WiFi PCB Design Guide for High-Speed Connectivity

Introduction

WiFi connectivity is everywhere—from mobile devices to smart home systems and industrial machinery. At the heart of all these wireless systems lies the WiFi PCB, a specialized circuit board engineered to process, transmit, and receive high-frequency wireless signals.

This guide explores the structure, design principles, materials, RF layout challenges, and next-generation requirements for WiFi 6, WiFi 7, and 5G-enabled PCB designs.

1. What Is a WiFi PCB?

A WiFi PCB is the hardware platform enabling wireless communication between devices and WiFi access points. It integrates:

-

RF circuitry

-

WiFi chipsets

-

Antennas

-

Microcontrollers

-

Matching networks

-

Power management blocks

WiFi PCBs operate on 2.4 GHz, 5 GHz, and now 6 GHz (WiFi 6E/7) frequency bands, providing high-speed, high-capacity, and low-latency wireless communication.

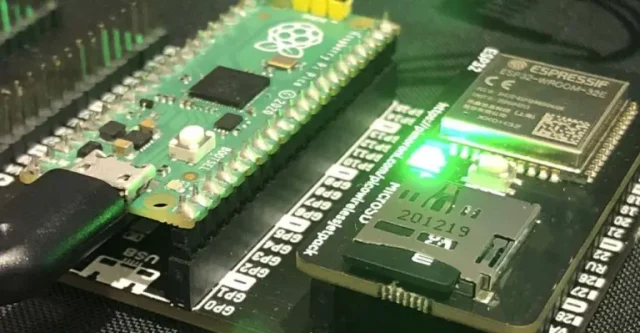

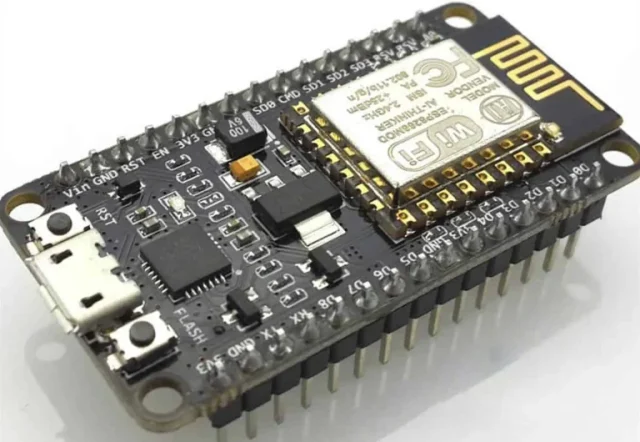

2. Core Components of a WiFi PCB Module

● Microcontroller (MCU)

Acts as the processing brain, running firmware and managing system control.

● WiFi Chipset (Baseband + RF Front End)

-

Baseband handles modulation/demodulation and data encoding

-

RF front-end manages transmission and reception

● PAs and LNAs

-

Power Amplifier (PA): Boosts transmit power

-

Low-Noise Amplifier (LNA): Enhances weak incoming signals

● RF Matching Network

Ensures 50-ohm impedance matching between RF stages and antenna.

● Filters & Oscillators

Stabilize frequency, remove unwanted harmonics, enhance signal cleanliness.

● Flash Memory

Stores firmware, calibration parameters, and configuration data.

● Interfaces (SPI / SDIO / USB / PCIe)

Used for high-speed data exchange with host systems.

3. WiFi PCB Design Guidelines

3.1 Component Placement

-

Keep RF chipset close to the antenna

-

Isolate noisy switching power circuits from RF blocks

-

Position decoupling capacitors as close as possible to IC pins

3.2 Impedance Control & Signal Integrity

-

50-ohm single-ended / 100-ohm differential routing is essential

-

Maintain a solid, continuous ground plane

-

Avoid sharp 90° routing corners

3.3 Power Integrity

-

Use LC filters, ferrite beads, and LDO regulators

-

Apply multi-stage decoupling (0.1uF + 1uF + 10uF)

-

Minimize noise coupling into RF sections

4. WiFi PCB Antenna Design

Common Antenna Types

-

Dipole Antenna – for routers and consumer electronics

-

Patch Antenna – compact IoT devices

-

Monopole Antenna – handheld devices

-

PCB Antenna – cost-efficient, space-saving designs

Placement Guidelines

-

Place antenna at the board edge

-

Keep away from large ground planes and metal structures

-

Maintain a clear keep-out zone on all layers

Antenna Feed & Matching

-

Use 50-ohm feed lines

-

Include π-matching networks for tuning

-

Ensure antenna tuning after final enclosure assembly

Why Dk and Df Are Essential for Superior Wireless Performance

-

Lower Df = Less signal attenuation

-

Stable Dk = Accurate impedance control

6. WiFi PCB Layout Considerations

Routing

-

Avoid long RF traces

-

Keep RF/digital separated

-

Use short via transitions

Ground & Shielding

-

Use ground stitching vias around RF zones

-

Maintain uninterrupted reference planes

Thermal Management

-

Use thermal vias below PA chips

-

Apply copper pours around hot zones

7. Types of WiFi PCBs

-

Single-Layer – small IoT devices

-

Multilayer – routers, laptops, advanced modules

-

Flexible PCB – wearables

-

Rigid-Flex PCB – automotive, medical equipment

8. Applications

-

Consumer electronics

-

Smart home devices

-

Medical monitoring systems

-

Automotive infotainment / ADAS

-

Industrial automation and robotics

9. Trends in WiFi PCB Design

-

WiFi 6 / WiFi 6E / WiFi 7 high-speed PCB

-

WiFi + 5G coexistence architectures

-

Advanced materials for low-loss RF

-

Eco-friendly PCB manufacturing

Conclusion

Designing a high-performance WiFi PCB requires expertise in RF engineering, materials science, signal integrity, and power management. As technologies like WiFi 7 and 5G push wireless performance limits, modern PCB designs must adapt with precision layout, advanced laminates, optimized antennas, and robust EMI strategies.

If you need professional WiFi PCB design & manufacturing, our engineering team can assist with RF simulation, controlled impedance stackup, antenna tuning, and full PCBA services.