A Rogers PCB is a high-performance printed circuit board manufactured using Rogers high-frequency laminate materials, which outperform standard FR-4 in RF, microwave, and high-frequency signal applications. Rogers PCB materials provide low dielectric loss, stable dielectric constant (Dk), and excellent controlled impedance, making them essential for modern high-speed electronics and wireless communication systems.

As technology evolves, applications like 5G, WiFi, GPS, satellite communication, radar systems, and IoT devices require PCBs that maintain signal integrity and low insertion loss at GHz frequencies. Rogers PCB delivers the required electrical performance while ensuring reliable manufacturing for multilayer, high-density, and high-speed designs.

What Is a Rogers PCB?

A Rogers PCB is fabricated using laminates such as RO4003C, RO4350B, RO3003, and other high-frequency materials. Unlike FR-4, Rogers laminates offer:

-

Low dielectric loss (low Df) for minimal signal attenuation

-

Stable dielectric constant (Dk) across frequency and temperature

-

Excellent controlled impedance for RF trace consistency

-

Reduced thermal expansion (CTE) for multilayer reliability

-

Superior mechanical and chemical stability for demanding environments

These properties make Rogers PCB ideal for RF trace routing, microwave circuits, antenna feed networks, and high-speed differential pairs.

Key Advantages of Rogers PCB

1. Low Dielectric Loss

High-frequency signals are highly sensitive to dielectric loss. Rogers PCB laminates have very low dissipation factor (Df), reducing insertion loss, improving signal strength, and enhancing overall signal integrity.

2. Stable Dielectric Constant

Rogers materials maintain a consistent Dk across a wide frequency range and varying environmental conditions. This ensures predictable impedance, which is crucial for RF, microwave, and high-speed PCB designs.

3. Controlled Impedance

Precise impedance control is essential for RF and high-speed PCB performance. Rogers PCB materials, combined with optimized stack-up design, allow engineers to achieve exact 50Ω, 75Ω, or differential impedance targets with minimal variation.

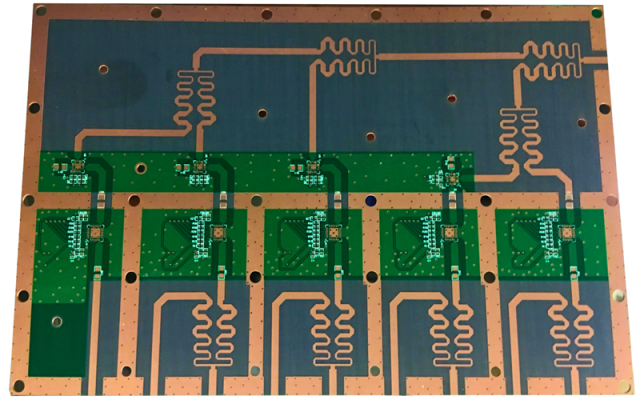

4. Superior Thermal and Mechanical Stability

Rogers PCB laminates have a low coefficient of thermal expansion (CTE) and high dimensional stability, which supports multilayer high-frequency PCB fabrication and ensures reliable via and trace performance in harsh environments.

5. Excellent High-Frequency Performance

Rogers PCBs support GHz-frequency signals with minimal signal degradation, making them ideal for:

-

RF communication modules (5G, WiFi, Bluetooth)

-

GPS and satellite systems

-

Radar and automotive ADAS modules

-

Microwave circuits and antennas

-

High-speed differential pair networks

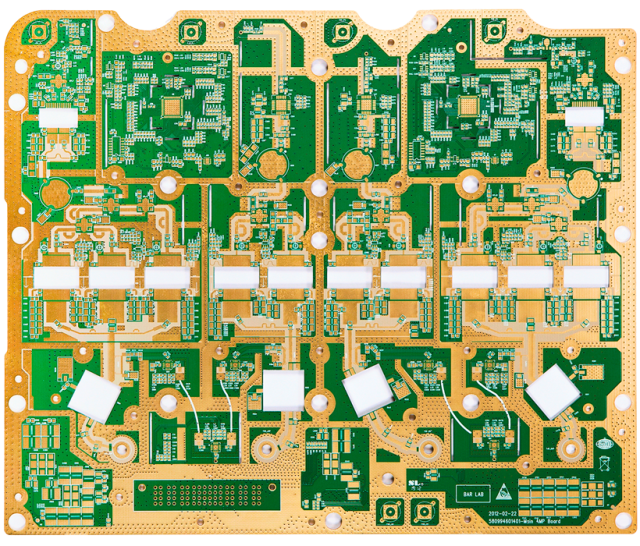

Applications of Rogers PCB

Rogers PCB is widely used across industries where low loss, controlled impedance, and high reliability are critical:

-

5G communication modules: base stations, mmWave devices, RF front-end modules

-

WiFi and Bluetooth: high-frequency PCB traces for routers and IoT devices

-

GPS and navigation modules: low-loss signal transmission for precise positioning

-

Radar systems: automotive radar, drone radar, and industrial sensors

-

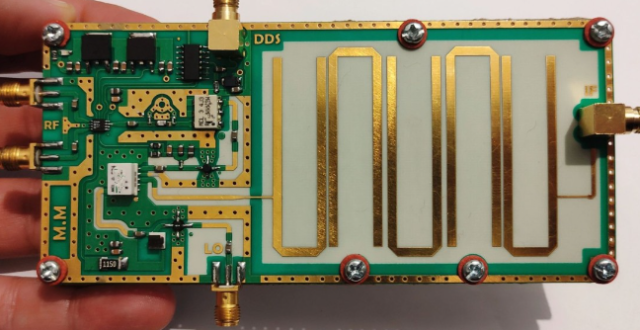

Microwave circuits: amplifiers, mixers, and filters

-

Antenna feed networks: maintaining impedance and reducing reflection

-

High-speed differential signal networks: PCIe, Ethernet, and SerDes boards

Rogers PCB Manufacturing Considerations

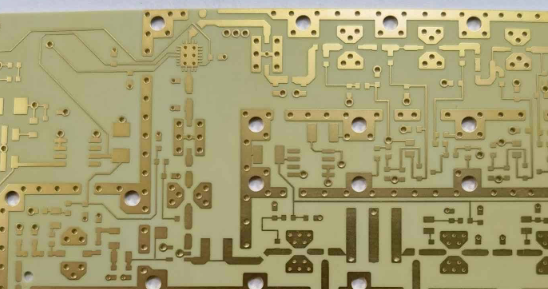

Manufacturing Rogers PCB requires precise process control due to the high-frequency requirements:

-

Trace width and spacing control to maintain impedance

-

Dielectric thickness consistency for stable Dk

-

Copper roughness optimization to reduce conductor loss

-

Multilayer lamination accuracy for stack-up reliability

-

Via and pad design to minimize reflection and insertion loss

-

Impedance testing to verify performance across the PCB

KKPCB ensures high-quality Rogers PCB fabrication, supporting both prototypes and mass production, with engineering assistance for stack-up planning, DFM, and controlled impedance verification.

Conclusion

A Rogers PCB is essential for high-frequency, RF, microwave, and high-speed applications where signal integrity, low loss, and controlled impedance are critical. By combining low-loss Rogers laminates, precise stack-up design, and strict manufacturing control, Rogers PCB provides stable, repeatable, and high-performance solutions for demanding electronics applications.

KKPCB delivers Rogers PCB manufacturing with advanced engineering support, multilayer capability, impedance control, and high reliability to meet the needs of 5G, RF, radar, GPS, microwave, and IoT systems.