As data rates continue to increase across semiconductor and high-speed electronics, accurate testing becomes more challenging. High Speed Test PCBs are engineered to support multi-gigabit signal transmission, low jitter, and precise impedance control, ensuring reliable validation in demanding test environments.

These specialized PCBs are widely used in semiconductor testing, ATE systems, and high-speed interface verification.

What Is a High Speed Test PCB?

A High Speed Test PCB is a custom PCB specifically designed to test high-speed digital, RF, or mixed-signal circuits. Unlike standard PCBs, high speed test PCBs focus on minimizing signal degradation and maintaining consistent electrical performance under test conditions.

Key characteristics include:

-

Controlled impedance routing

-

Low-loss dielectric materials

-

High-density multilayer stackups

Key Design Requirements for High Speed Test PCBs

To achieve accurate test results, high speed test PCBs must meet several strict requirements:

-

Signal Integrity Control: Reduce reflections, crosstalk, and attenuation at high data rates.

-

Precise Impedance Matching: Ensure consistent impedance across traces, vias, and connectors.

-

Optimized Stackup Design: Provide stable reference planes and predictable transmission paths.

-

High Pin Count Support: Enable dense routing for complex test interfaces.

Each requirement directly impacts test accuracy and repeatability.

Materials and Stackup for High Speed Testing

Material selection is critical in High Speed Test PCB design. Common choices include:

-

Low-loss FR-4 for moderate-speed testing

-

High-performance laminates for multi-GHz applications

-

Hybrid stackups to balance performance and cost

Carefully engineered stackups help reduce insertion loss and skew.

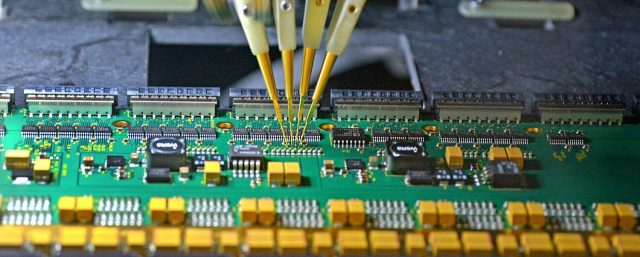

Manufacturing and Quality Control

Manufacturing High Speed Test PCBs requires advanced process control, including:

-

Tight layer registration

-

Precision drilling and plating

-

Controlled impedance testing

-

Electrical continuity and performance verification

These processes ensure each test PCB meets strict performance requirements.

Applications of High Speed Test PCBs

High speed test PCBs are widely used in:

-

Semiconductor IC validation and characterization

-

ATE load boards and interface boards

-

High-speed serial interface testing

-

Communication and data center hardware testing

Each application demands stable, repeatable high-speed performance.

Selecting a High Speed Test PCB Manufacturer

When choosing a High Speed Test PCB manufacturer, look for:

-

Experience with high-speed and test-specific PCB designs

-

Capability in controlled impedance and multilayer PCBs

-

Support for rapid prototyping and small batch builds

-

Comprehensive quality inspection and testing

A reliable partner ensures consistent test results and faster development cycles.

Conclusion

High Speed Test PCBs are essential for validating today’s high-speed electronic systems. By combining controlled impedance, low-loss materials, and precise manufacturing, these PCBs deliver accurate, repeatable test performance.

Partnering with an experienced High Speed Test PCB supplier ensures reliable validation from early prototypes to production-level testing.