Introduction

5G is not just an upgrade from 4G—it represents a technological leap forward in global connectivity. With ultra-high speed, wide bandwidth, and expanded frequency ranges such as sub-6 GHz and millimeter wave (mmWave), 5G transforms how devices communicate.

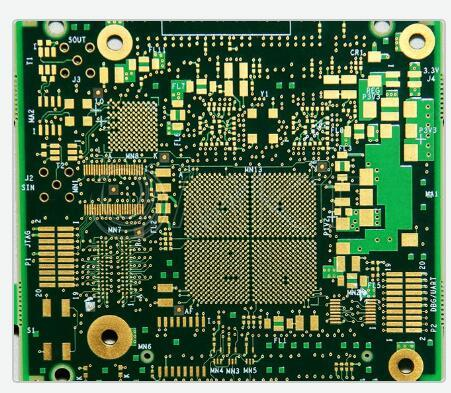

At the core of this revolution lies one critical component — the Printed Circuit Board (PCB). A 5G PCB must handle higher frequencies, maintain signal integrity, and ensure thermal stability — all within tighter tolerances than ever before. It’s more than a circuit carrier; it’s the foundation that makes 5G performance possible.

Key 5G PCB Drivers & Applications

5G operates in two main frequency bands:

-

Sub-6 GHz provides broad coverage and strong penetration, making it ideal for nationwide and rural networks.

-

mmWave delivers ultra-fast data rates and minimal latency but requires precise line control and advanced materials due to its limited range and higher signal loss.

For PCB designers, these frequencies introduce stricter requirements on impedance control, dielectric stability, and signal integrity. Advanced laminates such as Rogers, PTFE, or LCP are preferred for consistent electrical performance at these frequencies.

Cross-Industry Applications

The demand for 5G PCBs extends across multiple high-tech sectors:

-

Mobile & Consumer Electronics: Compact multilayer PCBs supporting high-speed data transfer.

-

Base Stations: Large, thermally stable boards ensuring consistent power handling.

-

IoT Devices: Ultra-efficient boards designed for low-power, continuous connectivity.

-

Automotive & Smart Mobility: Reliable PCBs used in V2X communication, sensors, and radar systems.

-

AR/VR Systems: Ultra-low-latency boards enabling real-time immersive experiences.

As 5G expands globally, manufacturers capable of high-frequency material processing, fine-line etching, and multilayer stacking are poised to lead the market.

Material Selection & Stack-Up Optimization

5G PCBs operate in an environment where precision is everything. The choice of substrate directly affects performance, loss, and heat stability.

High-frequency materials such as Rogers RO4350B, Taconic RF-35, or PTFE composites offer low dielectric loss and stable characteristics, ensuring reliable signal propagation up to 77 GHz.

FR-4 vs. High-Frequency Laminates

While FR-4 remains a cost-effective solution for sub-6 GHz applications, it falls short at mmWave frequencies. High-performance laminates—though more expensive—deliver the low Dk, low Df, and thermal stability essential for 5G applications.

In some cases, hybrid stack-ups combine FR-4 with high-frequency cores to balance performance and cost.

Signal Integrity & Impedance Control

At high data rates, even minute imperfections can cause major performance degradation. Maintaining signal integrity is therefore a top design priority.

Engineers achieve this through controlled impedance design, which involves precisely defining trace width, dielectric height, and copper thickness.

Microstrip and stripline configurations help maintain consistent impedance, while solid grounding, short return paths, and strategic shielding minimize interference and crosstalk.

Collaborating with PCB manufacturers early in the design phase ensures that impedance targets and fabrication limits are fully aligned — reducing risk and ensuring first-pass success.

Antenna & RF Integration

In 5G systems, the antenna and PCB are inseparable. Phased-array and beamforming antennas require exact coordination with the PCB layout to achieve superior radiation performance.

Proper antenna placement, short RF paths, and clean grounding are vital for minimizing signal loss.

For compact devices such as IoT sensors or wearables, designers must carefully isolate the RF section, apply shielding where needed, and maintain adequate clearance from metal components to ensure stable signal transmission.

EMI/EMC & Thermal Management

As frequency increases, electromagnetic interference (EMI) becomes a significant design challenge. Effective EMI mitigation includes:

-

Solid ground planes and shielding structures

-

Careful routing to minimize coupling between high-speed and RF signals

-

Segregation of analog, digital, and RF domains

5G systems also generate substantial heat. Designers must employ thermal vias, heat-conductive materials, and optimized component layouts to maintain performance and longevity.

Before production, each board undergoes thermal cycling, vibration, and mechanical stress tests to ensure reliability under real-world conditions.

Manufacturing Precision & Long-Term Reliability

5G PCB fabrication requires tight process control, fine-line capability, and high-density interconnect (HDI) techniques such as semi-additive processing (SAP).

Close collaboration between designers and manufacturers ensures the final board meets both performance and manufacturability targets.

To guarantee long-term reliability, 5G boards must withstand thermal stress, mechanical vibration, and environmental aging. KKPCB employs rigorous quality control and advanced testing to ensure durability across the full product lifecycle.

Conclusion: Building the Future with Precision

The transition to 5G isn’t just about faster communication—it’s a redefinition of connectivity itself. Every trace, layer, and material choice matters.

At KKPCB, we specialize in high-frequency PCB design and manufacturing, combining technical expertise with precision engineering to support your next-generation 5G projects.

From material selection to RF layout optimization and mass production, our team ensures that every board delivers unmatched signal integrity, thermal reliability, and cost efficiency.

Let’s engineer the future of connectivity — together.