Megtron PCB: A Low-Loss Solution for High-Speed Digital and Advanced Electronics

As electronics continue to evolve toward higher data rates, lower latency, and greater integration, PCB materials play a critical role in maintaining signal quality. In high-speed applications such as data centers, servers, 5G infrastructure, and high-performance networking equipment, signal loss and impedance instability can significantly impact overall system performance.

That’s why many engineers select Megtron PCB materials—a well-known low-loss solution designed to improve signal integrity and reliability for advanced high-speed designs.

In this article, we’ll explain what Megtron PCB is, its main benefits, typical applications, and important manufacturing considerations.

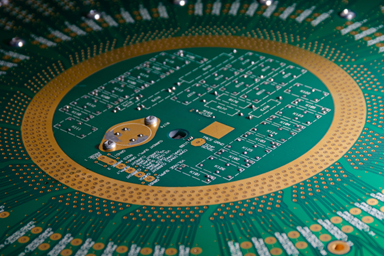

What Is a Megtron PCB?

Megtron PCB refers to printed circuit boards manufactured using Panasonic Megtron series laminate materials, which are designed for high-speed digital transmission and low-loss performance.

Megtron materials are widely used in applications requiring:

-

Low dielectric loss (low Df)

-

Stable dielectric constant (Dk)

-

Excellent thermal reliability

-

High-speed signal integrity support

Common Megtron material families may include options like Megtron 6, which is popular for high-speed networking and data communication designs.

Why Megtron PCB Matters in High-Speed Design

In high-speed PCB designs, signals can be easily degraded by:

-

Dielectric loss

-

Conductor loss

-

Crosstalk and noise

-

Impedance mismatch

-

Timing skew and jitter

Megtron PCB materials help reduce these risks by offering electrical stability and low-loss performance, supporting reliable transmission for modern high-speed interfaces.

Key Benefits of Megtron PCB

1. Low Dielectric Loss for Cleaner Signals

Megtron PCB materials are known for low Df performance, which helps reduce signal attenuation.

Benefits include:

-

Improved insertion loss performance

-

Longer transmission distance at high data rates

-

Cleaner eye diagrams for high-speed signals

-

Reduced need for additional signal conditioning

This is critical for multi-gigabit designs.

2. Stable Dielectric Constant (Dk) for Impedance Control

Megtron materials provide stable Dk characteristics, which supports:

-

Accurate controlled impedance routing

-

Stable propagation delay

-

Better timing consistency across channels

This helps engineers achieve reliable high-speed performance in complex designs.

3. Excellent Thermal Reliability

High-speed systems often operate under heavy workloads and higher temperatures. Megtron PCB materials offer good thermal stability, supporting:

-

High layer count designs

-

Dense component placement

-

Reliable assembly processes such as reflow soldering

4. Suitable for High Layer Count and Advanced Stack-Ups

Many high-speed digital designs require complex stack-ups with multiple signal layers, power planes, and ground planes.

Megtron PCB is commonly used in:

-

High layer count boards

-

Backplanes and midplanes

-

High-density high-speed routing structures

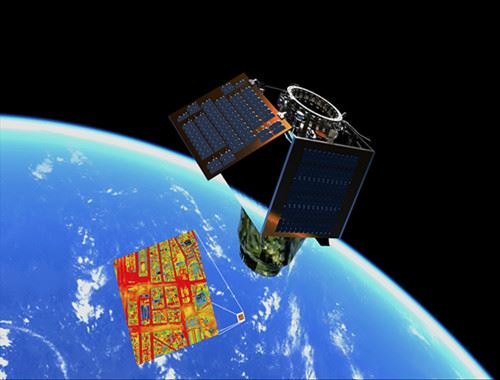

Typical Applications of Megtron PCB

Megtron PCB materials are widely used in high-speed and high-reliability industries.

Data Centers and Servers

Megtron PCB is often used in:

-

Server motherboards

-

High-speed backplanes

-

Storage systems

-

AI computing platforms

Low loss helps support high data throughput and stable performance.

Networking and Telecom Equipment

Megtron PCB is common in:

-

Network switches

-

Routers

-

Optical communication equipment

-

5G base station systems

Stable signal performance is critical for reliable communication infrastructure.

High-Speed Backplanes and Interconnects

Backplanes require low loss materials to support long signal paths and high-speed transmission. Megtron PCB helps reduce attenuation and maintain signal quality across complex systems.

High-Reliability Industrial Electronics

Megtron PCB materials are also used in industrial systems requiring stable operation, such as:

-

High-speed control systems

-

Automation equipment

-

Industrial communication modules

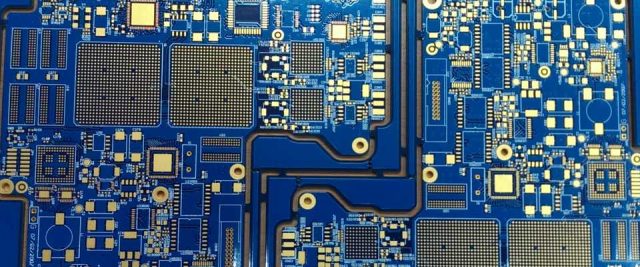

Megtron PCB vs Standard FR4

FR4 remains a mainstream material, but it may not meet performance needs for advanced high-speed designs.

| Feature | Standard FR4 | Megtron PCB |

|---|---|---|

| Dielectric Loss (Df) | Higher | Lower |

| High-Speed Performance | Limited | Excellent |

| Dk Stability | Moderate | Better |

| Controlled Impedance | More difficult | More consistent |

| Typical Use | General electronics | High-speed digital systems |

For designs with high-speed interfaces, Megtron PCB provides better signal integrity and performance margin.

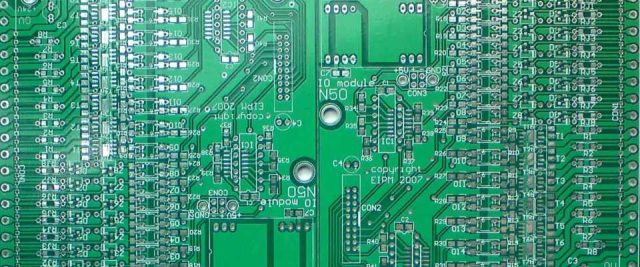

Manufacturing Considerations for Megtron PCB

To achieve stable electrical performance, Megtron PCB manufacturing requires strict control of process details, including:

Stack-Up Design and Impedance Verification

Controlled impedance is essential for high-speed designs. Manufacturers typically support:

-

Stack-up optimization

-

Dielectric thickness control

-

Impedance testing and reporting

Copper Roughness and Loss Control

In high-speed designs, copper surface roughness can impact conductor loss. Optimized copper foil selection helps reduce insertion loss and improve signal quality.

High Layer Count Lamination Control

Megtron PCB is often used in multi-layer designs. Reliable lamination and registration control help prevent:

-

Delamination

-

Misalignment

-

Warpage

Quality Inspection and Reliability Testing

A professional manufacturer may apply:

-

AOI inspection

-

Electrical testing

-

Impedance testing

-

Microsection analysis (as needed)

This helps ensure stable quality for high-speed applications.

How to Choose the Right Megtron PCB Supplier

When selecting a Megtron PCB supplier, it’s recommended to evaluate:

-

Experience with Panasonic Megtron materials

-

Capability for high layer count production

-

Controlled impedance and insertion loss control

-

Engineering support for DFM and stack-up review

-

Stable quality and lead time performance

A reliable supplier can help shorten development cycles and reduce risk in high-speed projects.

Conclusion

Megtron PCB is an excellent choice for high-speed digital and advanced electronics requiring low loss, stable Dk, controlled impedance performance, and strong reliability. It is widely used in data centers, networking equipment, telecom systems, and high-speed backplanes, helping engineers achieve cleaner signals and better overall system performance.

If your project requires stable high-speed signal transmission beyond standard FR4, Megtron PCB materials are a strong solution worth considering.