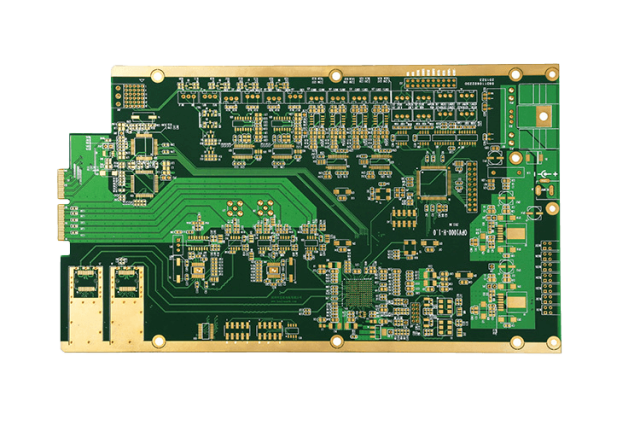

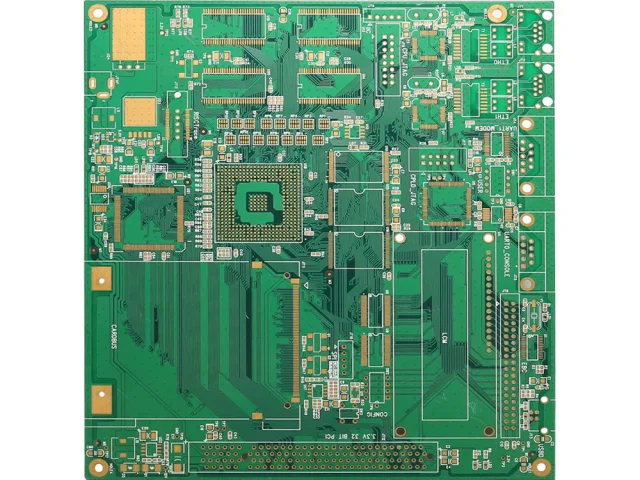

A High Reliability PCB is a printed circuit board specifically designed to maintain exceptional electrical and mechanical performance under demanding conditions. Unlike standard PCBs, high reliability PCBs are engineered to withstand harsh environments, high temperatures, mechanical stress, and prolonged operational cycles, making them indispensable for mission-critical and high-performance electronic systems.

These PCBs are widely used in aerospace, defense, automotive, medical devices, industrial automation, and high-speed computing, where failure is not an option and system reliability is paramount.

Key Features of High Reliability PCBs

1. Advanced Material Selection

High reliability PCBs use high-Tg laminates, low CTE materials, and flame-retardant substrates to withstand extreme temperatures and reduce mechanical stress.

2. Robust Multilayer and HDI Design

High reliability PCBs often incorporate multilayer stackups and HDI routing with microvias and controlled impedance to ensure signal integrity and high-density interconnects even in complex designs.

3. Thermal and Mechanical Stability

These PCBs are engineered to minimize warpage, delamination, and thermal expansion, ensuring consistent performance in high-temperature environments or under continuous mechanical stress.

4. Controlled Impedance and Signal Integrity

For high-speed, RF, or mixed-signal circuits, precise controlled impedance routing maintains signal fidelity and reduces signal loss, crosstalk, and reflection.

5. Stringent Testing and Quality Assurance

High reliability PCBs undergo automated optical inspection (AOI), X-ray testing, thermal cycling, and electrical testing to guarantee long-term durability and reliability.

Applications of High Reliability PCBs

High reliability PCBs are essential in:

-

Automotive electronics and ADAS modules

-

Aerospace and defense control systems

-

Medical imaging, monitoring, and diagnostic devices

-

Industrial automation and process control electronics

-

High-speed networking and server boards

-

Semiconductor test boards and high-frequency RF modules

These applications require failure-free operation, consistent signal integrity, and long-term reliability under demanding environmental and operational conditions.

Manufacturing Requirements for High Reliability PCBs

Producing high-quality high reliability PCBs involves:

-

Advanced laminates and high-Tg materials

-

Precision multilayer and HDI fabrication

-

Microvia formation and controlled impedance routing

-

Thermal management and copper plane optimization

-

Rigorous quality control, including AOI, X-ray, and functional testing

Strict process control ensures high yield, durability, and performance consistency in critical applications.

Why High Reliability PCB Quality Matters

Poor-quality PCBs in critical systems can lead to:

-

Premature component or system failure

-

Electrical signal degradation or EMI issues

-

Reduced safety and operational efficiency

-

Increased maintenance and replacement costs

Professionally manufactured High Reliability PCBs provide robust, durable, and stable performance, ensuring that critical systems operate reliably over extended lifespans.

Conclusion

The High Reliability PCB is a cornerstone for mission-critical electronics. Through advanced materials, multilayer HDI design, controlled impedance routing, and rigorous manufacturing standards, high reliability PCBs ensure long-term durability, thermal stability, and electrical integrity.

Partnering with an experienced high reliability PCB manufacturer guarantees consistent performance, reduced failure rates, and dependable operation in automotive, aerospace, medical, and industrial systems.