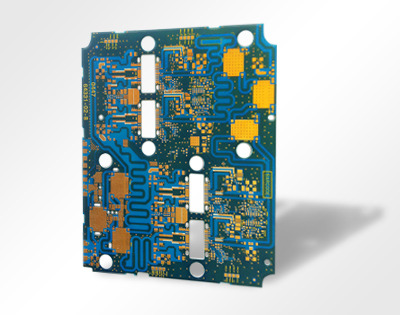

What Is a Low Loss PCB?

Premium Materials, Performance Advantages & Applications

In high-frequency electronics, signal integrity is everything. As data rates climb and RF systems move into the mmWave range, traditional FR-4 PCBs quickly become inadequate due to excessive dielectric loss, copper loss and thermal instability.

At KKPCB, we engineer Low Loss PCBs specifically for demanding applications where consistent impedance, minimal attenuation and long-term reliability are non-negotiable. These boards use advanced substrates—such as PTFE, ceramic-filled epoxies and high-performance hydrocarbon laminates—to reduce insertion loss and maintain stable performance across wide temperature and frequency ranges.

Low loss PCBs are now essential in 5G systems, radar, aerospace, medical imaging, high-speed computing and mission-critical communication equipment.

What Is a Low Loss PCB?

A low loss PCB is a specially engineered printed circuit board designed to minimize signal attenuation during high-frequency transmission. Using materials with low dielectric constant (Dk) and low dissipation factor (Df), these PCBs significantly reduce dielectric loss, radiation loss and conductor loss.

Compared with standard FR-4, a low loss PCB provides:

-

Higher signal integrity

-

Lower insertion loss

-

Better thermal performance

-

More consistent impedance

-

Greater long-term reliability

This makes them indispensable for RF, microwave and millimeter-wave system design.

Key Properties of High-Performance Low Loss PCBs

1. Low Dielectric Constant (Dk)

Dk determines how effectively a PCB material supports electromagnetic wave propagation. A lower Dk:

-

Reduces signal delay

-

Improves impedance stability

-

Enhances high-frequency performance

KKPCB typically uses materials like Rogers RO3000 / RO4000 series and PTFE composites, which offer exceptionally stable Dk values up to 40+ GHz.

2. Ultra-Low Dissipation Factor (Df)

Df—also known as the loss tangent—is the most critical indicator of signal loss.

Lower Df means:

-

Reduced dielectric heating

-

Lower attenuation

-

Cleaner RF transmission

Typical low-loss material Df:

-

PTFE: 0.0009–0.003

-

Rogers RO4350B: 0.0037

-

Ceramic-filled epoxy: 0.004–0.008

Standard FR-4 averages: 0.015–0.020, making it unsuitable for modern RF systems.

3. Thermal Stability & High Reliability

Low loss laminates offer:

-

High thermal conductivity

-

Low CTE (coefficient of thermal expansion)

-

Excellent dimensional stability

These prevent:

-

Warpage

-

Via cracking

-

Impedance drift

Such reliability is essential for aerospace, automotive radar (77–79 GHz) and medical imaging.

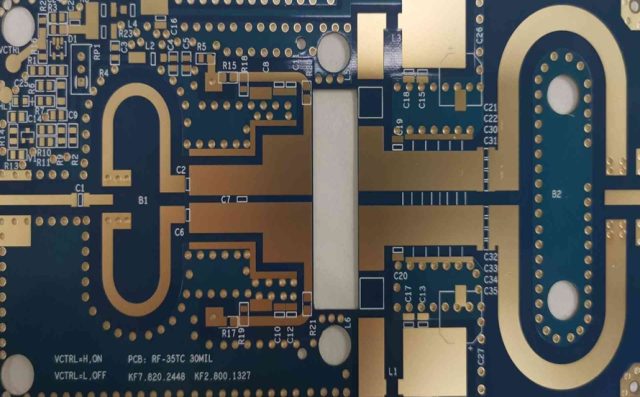

4. Controlled Impedance & Low EMI

Precise impedance control ensures consistent routing for RF and high-speed digital signals.

KKPCB achieves this through:

-

Tight dielectric tolerance

-

Smooth copper foils (RA or reverse-treated)

-

Advanced stackup engineering

-

RF-optimized transmission line design

This minimizes reflections, reduces EMI and enhances signal clarity.

Common Low Loss PCB Materials (KKPCB Recommended)

Material |

Typical Dk |

Typical Df |

Application |

|---|---|---|---|

| PTFE (Teflon) | 2.1–2.6 | 0.0009–0.004 | RF/microwave, mmWave, satellite |

| Ceramic-Filled Epoxy | 3.2–3.8 | 0.003–0.008 | Automotive radar, aerospace |

| Rogers RO3000/4000 | 2.9–3.5 | 0.001–0.003 | 5G, RF modules, phased arrays |

| LCP (Liquid Crystal Polymer) | ~3.0 | ~0.002 | Smartphone antennas, IoT, flex circuits |

Where Are Low Loss PCBs Used? (KKPCB Industry Expertise)

1. 5G Infrastructure & RF Systems

Low Dk / Low Df materials reduce insertion loss in:

-

5G antennas

-

mmWave RF modules

-

Base station beamforming arrays

Performance improvements:

-

Lower energy loss

-

Wider coverage

-

Higher data throughput

2. Aerospace & Satellite Electronics

Space-grade PCBs must withstand:

-

Extreme temperature cycling

-

Radiation exposure

-

Vacuum environments

KKPCB builds low loss PCBs for:

-

Phased-array radar

-

Space communication payloads

-

GPS and GNSS systems

Materials such as RT/duroid 5880LZ guarantee ultra-stable performance.

3. Automotive Radar & ADAS

Systems operating at 77–79 GHz require exceptional precision.

Low loss PCBs provide:

-

Accurate distance measurement

-

Faster response

-

Low signal distortion in harsh environments

Hydrocarbon ceramic laminates are commonly used.

4. Medical Imaging Equipment

MRI, CT and ultrasound rely on low-loss PCB materials to avoid signal degradation.

Benefits include:

-

Improved imaging resolution

-

Lower distortion

-

Stable performance during long operation cycles

5. Data Centers & High-Speed Computing

High-speed interconnects (56–224 Gbps) require ultra-low loss materials to maintain stable eye-diagrams and suppress attenuation.

Low loss PCBs reduce:

-

Insertion loss

-

Crosstalk

-

Copper surface roughness effects

Standard vs Low Loss PCBs (Side-by-Side Comparison)

Property |

Standard FR-4 |

Low Loss PCB |

|---|---|---|

| Dk | 4.2–4.8 | 2.0–3.5 |

| Df | 0.015–0.020 | 0.0009–0.004 |

| Frequency Range | <1–5 GHz | Up to 40+ GHz |

| Signal Loss | High | Minimal |

| Thermal Stability | Moderate | Excellent |

| Impedance Control | Loose | Tight tolerance |

| Cost | Low | Medium–High |

FAQ: Low Loss PCBs (KKPCB Technical Answers)

What’s the difference between low loss and ultra low loss PCBs?

Ultra-low loss PCBs use materials with Df < 0.001, suitable for satellite and deep-space communication.

Do low loss PCBs improve 5G and RF performance?

Absolutely—low Dk/Df improves antenna efficiency, increases range and reduces signal distortion above 24 GHz.

Can low loss PCBs operate above 40 GHz?

Yes, with PTFE, LCP, Rogers and other advanced materials, KKPCB builds RF boards for >40–100 GHz.

Are low loss PCBs more expensive to produce?

Yes, but they deliver dramatically better electrical performance and reliability—especially in RF/microwave designs.