As wireless communication, radar systems, and high-speed data transmission continue to advance, high frequency PCBs have become a critical foundation for modern RF front-end modules. Selecting the right materials and stack-up structures—such as Rogers PCBs, PTFE PCBs, and hybrid PCB stackups—is essential to achieving low loss, stable impedance, and reliable RF performance.

This article explains why high-frequency materials matter, how Rogers, PTFE, and hybrid stackups are used in RF PCB design, and what to consider when buying high-frequency PCBs for high-speed RF front-end applications.

Why High Frequency PCBs Are Critical for RF Front-End Modules

RF front-end modules operate at high frequencies where signal loss, impedance mismatch, and dielectric instability can severely degrade performance. High frequency PCB manufacturing focuses on minimizing these risks by using materials with:

- Low dielectric constant (Dk)

- Low dissipation factor (Df)

- Excellent thermal and dimensional stability

Accurate impedance control and consistent material performance are essential for amplifiers, filters, antennas, and transceiver modules.

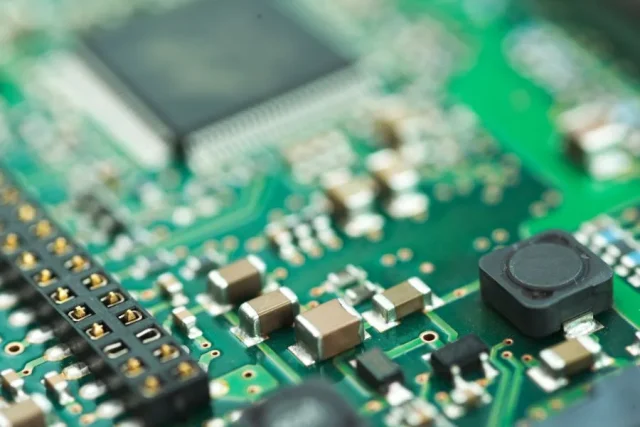

Rogers PCBs for High-Speed RF Applications

Rogers PCB materials are widely used in high-speed and high-frequency designs due to their stable electrical properties.

Key advantages of Rogers PCBs include:

- Tight Dk tolerance for reliable impedance control

- Low dielectric loss for improved signal integrity

- Excellent performance at microwave and millimeter-wave frequencies

Common Rogers materials such as RO4350B and RO4003C are ideal for RF front-end modules requiring repeatable performance.

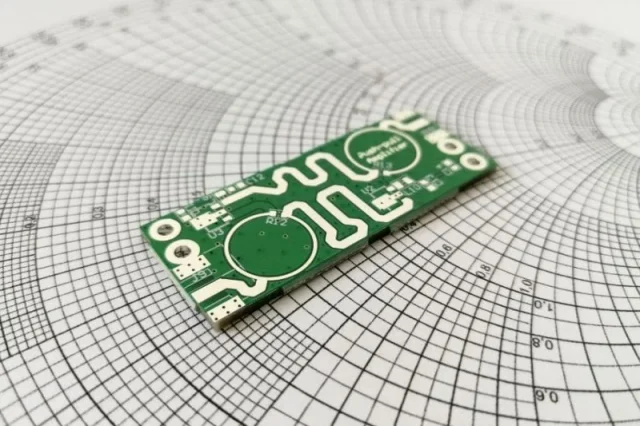

PTFE PCBs for Ultra-High Frequency Performance

For applications operating at very high frequencies, PTFE PCBs offer superior electrical performance.

Benefits of PTFE PCB materials include:

- Extremely low dielectric loss

- Stable performance across wide frequency ranges

- Excellent suitability for microwave and RF circuits

PTFE-based PCBs are commonly used in radar systems, satellite communication, and high-end RF modules where signal loss must be minimized.

Hybrid Stackups: Balancing Performance and Cost

Hybrid PCB stackups combine high-frequency materials such as Rogers or PTFE with standard FR-4 layers.

Advantages of hybrid stackups include:

- Optimized cost-performance balance

- High-frequency signal layers paired with FR-4 control or power layers

- Simplified manufacturing without sacrificing RF performance

Hybrid stackups are ideal for RF front-end modules that require both high-speed RF signals and complex digital control circuits.

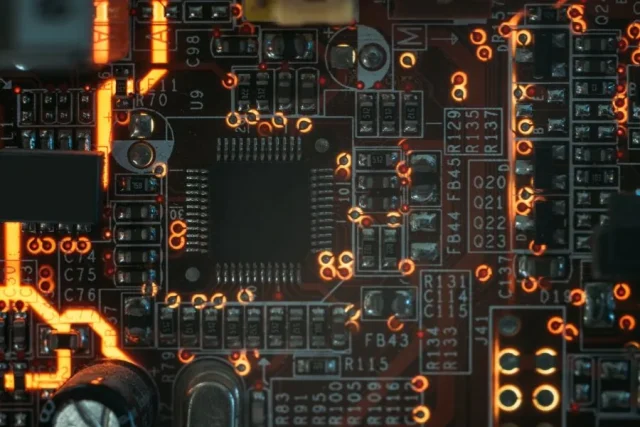

Key Manufacturing Considerations When Buying High Frequency PCBs

When sourcing high frequency PCB manufacturing, it is important to evaluate:

- Material compatibility and lamination process control

- Impedance control accuracy and tolerance

- Copper thickness and surface finish selection

- RF-specific testing and inspection capabilities

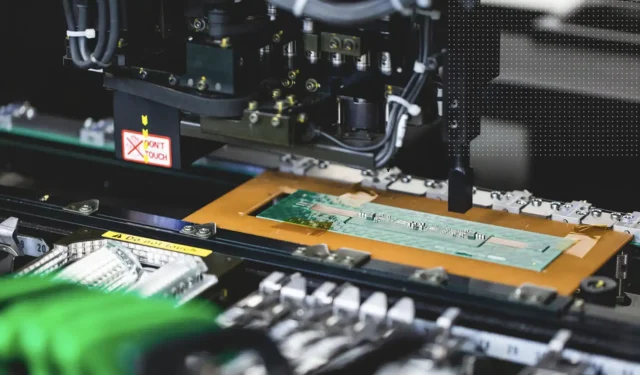

An experienced PCB manufacturer ensures stable performance from prototyping to mass production.

Applications of High Frequency PCBs

High frequency PCBs using Rogers, PTFE, and hybrid stackups are widely used in:

- RF front-end modules

- 5G and wireless communication systems

- Radar and satellite electronics

- High-speed data transmission equipment

- Automotive radar and ADAS systems

Conclusion

Choosing the right high frequency PCB materials and stackup structure is essential for achieving reliable performance in high-speed RF front-end modules. Rogers PCBs, PTFE PCBs, and hybrid stackups each offer unique advantages depending on frequency requirements, performance targets, and cost considerations.

By working with a trusted high-frequency PCB manufacturer, engineers can ensure stable impedance control, low signal loss, and consistent quality throughout the product lifecycle.