A Low Loss PCB is a specialized printed circuit board designed to reduce dielectric loss, insertion loss, and signal distortion in high-speed and high-frequency electronic systems. As modern electronics such as 5G communication systems, RF front-end modules, high-speed data transmission, and semiconductor test equipment operate at ever-increasing frequencies, signal integrity becomes a critical design challenge.

Low Loss PCBs address this challenge by combining advanced low-loss materials, precise controlled impedance design, optimized multilayer stackups, and high-precision manufacturing processes to deliver reliable electrical performance.

Key Characteristics of Low Loss PCBs

1. Low Dielectric Constant (Dk) and Low Dissipation Factor (Df)

Low Loss PCBs utilize laminates with low Dk and ultra-low Df, which significantly reduce signal delay, phase distortion, and energy dissipation. This is essential for RF, microwave, mmWave, and high-speed digital applications.

2. Controlled Impedance Design

Accurate control of trace width, spacing, dielectric thickness, and reference planes ensures stable impedance for differential pairs and single-ended signals. Controlled impedance is critical for high-speed PCB, RF PCB, and 5G PCB designs.

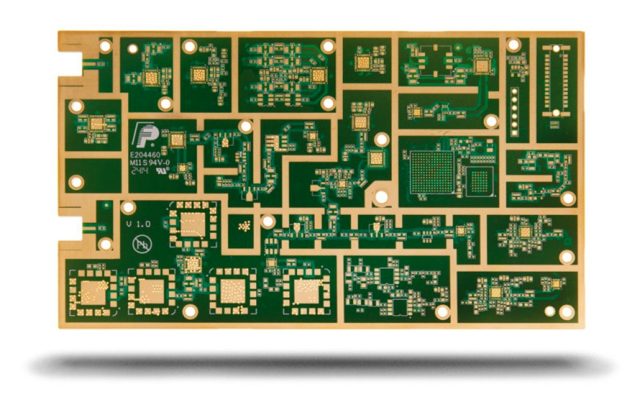

3. Multilayer and High-Density Structures

Low Loss PCBs often采用 multilayer stackups, combining signal layers with dedicated power and ground planes to improve signal integrity, EMI control, and power distribution.

4. Reduced Signal Attenuation and Crosstalk

By minimizing dielectric loss and optimizing routing, Low Loss PCBs reduce crosstalk, jitter, and insertion loss, enabling clean signal transmission over longer distances and higher data rates.

5. Compatibility with Advanced PCB Technologies

Low Loss PCB designs are fully compatible with HDI PCB, microvia PCB, blind and buried via PCB, and fine-pitch component layouts, supporting complex and compact electronic designs.

Common Materials Used in Low Loss PCBs

To achieve superior electrical performance, Low Loss PCBs commonly use advanced materials such as:

-

Rogers RO4003C / RO4350B

-

PTFE-based laminates

-

Taconic RF series

-

Isola low-loss materials

-

Hybrid stackups combining FR-4 and low-loss laminates

These materials provide stable electrical properties across wide frequency and temperature ranges.

Applications of Low Loss PCBs

Low Loss PCBs are widely used in applications where high-frequency stability and signal integrity are critical:

-

5G and mmWave communication modules

-

RF and microwave front-end circuits

-

High-speed networking and data center equipment

-

Automotive radar and ADAS systems

-

IoT devices and wireless modules

-

Semiconductor IC testing, ATE, and probe card systems

Manufacturing Considerations for Low Loss PCBs

Producing a reliable Low Loss PCB requires strict process control and advanced fabrication capabilities, including:

-

Precise impedance calculation and stackup simulation

-

Tight control of etching, lamination, and dielectric thickness

-

High-quality via plating and microvia processing

-

Advanced AOI, impedance testing, and electrical testing

-

Clean manufacturing environments to prevent contamination affecting signal loss

These steps ensure consistent performance from prototype to mass production.

Conclusion

A Low Loss PCB is essential for modern electronics that demand high-speed data transmission, high-frequency operation, and excellent signal integrity. By combining low-loss materials, controlled impedance design, multilayer structures, and precision manufacturing, Low Loss PCBs provide a reliable foundation for RF, 5G, IoT, automotive, and semiconductor testing applications.

For engineers and system designers, choosing the right Low Loss PCB supplier is critical to achieving stable performance and long-term product reliability.