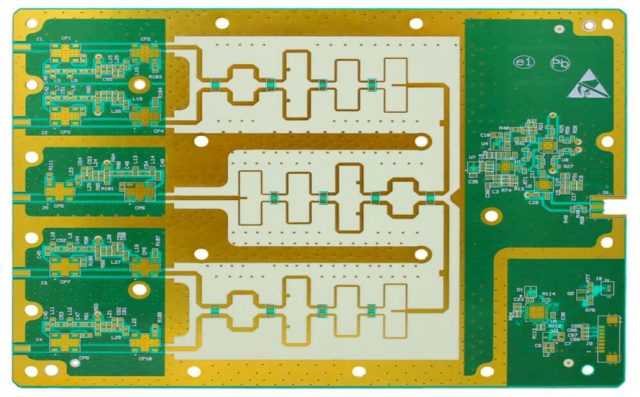

What Is RF-35 PCB?

An RF-35 PCB is a high frequency printed circuit board fabricated using Taconic RF-35 laminate material. It is designed for RF and microwave applications that require low signal loss, stable dielectric performance, and consistent impedance control.

RF-35 is a glass-reinforced PTFE-based laminate filled with ceramic materials to enhance mechanical strength and electrical stability, making it suitable for high frequency circuit designs.

Key Electrical Properties of RF-35 Material

Taconic RF-35 offers a balanced combination of electrical performance and manufacturability. Typical characteristics include:

-

Dielectric constant (Dk): ~3.5

-

Low dissipation factor (Df): typically <0.002 at 10 GHz

-

Excellent frequency stability

-

Low moisture absorption

-

Good thermal reliability

These properties make RF-35 ideal for GHz-level applications where signal loss must be minimized.

Advantages of RF-35 PCB

1. Low Signal Attenuation

RF-35 material reduces insertion loss at high frequencies, ensuring clean and stable RF signal transmission.

It is particularly suitable for:

-

RF power amplifiers

-

Antenna feed networks

-

Microwave transmission lines

-

RF filters and couplers

2. Stable Dielectric Performance

A consistent dielectric constant ensures predictable impedance control and repeatable performance across production batches.

3. Improved Mechanical Strength

Compared with pure PTFE laminates, RF-35 incorporates woven glass reinforcement, which improves:

-

Dimensional stability

-

Mechanical durability

-

Handling performance during fabrication

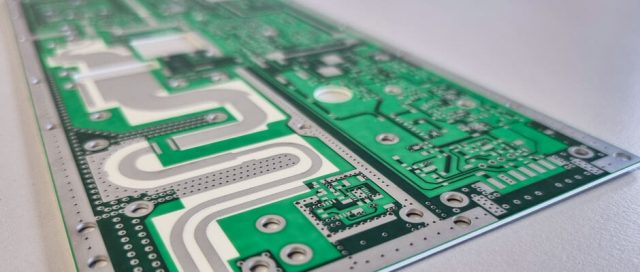

4. Suitable for Multilayer Designs

RF-35 can be used in:

-

Pure RF multilayer PCB

-

Hybrid RF + FR-4 stack-up

-

Mixed signal high frequency designs

Hybrid stack-ups allow cost optimization while maintaining RF performance in critical layers.

Applications of RF-35 PCB

RF-35 PCBs are widely used in:

-

5G communication modules

-

Base station equipment

-

Satellite communication systems

-

Radar systems

-

Automotive radar modules

-

Wireless infrastructure devices

-

High frequency test boards

Its low loss and stable dielectric properties make it suitable for high frequency designs above 1 GHz.

RF-35 PCB vs RO4350B PCB

| Feature | RF-35 PCB | RO4350B PCB |

|---|---|---|

| Base Material | PTFE + Glass | Hydrocarbon Ceramic |

| Dielectric Constant | ~3.5 | ~3.48 |

| Loss Factor | Very Low | Low |

| Fabrication Complexity | Higher | Easier |

| Application Focus | RF / Microwave | RF + High Speed Digital |

RF-35 offers lower loss performance, while RO4350B provides easier processing and broader digital compatibility.

Manufacturing Considerations for RF-35 PCB

Producing a high-quality RF-35 PCB requires:

-

Accurate impedance simulation

-

Tight thickness tolerance control

-

Specialized drilling and plating processes

-

Surface treatment compatible with RF performance

-

Strict quality inspection

Due to its PTFE base, proper fabrication experience is critical to ensure stable production yield.

Conclusion

RF-35 PCB provides excellent low loss performance and stable dielectric properties for RF and microwave circuit designs. It is an ideal solution for high frequency communication, radar systems, and advanced wireless applications.

Choosing an experienced RF PCB manufacturer ensures optimized stack-up design, precise impedance control, and reliable long-term performance.