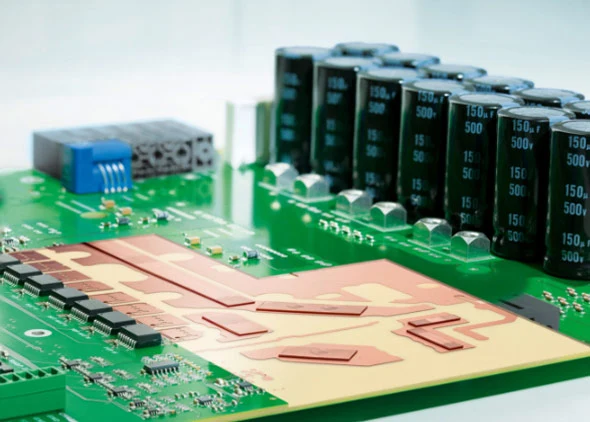

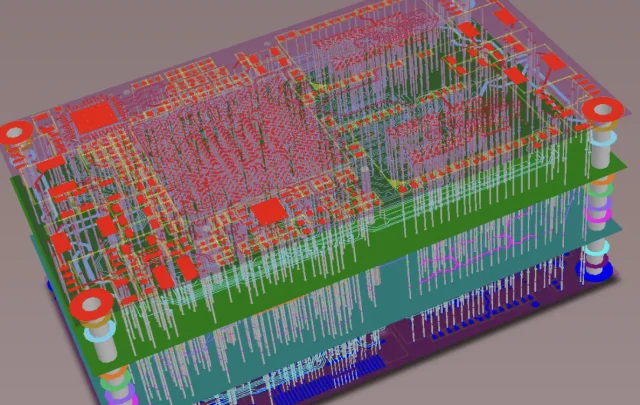

In high-volume semiconductor manufacturing, production testing must be fast, repeatable, and extremely reliable. At the center of this process is the Load Board PCB, a critical interface that connects automated test equipment (ATE) to the device under test (DUT). A well-designed Load Board PCB ensures that every device is evaluated under identical electrical conditions, enabling...

In semiconductor manufacturing, testing is not a single step—it is a continuous process that spans wafer probing, device validation, system-level testing, and mass production. At the core of this process lies the Semiconductor Test PCB, a specialized printed circuit board designed to deliver consistent electrical performance across every test stage. A well-designed Semiconductor Test PCB...

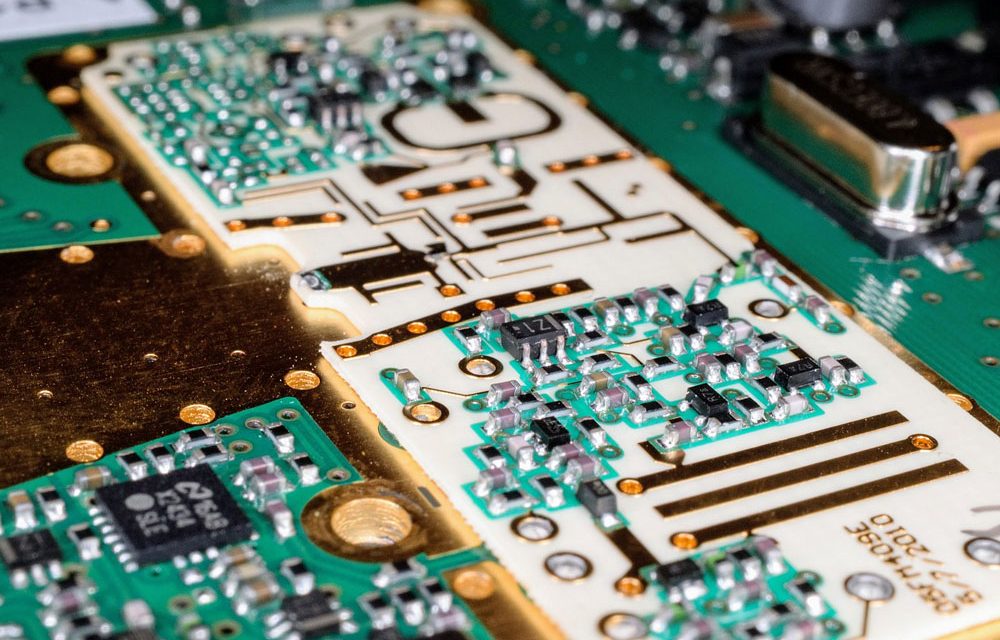

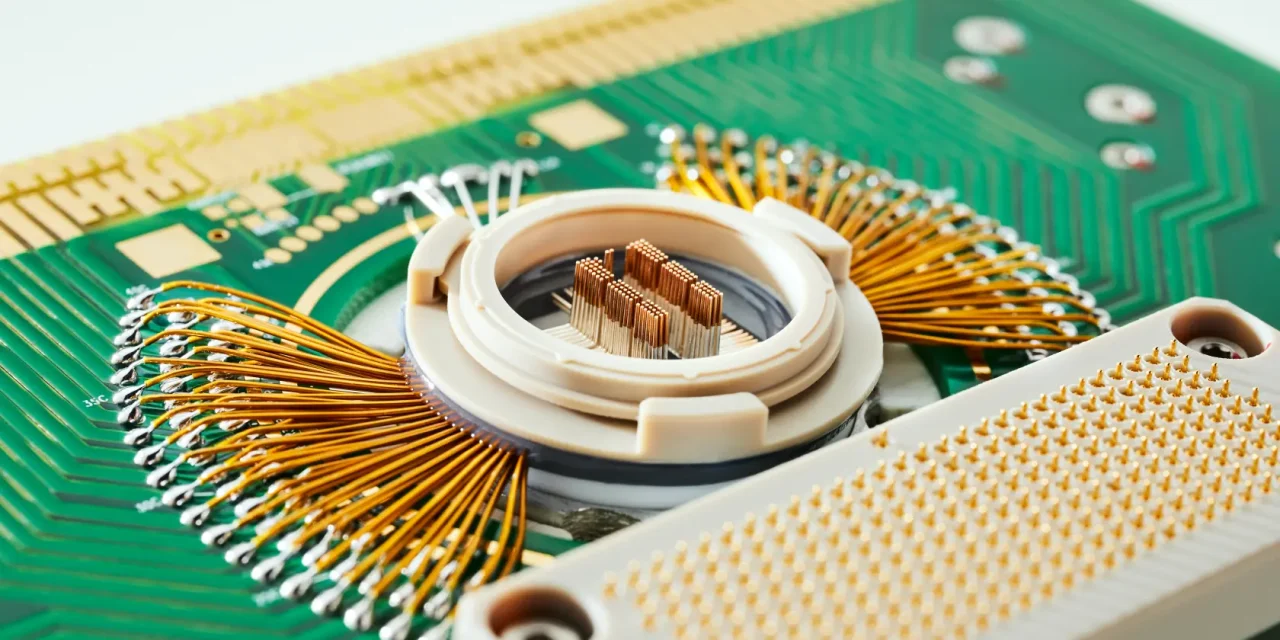

As semiconductor devices continue to scale down in size while increasing in performance, wafer-level testing demands extreme precision. At the heart of this process lies the Probe Card PCB, a critical platform that connects automated test equipment to microscopic probe needles touching individual die pads. A professionally manufactured Probe Card PCB directly determines probing accuracy,...

In modern semiconductor production, test accuracy must remain stable not only for one device, but across tens of thousands—or even millions—of test cycles. While ATE systems continue to advance in speed and precision, the ATE test PCB remains a decisive factor in determining whether test results are repeatable, reliable, and production-ready. A professionally engineered ATE...

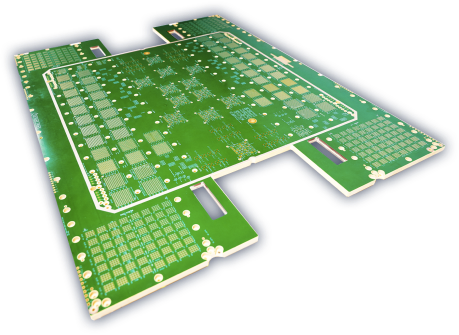

As semiconductor devices and electronic systems continue to increase in speed and complexity, test environments must deliver the same level of precision as the final product. The multilayer test PCB plays a critical role in ensuring accurate measurements, stable signal transmission, and repeatable test results across development and mass production. A well-designed multilayer test PCB...