What Is a Power Integrity PCB?

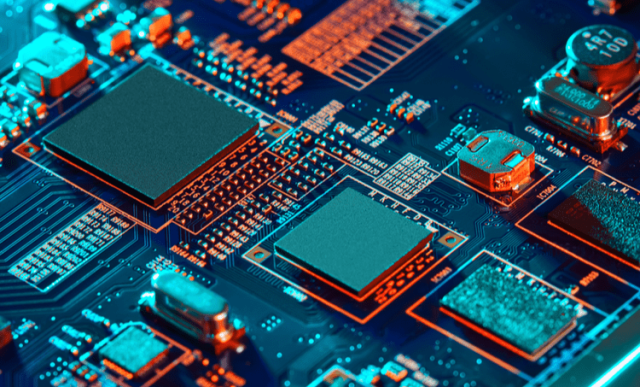

A Power Integrity (PI) PCB is a specialized printed circuit board designed to maintain stable voltage, minimize power noise, and ensure consistent current delivery across all components in high-speed, high-frequency, and high-density electronic systems.

In modern electronics, poor power integrity can lead to signal errors, timing instability, and even component malfunction, making Power Integrity PCB design essential for applications ranging from 5G communication modules and IoT devices to high-speed computing, automotive electronics, and industrial control systems.

Why Power Integrity Matters

High-speed and high-density PCB designs are extremely sensitive to voltage drops, current fluctuations, and power noise. Issues with power integrity can result in:

-

Increased jitter and timing errors in high-speed digital circuits

-

Signal integrity degradation in RF and high-frequency systems

-

Electromagnetic interference (EMI) due to unstable power planes

-

Reduced overall system reliability and performance

By carefully designing the power distribution network (PDN), a Power Integrity PCB ensures clean, stable, and consistent voltage delivery to all critical components.

Key Design Principles for Power Integrity PCBs

1. Optimized Power Plane and Ground Plane Design

-

Use solid copper power planes and multiple ground planes to reduce voltage drop and minimize current loop impedance.

-

Ensure proper power-to-ground layer stacking for optimal high-frequency performance.

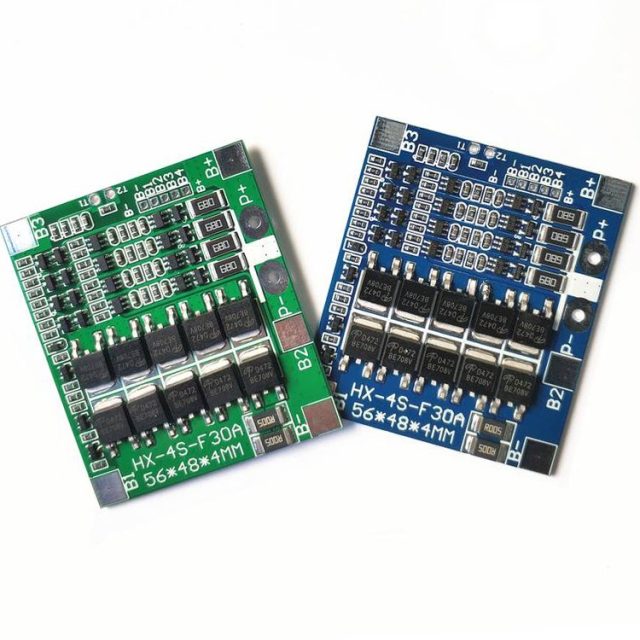

2. Decoupling and Bypass Capacitor Strategy

-

Strategically place decoupling capacitors close to ICs to reduce power noise and transient voltage fluctuations.

-

Ensure correct capacitor values and placement to support high-speed and high-frequency devices.

3. Controlled Impedance and Signal-Plane Coordination

-

Design signal layers and power planes together to maintain consistent impedance, reduce crosstalk, and prevent ground bounce.

-

Use via stitching and power vias to enhance current distribution and thermal management.

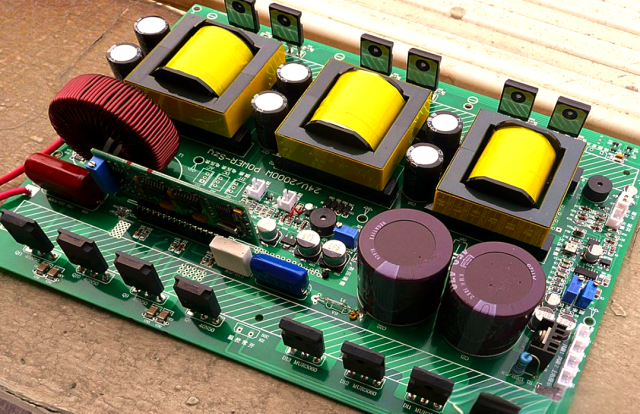

4. Advanced PCB Materials for High-Speed Applications

-

Utilize low Dk / low Df laminates for RF, high-speed digital, and 5G applications to reduce power loss and maintain signal integrity.

-

Consider high Tg FR4 or metal-core substrates for power electronics to handle higher current densities and heat dissipation.

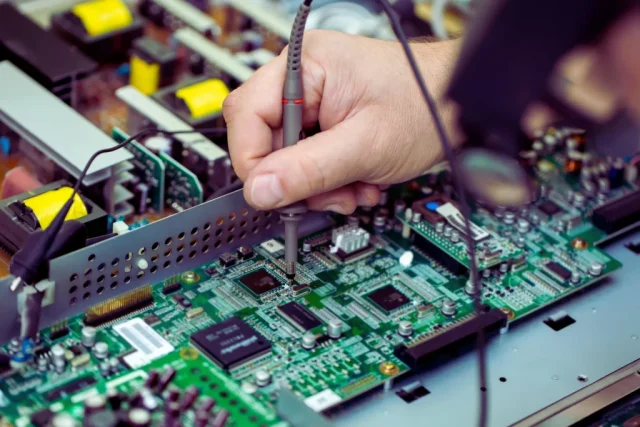

5. Simulation and Validation

-

Perform Power Integrity simulation to predict voltage drops, noise, and IR drop across the PCB.

-

Validate designs with electrical testing, thermal analysis, and high-speed signal testing to ensure reliability.

Applications of Power Integrity PCBs

Power Integrity PCBs are widely used in applications where stable voltage and reliable current distribution are critical:

-

High-speed computing and data center servers

-

5G base stations and RF modules

-

Automotive electronics, EV power control, and ADAS systems

-

IoT devices, wearable electronics, and high-density consumer products

-

Industrial power electronics and motor controllers

-

Semiconductor testing boards, ATE, and load boards

KKPCB Power Integrity PCB Manufacturing Capabilities

KKPCB offers end-to-end Power Integrity PCB solutions, including:

-

Controlled impedance and optimized power plane stack-up design

-

Multilayer PCB fabrication for high-speed and high-density applications

-

Advanced PCB materials selection for high-frequency and high-power circuits

-

Precision decoupling, via, and thermal design implementation

-

Comprehensive electrical and thermal testing for production-ready PCBs

With extensive experience, KKPCB ensures each Power Integrity PCB meets strict electrical, thermal, and reliability standards, from prototype to mass production.

Conclusion

A Power Integrity PCB is critical for high-speed, high-frequency, and high-power electronics. By carefully designing power planes, controlling voltage drops, minimizing noise, and using advanced materials, Power Integrity PCBs ensure stable system operation, improved reliability, and long-term performance.

For any project requiring high-performance voltage stability and reliable power delivery, KKPCB is your trusted Power Integrity PCB manufacturer and engineering partner.