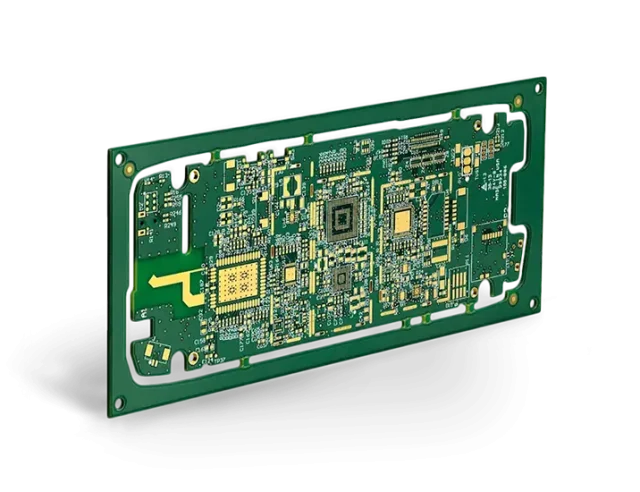

What Is an Impedance Controlled PCB?

An Impedance Controlled PCB is a printed circuit board designed with precisely engineered impedance values for high-speed or high-frequency signal paths.

These PCBs ensure signal integrity, minimal reflection, and low insertion loss, which are critical for RF modules, 5G routers, high-speed digital circuits, automotive electronics, and sensor interfaces.

Key Requirements for Impedance Controlled PCB

High-quality Impedance Controlled PCBs must meet the following requirements:

-

Precise impedance tolerance (typically ±5% or better)

-

Stable dielectric constant (Dk) for consistent high-speed performance

-

Low dielectric loss (Df) for RF and high-speed signals

-

Optimized trace width, spacing, and layer stack-up

-

Reliable connector and interconnect performance

-

Thermal stability for operational environments

Meeting these requirements ensures minimal signal distortion and accurate high-speed transmission.

Material Selection for Impedance Controlled PCB

Material choice is critical for maintaining impedance:

-

RO4835, RO4350B, RF-35 laminates – for RF and microwave applications

-

Megtron 7 / Low-loss FR-4 hybrid laminates – for ultra-high-speed digital circuits

-

Ceramic or rigid-flex materials – for stable impedance in harsh environments

Correct material selection ensures low insertion loss and precise signal propagation.

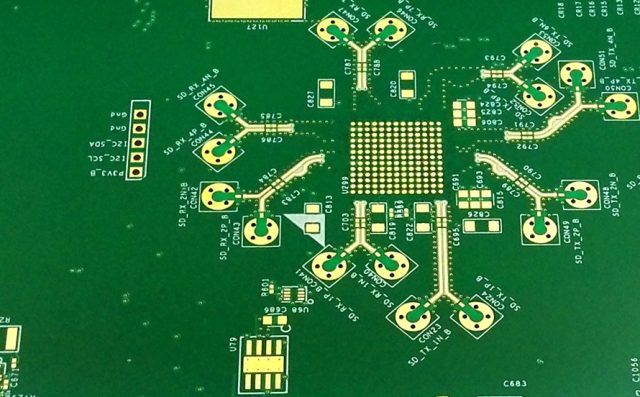

Design Considerations for Impedance Controlled PCB

Effective design strategies include:

-

Controlled microstrip and stripline trace geometry

-

Optimized power and ground plane design

-

Via fencing and shielding to reduce crosstalk

-

Proper connector and RF launch design

-

Minimized trace discontinuities and stub lengths

-

Thermal management to prevent dielectric changes

Proper design ensures high-speed data integrity and reliable RF performance.

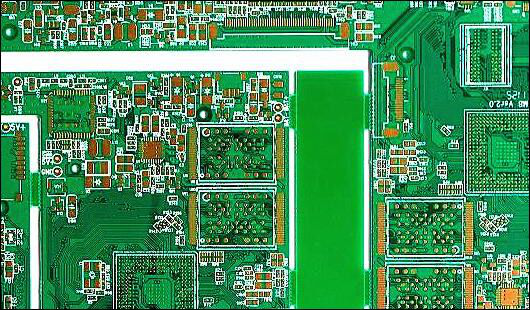

Manufacturing Challenges of Impedance Controlled PCB

Producing a reliable Impedance Controlled PCB requires:

-

Strict dielectric and copper thickness tolerances

-

High-precision layer registration

-

Controlled copper surface roughness

-

Advanced lamination and plating processes

-

Comprehensive impedance and electrical testing

Experienced PCB manufacturers ensure consistent impedance and signal integrity.

Applications of Impedance Controlled PCB

Impedance Controlled PCBs are used in:

-

5G routers and mmWave modules

-

RF Test PCBs and sensor modules

-

High-speed networking equipment

-

Automotive electronics (ADAS, radar, LiDAR)

-

Semiconductor functional test boards

-

IoT and smart device high-speed interfaces

They are essential wherever high-speed signals and RF accuracy are critical.

Conclusion

An Impedance Controlled PCB is essential for high-speed digital and RF applications that require stable signal integrity, low insertion loss, and precise impedance control.

Working with a professional Impedance Controlled PCB manufacturer ensures reliable high-frequency performance, accurate impedance, and repeatable results from prototype to volume production.