A Megtron 6 PCB is a high-performance ultra low loss PCB built with Panasonic Megtron 6 laminate, designed for demanding high-speed digital and high-frequency signal applications. As next-generation electronics continue to push data rates higher—such as advanced SerDes links, high-speed networking, and data center backplanes—standard FR-4 and even some low-loss materials may struggle to meet channel loss and signal integrity requirements.

Megtron 6 PCB materials are widely used when designers require superior signal integrity, stable controlled impedance, and high reliability in complex multilayer PCB structures.

What Is Megtron 6 PCB?

A Megtron 6 PCB refers to a printed circuit board manufactured using Panasonic Megtron 6 series materials, a well-known class of high-speed laminates engineered for:

-

Ultra-low dielectric loss

-

Stable dielectric constant (Dk) performance

-

Reliable impedance control for high-speed channels

-

Strong multilayer manufacturing compatibility

Compared with standard FR-4, a Megtron 6 PCB provides significantly improved high-speed transmission performance, making it ideal for high data rate systems that require long routing lengths and tight compliance margins.

Why Choose Megtron 6 PCB for High-Speed Digital Designs?

In high-speed electronics, the PCB is part of the transmission channel. As frequencies increase, loss and distortion become major challenges. Using a Megtron 6 PCB helps reduce:

-

Insertion loss and attenuation

-

Jitter accumulation and eye closure

-

Reflection caused by impedance variation

-

Crosstalk in high-density routing environments

Megtron 6 PCB materials are commonly selected for designs that must meet strict performance requirements for modern interfaces, especially in high-layer-count and high-density PCB layouts.

Key Advantages of Megtron 6 PCB

1. Ultra-Low Loss Performance (Df) for High-Speed Channels

A Megtron 6 PCB is designed to reduce dielectric loss and improve signal transmission efficiency. Low dissipation factor (Df) helps maintain:

-

Better eye diagram performance

-

Stronger timing margin

-

Lower bit error rate (BER)

-

Longer routing capability at multi-Gbps speeds

This makes Megtron 6 PCB a preferred choice for signal integrity PCB applications where low loss is critical.

2. Stable Dielectric Constant (Dk) for Controlled Impedance PCB Design

Controlled impedance is essential for high-speed digital signals. Megtron 6 PCB materials provide stable Dk performance, supporting impedance targets such as:

-

50Ω single-ended impedance

-

90Ω / 100Ω differential impedance

Stable impedance improves channel consistency, reduces reflections, and supports reliable high-speed transmission.

3. Excellent Differential Pair PCB Routing Performance

Modern high-speed interfaces rely heavily on differential pair routing. A Megtron 6 PCB supports differential pair PCB design by enabling:

-

Consistent differential impedance control

-

Reduced skew and better matching

-

Lower loss over long routing lengths

-

Improved noise immunity and reduced EMI

This is critical for high-speed SerDes channels and data center networking links.

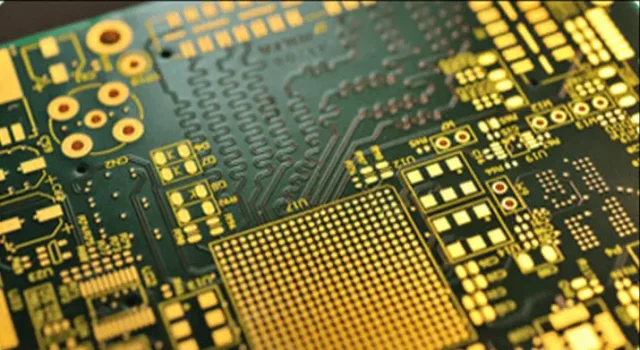

4. Strong Multilayer PCB Compatibility for Complex Stack-Ups

Megtron 6 PCB is commonly used in advanced multilayer designs, including:

-

10-layer to 20+ layer PCB stack-ups

-

High-speed backplane PCB routing structures

-

Dense BGA fanout and fine line PCB routing

-

High reliability PCB requirements for critical systems

Megtron 6 PCB materials support stable lamination performance and reliable production control.

5. Improved Signal Integrity for High-Speed Backplanes and Networking

Megtron 6 PCB materials are often used in backplanes and networking systems because they provide:

-

Lower channel loss at high frequency

-

Better performance for long trace routing

-

Stronger compliance margin for high-speed standards

-

More stable performance across different environments

For advanced networking and computing platforms, Megtron 6 PCB helps improve system reliability and data transmission stability.

Megtron 6 PCB vs Standard Megtron PCB vs FR-4

A Megtron 6 PCB is typically selected when designs require higher performance than standard low-loss laminates. Compared with FR-4, Megtron 6 PCB provides:

-

Much lower insertion loss

-

Better high-frequency stability

-

Improved signal integrity at higher data rates

-

Stronger controlled impedance consistency

Compared with general Megtron PCB materials, Megtron 6 PCB is often chosen for more demanding high-speed requirements such as long channels, backplanes, and next-gen SerDes designs.

Typical Applications of Megtron 6 PCB

Megtron 6 PCB is widely used in:

-

Data center switches, routers, and servers

-

High-speed backplane PCB systems

-

Telecom infrastructure and optical transport equipment

-

PCIe Gen4/Gen5/Gen6 high-speed boards

-

High-speed SerDes and high-speed logic PCB platforms

-

AI accelerator and GPU computing systems

-

High-speed test and validation boards

-

High reliability industrial and communication electronics

Megtron 6 PCB Design Considerations

1. Stack-Up Optimization for Low Loss PCB Routing

Megtron 6 PCB performance depends heavily on stack-up design, including:

-

Correct dielectric thickness selection for impedance targets

-

Dedicated ground reference planes for return paths

-

Proper signal layer arrangement to reduce EMI

-

Balanced structure for multilayer lamination stability

A well-optimized stack-up helps ensure controlled impedance and stable signal integrity.

2. High-Speed Differential Pair Routing Rules

For Megtron 6 PCB designs, differential pair routing should include:

-

Tight impedance control and consistent geometry

-

Accurate length matching and skew control

-

Avoiding unnecessary layer transitions

-

Proper spacing to reduce crosstalk

These practices improve overall channel performance and reliability.

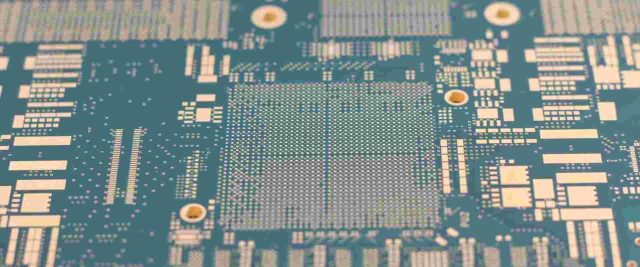

3. Via Control and Backdrill Support

To reduce reflections in high-speed channels, Megtron 6 PCB designs may require:

-

Backdrilling to remove via stubs

-

Optimized via transitions for minimal discontinuity

-

Short via paths and clean reference planes

This helps maintain signal quality for multi-Gbps interconnects.

KKPCB Megtron 6 PCB Manufacturing Capabilities

KKPCB provides professional Megtron 6 PCB manufacturing services with strong engineering and quality control, including:

-

Megtron 6 PCB prototype and mass production

-

Controlled impedance PCB testing and verification

-

Multilayer Megtron 6 PCB fabrication

-

Fine line PCB routing capability for high-density designs

-

High reliability inspection, AOI, and electrical testing

-

Engineering support for stack-up planning and DFM review

We help customers achieve stable performance, consistent quality, and reliable production for Megtron 6 PCB projects.

Conclusion

A Megtron 6 PCB is an advanced ultra low loss PCB solution for high-speed digital and high-frequency electronics requiring excellent signal integrity, stable controlled impedance, and high reliability. With superior performance for long channel routing and next-gen data rates, Megtron 6 PCB is widely used in data centers, telecom infrastructure, high-speed backplanes, and advanced computing systems.

KKPCB delivers high-quality Megtron 6 PCB manufacturing with controlled impedance capability,