A Thermal Management PCB is a specialized printed circuit board designed to effectively manage heat generated by high-power components. As electronic devices become more compact and operate at higher currents and voltages, efficient heat dissipation is critical to maintain performance, prevent component failure, and ensure long-term reliability.

These PCBs are widely used in power electronics, LED lighting, automotive electronics, RF and 5G modules, high-speed computing, and industrial control systems, where temperature management directly impacts system efficiency and longevity.

Key Features of Thermal Management PCBs

1. Metal Core PCB (MCPCB)

Thermal management PCBs often use a metal core (aluminum or copper) to transfer heat away from critical components quickly, reducing hot spots and improving system reliability.

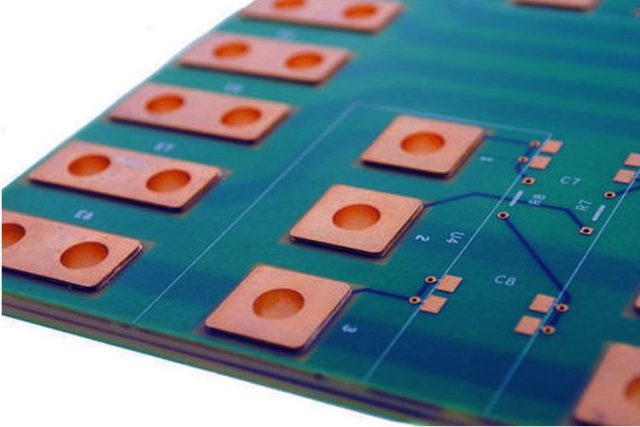

2. Thermal Vias and Heat Pipes

Thermal vias are strategically placed to conduct heat from component pads to inner copper layers or heat sinks, ensuring uniform temperature distribution.

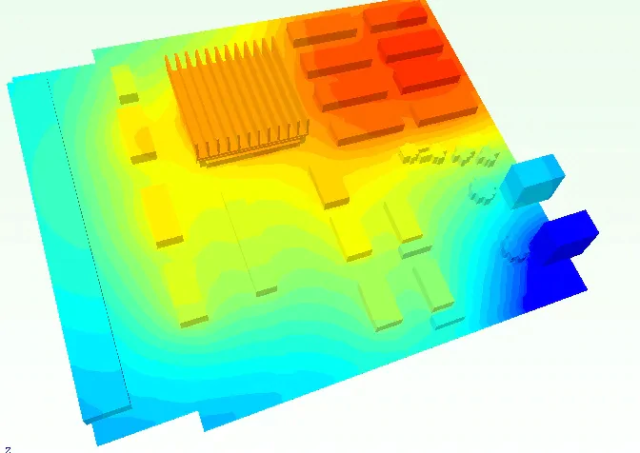

3. Optimized Copper Planes

High-power PCBs utilize thick copper layers to handle high current loads while simultaneously spreading heat across the board, minimizing thermal gradients.

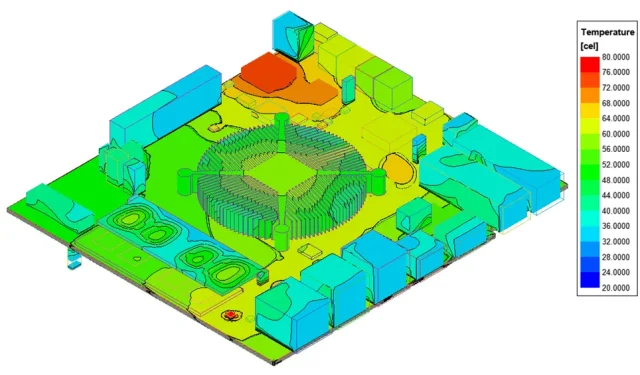

4. Controlled Component Placement

Component placement is optimized to reduce heat concentration, prevent thermal interference between adjacent ICs, and improve overall PCB cooling efficiency.

5. Integration with Active and Passive Cooling

Thermal management PCBs can be combined with heat sinks, fans, or thermal interface materials (TIMs) to further enhance heat dissipation in demanding applications.

Applications of Thermal Management PCBs

Thermal management PCBs are critical in:

-

Automotive electronics and ADAS modules

-

High-power LED lighting and display systems

-

RF and microwave communication systems, including 5G modules

-

Power management and industrial control boards

-

High-performance computing and GPU boards

These applications demand effective thermal control, reliable electrical performance, and long-term system stability.

Manufacturing Requirements for Thermal Management PCBs

Producing high-quality thermal management PCBs requires:

-

Precision lamination and metal core integration

-

Accurate thermal via drilling and plating

-

Optimized copper thickness and plane design

-

Controlled impedance and signal integrity for high-speed traces

-

Prototype, small batch, and large-scale production support

Strict process control ensures consistent thermal performance, electrical reliability, and manufacturing yield.

Why Thermal Management PCB Quality Matters

Inferior thermal management PCBs can cause:

-

Component overheating and failure

-

Signal degradation due to thermal expansion

-

Reduced test yield in semiconductor and high-speed applications

-

Shortened system lifespan and reliability issues

High-quality thermal management PCBs guarantee efficient heat dissipation, stable electrical performance, and long-term reliability, even in high-power or high-density designs.

Conclusion

A Thermal Management PCB is essential for high-power, high-density, and high-speed electronic systems. By integrating metal core layers, thermal vias, optimized copper planes, and effective cooling strategies, these PCBs deliver reliable thermal performance, electrical stability, and extended component life.

Partnering with an experienced thermal management PCB manufacturer ensures efficient heat control, higher system reliability, and long-term performance in demanding electronic applications.