A Thermal Management PCB is a specialized printed circuit board designed to control, spread, and dissipate heat generated by electronic components. As modern electronic devices operate at higher power levels, higher frequencies, and increased component density, effective thermal management has become a critical factor in ensuring performance stability, reliability, and product lifespan.

By integrating advanced materials, optimized PCB structures, and precision manufacturing processes, thermal management PCBs help prevent overheating, reduce thermal stress, and maintain consistent electrical performance.

Key Features of Thermal Management PCBs

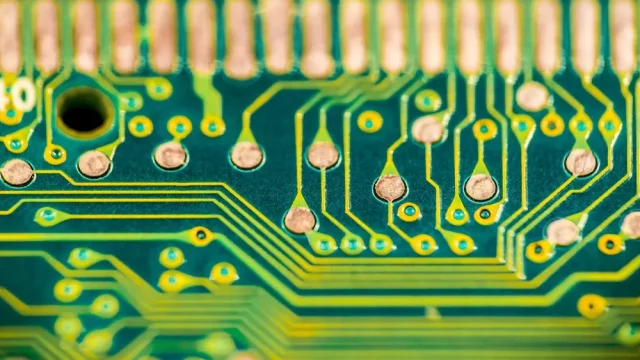

1. Efficient Heat Dissipation Design

Thermal management PCBs are engineered to rapidly transfer heat away from heat-generating components through optimized copper distribution, thermal vias, and heat-spreading layers.

2. Advanced Substrate Materials

Common materials used in thermal management PCBs include:

-

Metal Core PCBs (MCPCB) such as aluminum or copper base

-

High thermal conductivity FR-4

-

Ceramic substrates for extreme thermal performance

-

Hybrid stackups combining metal core and multilayer structures

3. Thermal Vias and Copper Planes

High-density thermal via arrays and thick copper planes provide low thermal resistance paths, enabling efficient heat flow from components to heatsinks or chassis.

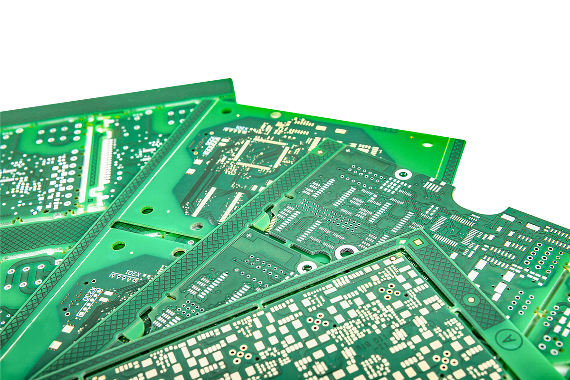

4. Support for High-Power and High-Density Designs

Thermal management PCBs support power devices, LEDs, power modules, and high-current circuits, ensuring stable operation even under continuous high load.

5. Improved Reliability and Product Lifetime

By reducing operating temperature and thermal cycling, thermal management PCBs significantly enhance reliability and extend product lifespan.

Applications of Thermal Management PCBs

Thermal management PCBs are widely used in industries where heat dissipation is critical:

-

Power electronics and power supplies

-

Automotive electronics, EV systems, and ADAS

-

LED lighting and display systems

-

5G base stations and RF power amplifiers

-

Industrial automation and motor control

-

High-performance computing and servers

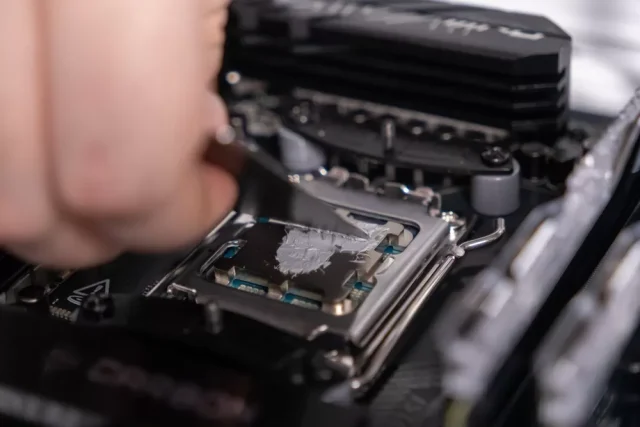

Manufacturing Considerations

Producing high-quality thermal management PCBs requires specialized fabrication techniques and strict quality control, including:

-

Precise thermal simulation and design validation

-

Accurate metal core lamination and insulation thickness control

-

Reliable via filling and copper plating

-

Advanced AOI, thermal resistance testing, and electrical testing

-

Robust mechanical and environmental reliability verification

These processes ensure consistent thermal performance from prototype to mass production.

Conclusion

A Thermal Management PCB is a key enabler for high-power, high-density, and high-reliability electronic systems. Through efficient heat dissipation design, advanced materials, and precision manufacturing, these PCBs ensure stable operation, improved reliability, and long-term performance across demanding applications such as automotive, power electronics, LED, and 5G systems.

Selecting an experienced thermal management PCB manufacturer is essential to achieving optimal thermal performance and product reliability.