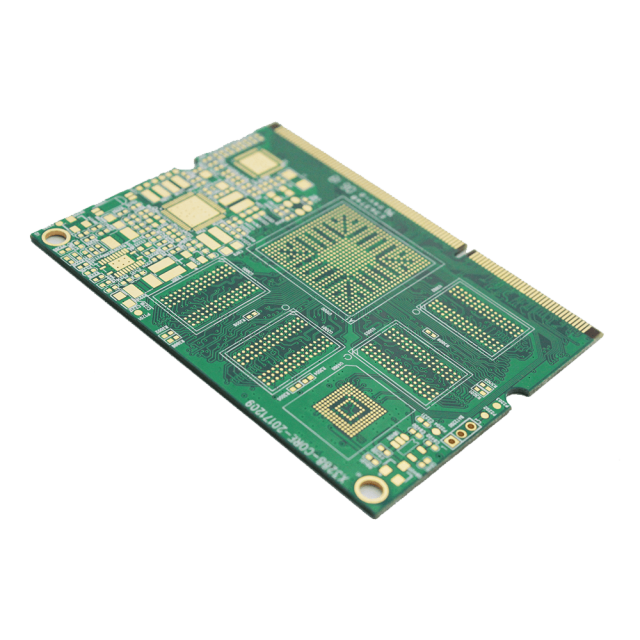

As electronic products continue to evolve toward smaller form factors and higher performance, conventional PCB technologies often reach their limits. The HDI PCB (High-Density Interconnect PCB) overcomes these limitations by enabling ultra-dense routing, shorter signal paths, and enhanced electrical performance.

A professionally engineered HDI PCB is essential for modern high-speed and high-density electronic systems.

What Is an HDI PCB?

An HDI PCB is a printed circuit board that incorporates advanced interconnect technologies such as:

-

Laser-drilled microvias

-

Fine-line trace and space

-

Sequential lamination

These features significantly increase routing density compared to traditional PCBs.

Why HDI PCB Technology Matters

HDI PCBs are widely adopted because they:

-

Support high pin count components

-

Reduce board size and layer count

-

Improve electrical performance

HDI technology enables compact designs without compromising reliability.

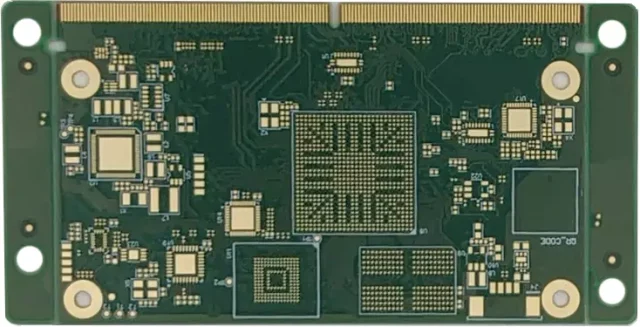

Microvia Structures and Interconnect Design

Microvias are the core of HDI PCB technology. Common structures include:

-

Blind microvias

-

Buried microvias

-

Stacked and staggered microvias

These structures enable efficient signal breakout and routing.

Fine-Line Routing for High-Speed Signals

HDI PCBs support extremely fine trace widths and spacing, allowing:

-

Dense signal routing

-

Improved impedance control

-

Reduced signal path length

Shorter paths help maintain signal integrity at high speeds.

Signal Integrity Advantages of HDI PCBs

HDI technology improves signal integrity by:

-

Minimizing via stubs

-

Reducing parasitic capacitance and inductance

-

Enhancing return path continuity

These benefits are critical for high-speed digital and RF designs.

Power Integrity and Decoupling Optimization

Compact layouts increase power integrity challenges. HDI PCBs address this by:

-

Placing decoupling capacitors close to devices

-

Using low-inductance power paths

-

Optimizing plane structures

Stable power delivery supports reliable system operation.

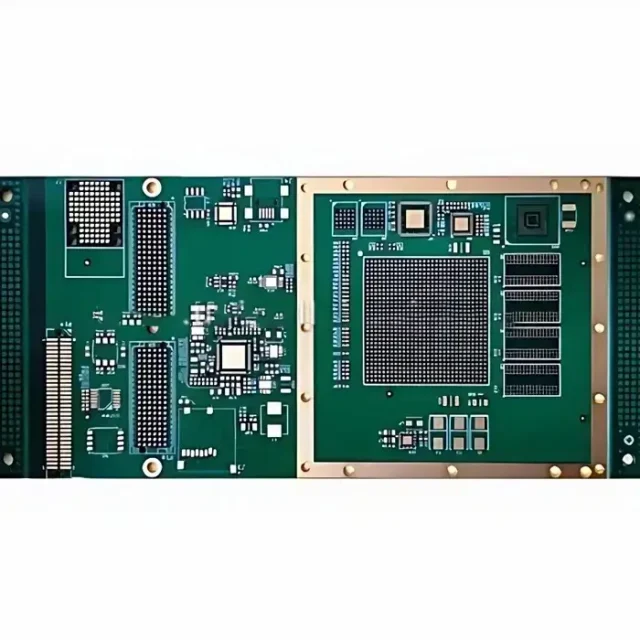

Material Selection and Stackup Design

HDI PCBs commonly use:

-

High-Tg FR-4 for structural stability

-

Low-loss materials for high-speed layers

-

Symmetrical stackups to control warpage

Material selection balances performance, cost, and manufacturability.

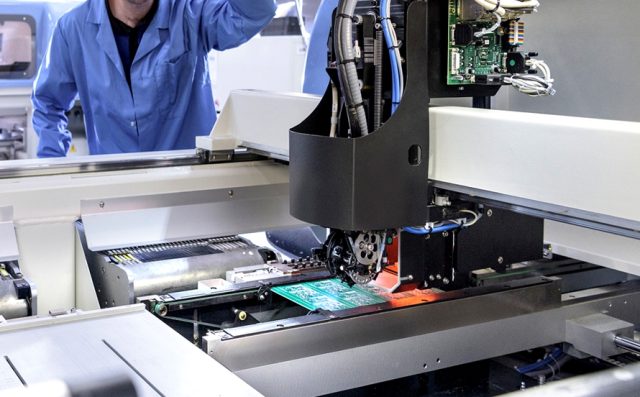

Manufacturing Challenges and Process Control

HDI PCB fabrication requires:

-

Precise laser drilling

-

Reliable via filling and planarization

-

Accurate layer-to-layer registration

Strict process control ensures high yield and consistency.

Typical Applications of HDI PCBs

HDI PCBs are widely used in:

-

Smartphones and consumer electronics

-

High-speed computing and networking systems

-

Medical and automotive electronics

-

Semiconductor test and advanced modules

These applications demand compact size and high performance.

Choosing an HDI PCB Manufacturer

When selecting an HDI PCB supplier, consider:

-

Experience with microvia and sequential lamination

-

Fine-line manufacturing capability

-

Controlled impedance and electrical testing support

-

Engineering collaboration during design review

A skilled manufacturer ensures reliable HDI PCB production.

Conclusion

The HDI PCB is a key enabler of compact, high-speed, and high-density electronic designs. Through microvia technology, fine-line routing, and precise manufacturing, HDI PCBs deliver superior electrical performance and design flexibility.

Partnering with an experienced HDI PCB manufacturer ensures consistent quality from prototype to mass production.