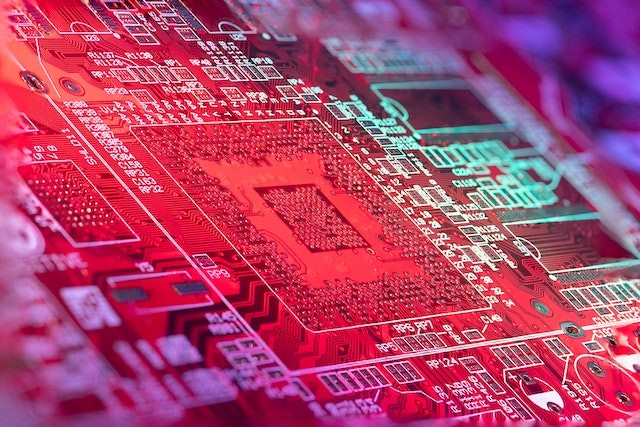

A High Reliability PCB is a printed circuit board designed to maintain consistent performance, stability, and durability under harsh environmental conditions and high operational demands. As modern electronics in aerospace, automotive, industrial, and medical systems operate under extreme temperature, vibration, and mechanical stress, high reliability PCB technology becomes essential to prevent failures and ensure product longevity.

Key Features of High Reliability PCBs

1. Robust Material Selection

High reliability PCBs utilize high Tg (glass transition), low CTE (coefficient of thermal expansion), and high-quality laminates to withstand thermal cycles, mechanical stress, and environmental exposure.

2. Advanced Multilayer Stackups

By employing multilayer designs, these PCBs provide optimized power distribution, signal integrity, and EMI suppression, essential for high-speed digital, RF, and aerospace electronics.

3. Controlled Impedance and Signal Integrity

Precision trace width, spacing, and dielectric thickness ensure stable impedance, reducing reflections and signal loss in high-speed and high-frequency circuits.

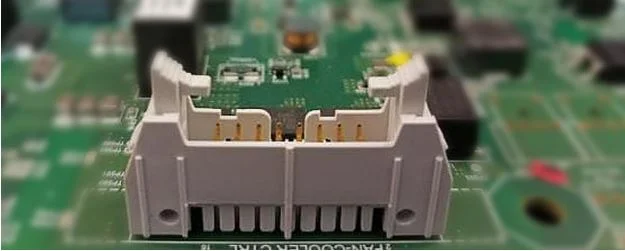

4. Thermal Management Features

High reliability PCBs often include thermal vias, metal cores, heat sinks, and copper planes to manage heat effectively, preventing thermal degradation in critical applications.

5. Vibration and Mechanical Resistance

Through reinforced substrates, plated through-holes, and advanced lamination, these PCBs endure vibration, shock, and mechanical stress, making them suitable for automotive, aerospace, and industrial environments.

Applications of High Reliability PCBs

High reliability PCBs are widely used in industries requiring robust, long-term performance:

-

Aerospace and defense systems

-

Automotive ECUs, radar, and ADAS modules

-

Industrial automation and power electronics

-

Medical devices and diagnostic equipment

-

Semiconductor IC testing and ATE boards

-

High-speed computing and networking equipment

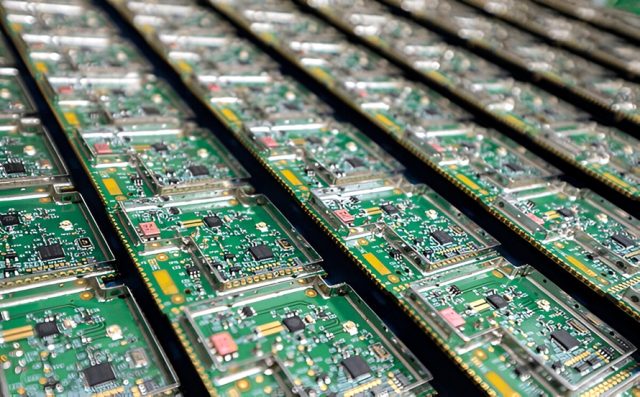

These PCBs ensure stable performance, long operational life, and minimal downtime in critical electronic systems.

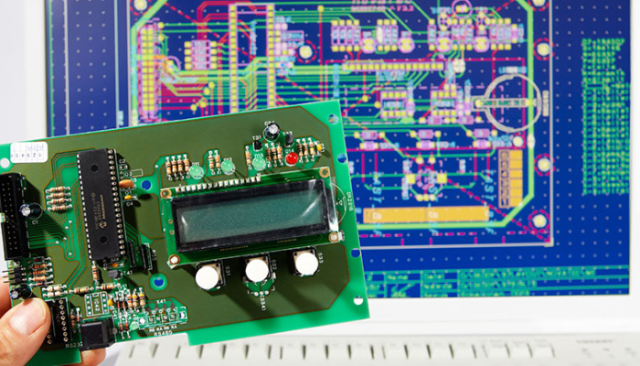

Manufacturing Considerations

Producing high reliability PCBs involves stringent material selection and precision fabrication:

-

High-performance laminates and thermally resistant materials

-

Accurate multilayer lamination and layer alignment

-

Controlled microvia, blind, and buried via formation

-

Surface finish and soldermask reliability

-

Rigorous AOI, X-ray inspection, thermal cycling, and electrical testing

These processes guarantee consistent reliability, thermal stability, and electrical performance over the product’s lifetime.

Conclusion

High Reliability PCBs are essential for critical and high-performance electronic applications. By combining robust materials, advanced multilayer stackups, controlled impedance, and thermal management, these PCBs deliver long-term stability, signal integrity, and durability. From aerospace and automotive to industrial, medical, and semiconductor testing, high reliability PCB technology ensures performance, safety, and confidence in demanding environments.