What Is a Taconic PCB?

A Taconic PCB is a printed circuit board manufactured using high-performance laminates produced by Taconic Advanced Dielectric Division. These materials are widely recognized for their excellent high-frequency electrical properties, low dielectric loss, and stable performance in demanding RF and microwave applications.

Taconic materials are commonly used in:

-

RF PCB

-

Microwave PCB

-

5G communication PCB

-

Radar systems

-

Satellite communication

-

High speed digital systems

When signal performance at GHz or mmWave frequencies is critical, Taconic PCB materials provide reliable and predictable results.

Why Choose Taconic PCB Materials?

Taconic laminates are engineered to deliver superior electrical stability and low insertion loss in high-frequency circuits.

Low Dissipation Factor (Df)

Taconic PTFE-based materials offer very low Df, reducing signal attenuation and improving RF efficiency.

Stable Dielectric Constant (Dk)

Consistent Dk ensures accurate impedance control and reliable transmission line performance.

Excellent Thermal Stability

Taconic materials maintain performance across wide temperature ranges, ideal for automotive and aerospace electronics.

Low Moisture Absorption

Improves reliability in humid or harsh environments.

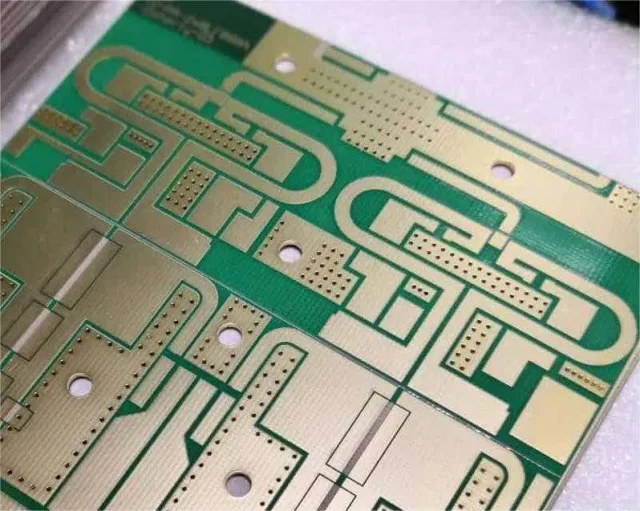

Common Taconic PCB Material Series

Some popular Taconic laminate families include:

RF-35 / RF-45 Series

-

Hydrocarbon ceramic laminates

-

Cost-effective alternative to PTFE

-

Suitable for 5G and RF PCB

TLY Series

-

PTFE woven glass reinforced

-

Very low loss performance

-

Ideal for microwave PCB

TLX Series

-

High mechanical stability

-

Used in RF and high-speed digital designs

Each series provides specific performance benefits depending on frequency range and application requirements.

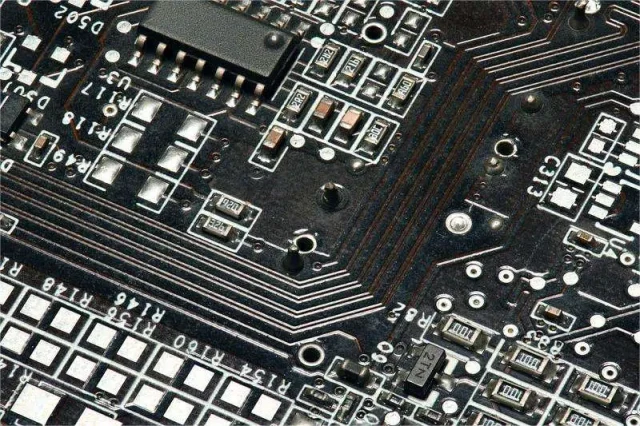

Taconic PCB vs Standard FR-4

| Feature | Taconic PCB | Standard FR-4 |

|---|---|---|

| Frequency Performance | Excellent | Limited |

| Dissipation Factor | Very Low | Higher |

| Impedance Stability | High | Moderate |

| RF Efficiency | Superior | Not Ideal |

For RF PCB and high frequency PCB applications, Taconic materials significantly outperform conventional FR-4.

Applications of Taconic PCB

Taconic PCBs are widely used in:

-

5G base station PCB

-

RF power amplifier PCB

-

mmWave antenna PCB

-

Automotive radar PCB

-

Satellite communication systems

-

High speed networking equipment

-

Military and aerospace electronics

These applications require minimal signal loss and precise impedance control, which Taconic materials deliver consistently.

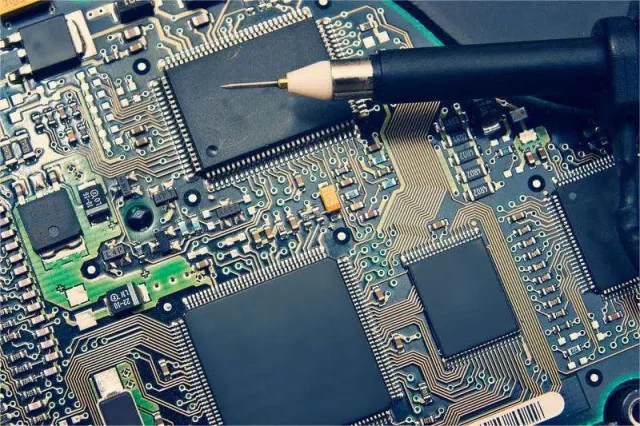

Manufacturing Considerations for Taconic PCB

Fabricating Taconic PCB requires specialized expertise:

-

Controlled lamination process

-

Careful drilling for PTFE materials

-

Copper surface treatment optimization

-

Precise impedance verification

-

Strict quality control

Due to the unique characteristics of PTFE-based laminates, working with an experienced high frequency PCB manufacturer is essential.

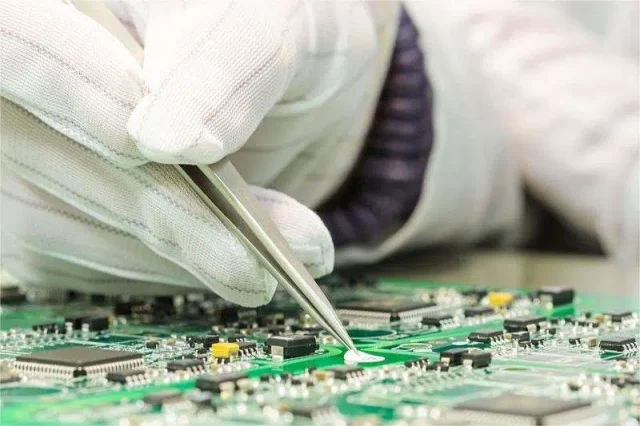

Choosing a Reliable Taconic PCB Supplier

A professional Taconic PCB supplier should provide:

-

Multiple Taconic laminate options

-

RF stack-up design support

-

Controlled impedance calculation

-

High frequency testing capability

-

Prototype and volume production services

Selecting the right Taconic PCB partner ensures stable RF performance, reduced signal loss, and long-term reliability.