A Low Loss PCB is a specialized printed circuit board engineered to minimize signal attenuation, dielectric loss, and crosstalk in high-speed, high-frequency, and RF electronic systems. With the rise of 5G, IoT, high-speed computing, and advanced semiconductor testing, ensuring signal integrity and reliable performance is more critical than ever.

Key Features of Low Loss PCBs

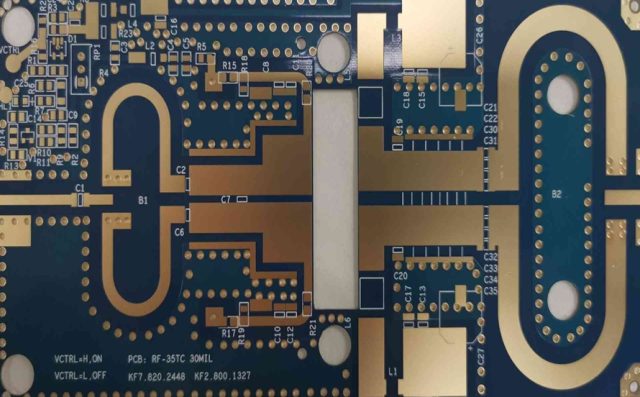

1. Low Dielectric Constant (Dk) and Dissipation Factor (Df)

Low loss PCBs use materials with low Dk/Df, which reduce signal distortion, insertion loss, and phase delay, ensuring high-frequency signals maintain integrity over long PCB traces.

2. Controlled Impedance Routing

Precise trace width, spacing, and layer stackup allow consistent impedance, critical for RF, microwave, and high-speed digital circuits. Controlled impedance improves signal fidelity and reduces reflections.

3. Microvia and HDI Technology

Using microvias, blind vias, and buried vias, low loss PCBs shorten signal paths, minimize parasitic inductance, and support high-density interconnects without sacrificing performance.

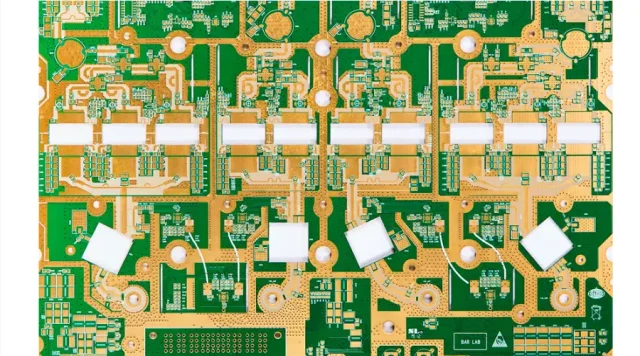

4. Multilayer Stackups

Advanced multilayer designs separate signal, power, and ground planes, improving EMI/EMC performance, crosstalk suppression, and power distribution, essential for high-speed electronics.

5. High Pin Count and Fine Pitch Support

Low loss PCBs support fine-pitch BGAs, QFNs, and CSP packages, enabling compact layouts and high-density designs for modern electronics.

Applications of Low Loss PCBs

Low loss PCBs are widely used in industries that require precision, high-speed, and high-frequency performance:

-

5G mmWave and RF communication modules

-

High-speed computing and networking equipment

-

IoT and wearable devices

-

Automotive radar and ADAS modules

-

Semiconductor IC test boards and ATE systems

-

Medical devices and compact industrial electronics

Manufacturing Considerations

Producing reliable low loss PCBs requires advanced fabrication processes and quality control:

-

Selection of low Dk/Df laminates for high-frequency performance

-

Controlled impedance design and verification

-

Microvia, blind, and buried via formation for HDI designs

-

Sequential lamination for multilayer boards

-

AOI, X-ray, and electrical testing to ensure quality and yield

By controlling materials and process precision, manufacturers ensure consistent signal integrity, low insertion loss, and long-term reliability.

Conclusion

Low Loss PCBs are essential for high-speed, high-frequency, and RF electronics. They provide minimal signal loss, stable impedance, and reliable performance, supporting applications from 5G and IoT to semiconductor testing and automotive radar systems. Partnering with experienced PCB manufacturers ensures optimized design, superior electrical performance, and high manufacturing yield.