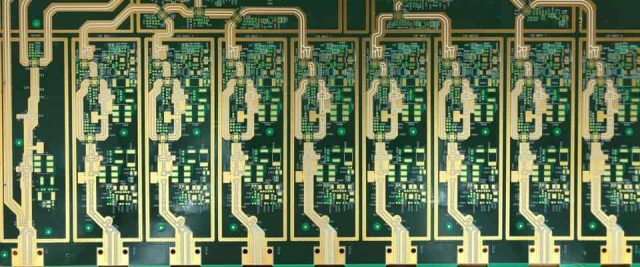

Taconic PCBs are high-performance printed circuit boards engineered with low-loss dielectric laminates designed for RF, microwave, and high-speed digital applications. Taconic materials are widely recognized for their stable dielectric constant (Dk), low dissipation factor (Df), and thermal reliability, making them ideal for applications where signal integrity and frequency performance are critical.

Key Advantages of Taconic PCB Materials

Taconic PCBs provide a combination of properties that enable consistent high-frequency performance:

-

Low Dielectric Loss: Taconic laminates minimize insertion loss, preserving signal amplitude and reducing attenuation in high-speed traces.

-

Stable Dielectric Constant (Dk): Predictable impedance and controlled propagation delays ensure signal fidelity across multi-GHz signals.

-

Thermal Stability: Taconic PCB materials maintain electrical and mechanical properties across elevated operating temperatures and repeated thermal cycles.

-

Moisture Resistance: Reduced moisture absorption prevents dielectric constant shifts, critical for high-frequency RF applications.

These advantages make Taconic PCB the preferred choice for 5G, radar, satellite communications, and high-speed digital interconnects.

Electrical Performance in RF and Microwave Systems

Taconic materials are engineered to optimize signal integrity in complex high-frequency systems. They provide:

-

Controlled impedance for microstrip, stripline, and coplanar waveguide routing

-

Minimal crosstalk in dense interconnect designs

-

Reduced phase distortion and group delay variations

-

Consistent high-frequency performance across different manufacturing lots

This ensures reliable operation in multi-GHz and mmWave applications, where even minor dielectric inconsistencies can affect system performance.

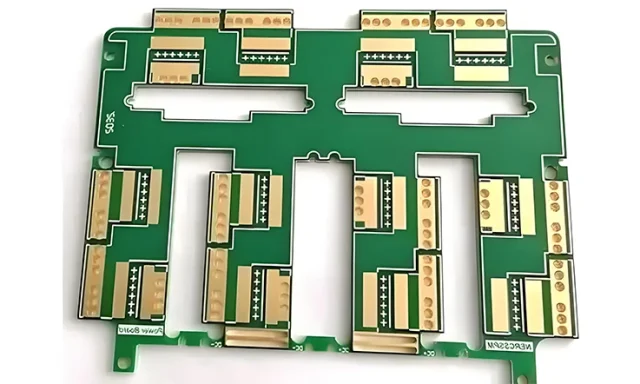

Mechanical and Thermal Considerations

High-performance Taconic PCBs also address mechanical and thermal challenges:

-

Tight control of coefficient of thermal expansion (CTE) reduces stress on plated through holes and solder joints

-

High Tg laminates prevent deformation under reflow or wave soldering

-

Mechanical rigidity supports fine-pitch component assembly and dense via structures

-

Compatibility with multilayer HDI stackups ensures both signal integrity and structural reliability

These properties make Taconic PCBs suitable for mission-critical and high-reliability RF systems.

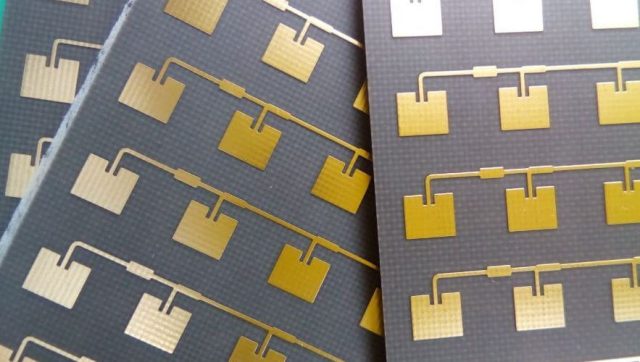

Applications of Taconic PCB

Taconic PCBs are commonly used in:

-

5G base stations and mmWave antennas

-

Radar and satellite communication modules

-

High-speed digital systems and backplanes

-

RF front-end modules and transceivers

-

Test and measurement equipment for high-frequency signals

In these applications, Taconic PCB materials enable long-distance signal propagation, minimal loss, and precise impedance control, ensuring system-level performance.

Engineering Perspective

Selecting Taconic PCB materials allows engineers to balance electrical performance, thermal stability, and mechanical reliability in demanding RF and high-speed designs. By combining low-loss dielectric properties, controlled Dk, and thermal resilience, Taconic PCBs deliver predictable, repeatable performance in advanced electronic systems.

KKPCB provides Taconic PCB design guidance, stackup engineering, and manufacturing support, ensuring high-frequency systems achieve optimal performance with consistent quality.