What Is a Rogers PCB?

A Rogers PCB is a printed circuit board that uses Rogers high-frequency laminates, such as RO4003C, RO4350B, and Duroid series, designed for low dielectric loss, precise impedance control, and high-frequency signal transmission. Rogers PCBs are essential in 5G communications, RF/microwave modules, high-speed computing, and aerospace electronics.

Why Rogers PCB Technology Matters

As electronic systems move to higher frequencies, standard FR-4 laminates are often insufficient. Rogers PCBs address critical challenges including:

-

Signal loss and dielectric heating at GHz frequencies

-

Impedance mismatch and signal reflections

-

Crosstalk and EMI in high-speed circuits

-

Stable phase and timing for RF and microwave systems

-

Compact routing for high-density designs

They ensure reliable performance for high-frequency and high-speed applications.

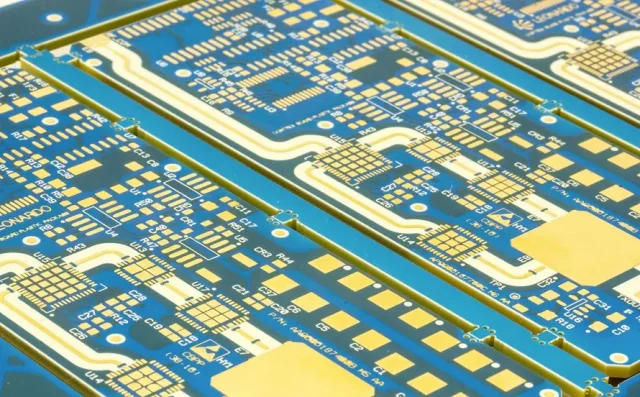

Key Features of Rogers PCBs

High-quality Rogers PCBs typically include:

-

Low-loss dielectric laminates for minimal signal attenuation

-

Controlled impedance traces for high-speed or RF signals

-

Multilayer HDI and microvia capability for dense layouts

-

Fine line and spacing for compact, high-density routing

-

Thermal and mechanical stability for harsh environments

These features make Rogers PCBs ideal for RF modules, 5G mmWave devices, and aerospace systems.

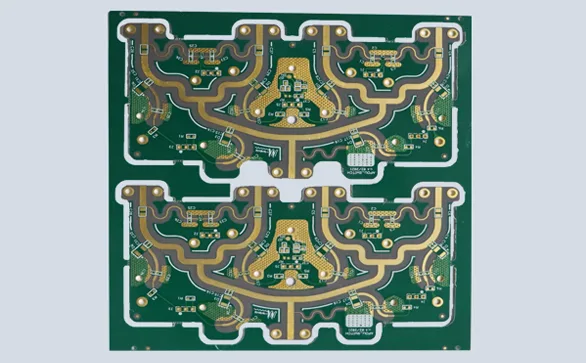

Design Considerations for Rogers PCBs

Designing Rogers PCBs requires attention to:

-

Precise trace width, spacing, and impedance matching

-

Minimizing vias and discontinuities in high-speed lines

-

Layer stackup optimization for signal integrity and EMI control

-

Differential pair routing for high-speed interfaces

-

Thermal management for high-frequency power handling

Proper design ensures consistent high-frequency performance and signal integrity.

Materials for Rogers PCBs

Rogers PCB materials include:

-

RO4003C – low-loss, stable dielectric for RF and microwave

-

RO4350B – high thermal conductivity for power and RF applications

-

Duroid 5880 / 6010 – extremely low dielectric loss for mmWave and microwave circuits

-

Hybrid laminates for mixed-signal integration with FR-4 cores

Choosing the right Rogers laminate ensures minimal insertion loss and high signal fidelity.

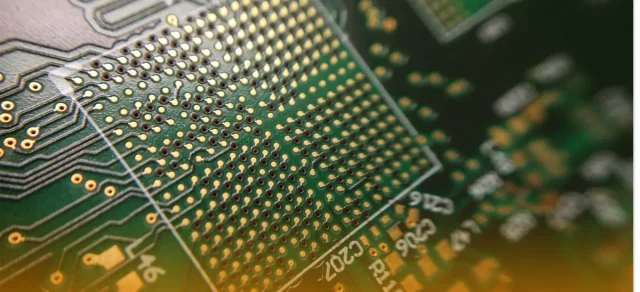

Manufacturing Capabilities for Rogers PCBs

Fabricating Rogers PCBs requires:

-

High-precision etching and imaging

-

Laser-drilled microvias and HDI multilayer lamination

-

Controlled impedance verification (TDR)

-

Automated optical inspection (AOI) and electrical testing

-

Thermal and mechanical reliability testing

Professional manufacturing guarantees consistent RF and high-speed PCB performance.

Assembly Considerations for Rogers PCBs

Assembly of Rogers PCBs includes:

-

Fine-pitch IC and RF component placement

-

Controlled soldering profiles to avoid trace damage

-

Shielding and grounding for EMI reduction

-

Functional testing for RF signal quality and insertion loss

-

ESD-safe handling for sensitive high-frequency components

Correct assembly preserves signal integrity and long-term reliability.

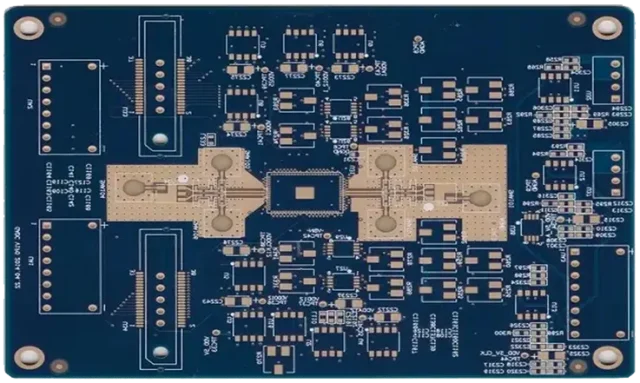

Applications of Rogers PCBs

Rogers PCBs are widely used in:

-

5G communication modules and mmWave antennas

-

RF transceivers and wireless communication systems

-

High-speed computing and data center boards

-

Semiconductor test boards and ATE systems

-

Automotive radar and ADAS electronics

-

Aerospace and defense high-frequency systems

They are essential wherever high-frequency, low-loss, and controlled impedance performance is required.

Why Choose a Professional Rogers PCB Manufacturer

A professional Rogers PCB manufacturer provides:

-

Expertise in high-frequency laminate selection and controlled impedance

-

Stable manufacturing for multilayer and HDI Rogers boards

-

Prototype, small batch, and mass production support

-

Advanced RF testing (TDR, VNA) and inspection

-

One-stop PCB fabrication and assembly services

The right partner ensures high-frequency performance, signal integrity, and reliable system operation.