Buried Via PCB: Enabling High-Density Interconnection Beyond Conventional Multilayer Boards

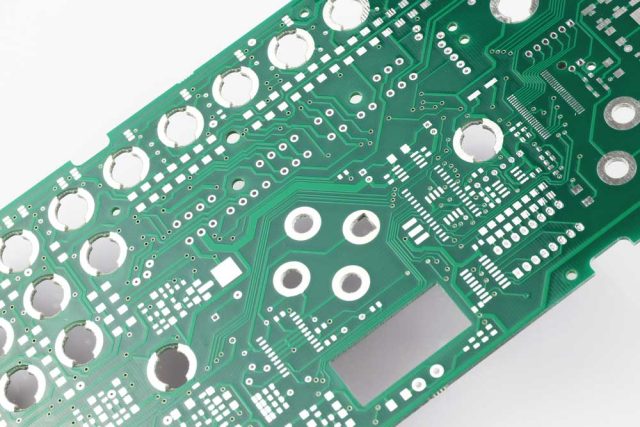

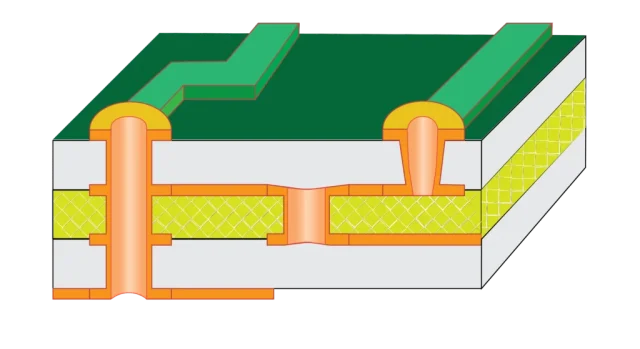

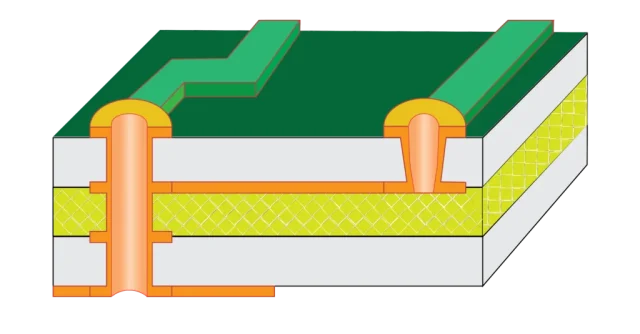

A Buried Via PCB is a multilayer printed circuit board in which vias connect only internal layers and do not extend to the outer layers. Unlike through-hole vias, buried vias are completely embedded within the PCB stackup, enabling higher routing density, improved signal integrity, and more efficient layer utilization.

As electronic systems continue to demand compact form factors, high-speed interfaces, and complex power distribution, Buried Via PCB technology has become a critical solution for high-density, high-performance designs.

Why Buried Via PCB Is Essential for High-Density Designs

Traditional through vias occupy surface routing space and introduce parasitic inductance and stubs. A Buried Via PCB eliminates these limitations by confining vias to specific internal layers.

Key benefits of Buried Via PCB designs include:

-

Increased routing density on outer layers

-

Reduced via stub effects in high-speed signals

-

Improved impedance continuity

-

Enhanced signal integrity for multi-gigabit links

-

Better power and ground plane integrity

By freeing surface layers for component placement and fine-line routing, Buried Via PCBs enable denser and more reliable designs.

Signal Integrity Advantages of Buried Via PCB Architectures

High-speed digital and RF signals are extremely sensitive to discontinuities. Buried Via PCB structures significantly reduce impedance discontinuities caused by unused via barrels.

From a signal integrity perspective, Buried Via PCBs offer:

-

Shorter via transition paths

-

Lower parasitic capacitance and inductance

-

Reduced reflection and insertion loss

-

Improved eye diagram opening

-

Better phase consistency across layers

For high-speed interfaces such as PCIe, Ethernet, and high-frequency RF paths, Buried Via PCB technology delivers measurable performance gains.

Buried Via PCB vs Through Via and Blind Via

In advanced PCB design, different via structures serve different purposes:

-

Through Via PCB: Simple, low cost, but consumes routing space and creates stubs

-

Blind Via PCB: Connects outer layers to inner layers, improves density

-

Buried Via PCB: Connects only internal layers, maximizes routing efficiency

A Buried Via PCB is often combined with blind vias in HDI and high-layer-count designs to create an optimized via hierarchy that balances performance, density, and manufacturability.

Stackup Design Considerations for Buried Via PCB

Proper stackup planning is critical in Buried Via PCB engineering. Designers must define via spans, lamination sequences, and dielectric thicknesses early in the design phase.

Key stackup considerations include:

-

Clear definition of buried via start and end layers

-

Balanced copper distribution to prevent warpage

-

Precise dielectric thickness control for impedance accuracy

-

Dedicated reference planes for high-speed layers

-

Compatibility with sequential lamination processes

A well-optimized Buried Via PCB stackup directly impacts yield, reliability, and electrical performance.

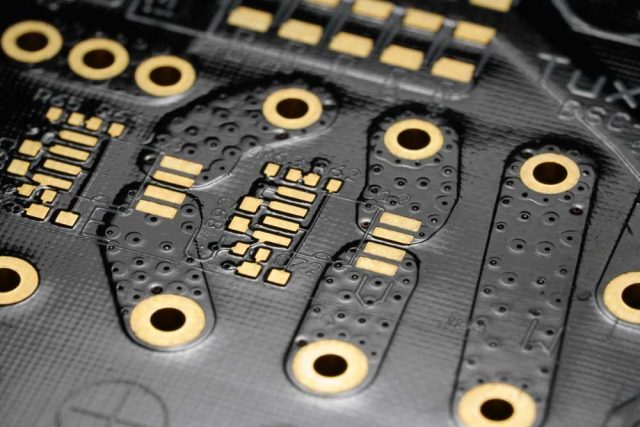

Manufacturing Complexity of Buried Via PCBs

Fabricating a Buried Via PCB requires advanced manufacturing capabilities, including sequential lamination and tight registration control.

Key manufacturing steps include:

-

Inner layer drilling and plating for buried vias

-

First-stage lamination to encapsulate buried vias

-

Additional drilling for blind or through vias

-

Multiple lamination cycles for complex stackups

-

Electrical testing at intermediate stages

Because buried vias cannot be accessed after lamination, Buried Via PCB manufacturing demands extremely high process accuracy and inspection standards.

Reliability and Thermal Performance of Buried Via PCBs

From a reliability standpoint, Buried Via PCBs offer improved mechanical stability because vias are protected within the laminate structure.

Advantages include:

-

Reduced stress concentration compared to through vias

-

Improved thermal cycling reliability

-

Lower risk of via cracking in high-layer-count boards

-

Better heat distribution through internal copper layers

These characteristics make Buried Via PCBs suitable for mission-critical and long-life applications.

Applications of Buried Via PCB Technology

Buried Via PCB designs are widely adopted in:

-

High-speed data center switches and servers

-

5G baseband and network equipment

-

Aerospace and satellite electronics

-

Medical imaging and diagnostic systems

-

Industrial automation and control platforms

In each case, Buried Via PCBs enable higher integration without sacrificing electrical performance.

KKPCB Buried Via PCB Capabilities

KKPCB provides comprehensive Buried Via PCB engineering and manufacturing services, including:

-

Buried via and blind via PCB fabrication

-

High-layer-count PCB stackup design support

-

Controlled impedance and high-speed routing optimization

-

Sequential lamination and advanced registration control

-

DFM, DFI, and reliability-focused process validation

KKPCB ensures that every Buried Via PCB meets strict electrical, mechanical, and reliability requirements.

Conclusion

A Buried Via PCB is a key enabler for high-density, high-speed electronic systems. By eliminating unnecessary via stubs and maximizing internal routing efficiency, Buried Via PCB architectures deliver superior signal integrity, improved reliability, and greater design flexibility.

For advanced applications where performance and density are non-negotiable, Buried Via PCB solutions provide a clear technical advantage. KKPCB combines engineering expertise with precision manufacturing to deliver reliable Buried Via PCBs from prototype to mass production.