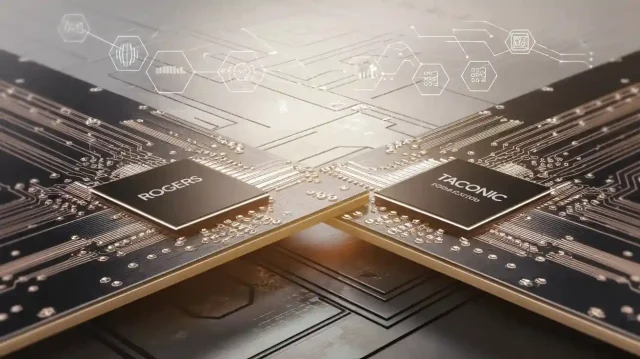

Taconic PCB materials are widely recognized in high-frequency and microwave PCB applications for their low dielectric loss, stable dielectric constant (Dk), and high thermal reliability. As RF and high-speed digital systems continue to demand higher bandwidths and tighter signal integrity, Taconic laminates provide a proven solution for minimizing insertion loss and maintaining performance consistency.

Material Properties of Taconic PCB

Taconic PCBs are engineered using PTFE-based laminates combined with glass or ceramic fillers to achieve a balance of mechanical strength, thermal performance, and electrical stability. Key material characteristics include:

-

Low dissipation factor (Df) for reduced signal attenuation

-

Stable dielectric constant (Dk) across frequency ranges, ensuring controlled impedance

-

High glass transition temperature (Tg) and thermal stability

-

Low moisture absorption for environmental reliability

These properties make Taconic PCB laminates suitable for RF front-end modules, 5G communications, radar systems, and satellite electronics.

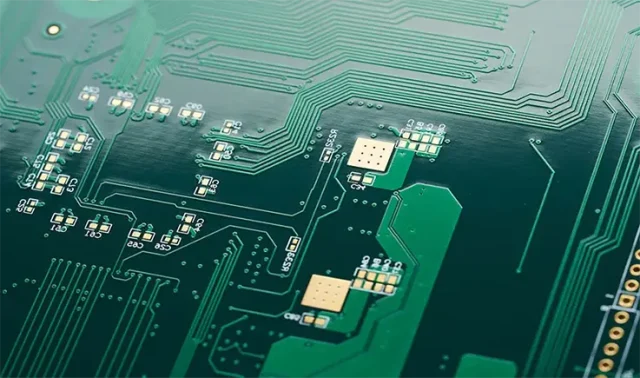

Signal Integrity and High-Frequency Performance

Maintaining signal integrity in high-frequency PCBs is a core engineering challenge. Taconic PCBs address these challenges by providing:

-

Reduced insertion loss for microwave and mmWave circuits

-

Predictable phase response across signal paths

-

Low crosstalk between densely routed lines

-

Stable impedance for differential and single-ended traces

By minimizing dielectric and conductor losses, Taconic PCBs enable reliable signal transmission at multi-gigahertz frequencies, supporting advanced communication and radar applications.

Thermal and Mechanical Considerations

Taconic laminates are designed to withstand the thermal stresses common in RF and high-speed PCB assemblies. Key engineering benefits include:

-

High Tg and low CTE for reduced board warpage

-

Enhanced mechanical stability in multilayer stackups

-

Improved reliability for solder joints and via connections under thermal cycling

-

Dimensional stability in precision microwave circuits

These thermal and mechanical characteristics ensure that Taconic PCBs maintain long-term performance even in demanding operational environments.

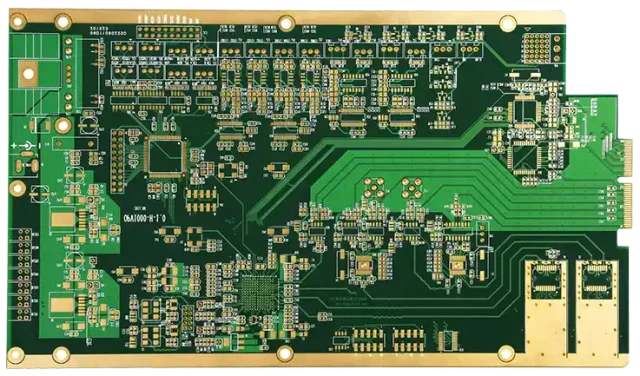

Manufacturing and Process Considerations

Fabricating Taconic PCBs requires precision engineering and controlled manufacturing processes due to the PTFE-based substrate and fine-line routing requirements:

-

Controlled lamination and curing to prevent delamination

-

Precision drilling and via formation for dense multilayer designs

-

Fine-line etching for high-speed trace routing

-

Post-fabrication impedance and insertion loss testing

Attention to these factors ensures that Taconic PCBs deliver consistent high-frequency performance across production volumes.

Application Domains

Taconic PCBs are commonly used in applications requiring high-frequency stability, low loss, and thermal reliability:

-

RF and microwave communication modules

-

5G and mmWave antenna and front-end boards

-

Satellite and aerospace electronics

-

High-speed computing backplanes

-

Radar and defense systems

Engineering Perspective

Taconic PCB materials are not merely substrates—they are performance enablers for high-speed, high-frequency electronic systems. By selecting the appropriate Taconic laminate, designing controlled impedance layouts, and adhering to precise manufacturing processes, engineers can ensure low loss, high signal fidelity, and long-term reliability.

KKPCB provides Taconic PCB solutions with multilayer stackup design support, material selection guidance, and precision manufacturing tailored to RF and high-speed digital applications.