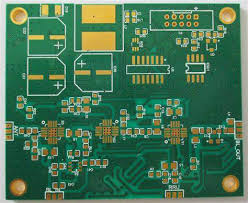

Megtron 6 is a premium high-speed, low-loss PCB laminate developed by Panasonic, designed specifically for next-generation high-frequency and high-data-rate systems. Positioned between standard FR-4 and PTFE-based microwave materials, Megtron 6 delivers exceptionally low transmission loss, stable dielectric performance, and robust thermal reliability—making it a preferred choice in telecom, networking, data-center, computing, and RF applications.

By combining advanced resin chemistry with reinforced glass structures, Megtron 6 offers PTFE-level signal integrity with significantly better manufacturability, cost efficiency, and multilayer process compatibility.

Key Electrical Properties of Megtron 6

1. Ultra-Low Dielectric Dissipation Factor (Df ≈ 0.002)

A material’s dissipation factor indicates its energy loss. With a Df around 0.002, Megtron 6 minimizes dielectric loss—critical for applications operating above 10 GHz or requiring long-distance high-speed channel performance (25G/50G/100G/400G).

Low Df enables:

-

Higher signal fidelity

-

Minimal insertion loss

-

Improved eye-diagram performance

-

Longer trace lengths without repeaters

2. Stable Dielectric Constant (Dk ≈ 3.7)

The Dk of 3.7 ensures predictable transmission line impedance and reduces signal distortion. Its stability over frequency and temperature makes Megtron 6 ideal for:

-

SerDes architectures

-

Differential pairs

-

RF/microwave structures

-

High-speed backplanes

Compared with PTFE, Megtron 6 provides easier processing and tighter Dk tolerance across the panel.

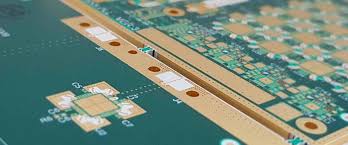

3. Low Transmission Loss

High-speed PCBs must minimize loss from both dielectric and conductor effects. Megtron 6 uses:

-

ultra-smooth copper foils

-

advanced epoxy resin systems

-

optimized glass weave structures

These work together to significantly reduce:

-

insertion loss

-

skin-effect-induced conductor loss

-

skew from glass-weave effects

This is critical for 112G PAM4 networks, 5G transceivers, and HPC systems.

High Thermal Performance and Process Reliability

Megtron 6 is engineered for robust thermal endurance, meeting the growing demands of lead-free soldering, multilayer lamination cycles, and extreme-temperature environments.

Thermal advantages include:

-

high decomposition temperature (Td)

-

strong T260/T288 performance

-

superior CAF resistance

-

reliable through-hole plating (PTH) durability

These factors are essential for PCB stackups exceeding 20–30 layers or high-speed HDI architectures.

Environmental Compliance

Megtron 6 meets:

-

RoHS requirements

-

Halogen-free options

-

strict harmful-substance limitations

This ensures compatibility with global environmental regulations and safe use in industrial, aerospace, and consumer markets.

Applications of Megtron 6 Laminates

Megtron 6 is widely used across industries demanding high-speed digital performance and robust thermal and electrical stability.

1. High-Frequency Measurement & Test Equipment

Accurate readings require stable dielectric behavior. Megtron 6 ensures:

-

minimal signal distortion

-

precise impedance control

Typical use:

Network analyzers, RF meters, precision IC test systems.

2. High-Speed Network Equipment

Ideal for large-scale networking systems, including:

-

5G communication infrastructure

-

routers and switches

-

fiber channel equipment

-

high-speed backplanes

Signal integrity performance remains consistent even at 25–112+ Gbps data rates.

3. High-Performance Computing & Data Centers

For high-density servers and mainframes, Megtron 6 offers:

-

stable high-speed channel performance

-

reduced heat buildup

-

extended system lifetimes

4. IC Testers and ATE Equipment

Automatic test equipment (ATE) requires:

-

unmatched signal integrity

-

strict timing accuracy

-

resistance to thermal cycling

Megtron 6 meets all of these requirements.

Advantages of Megtron 6 Laminates

Excellent Through-Hole Reliability

Megtron 6’s resin/glass structure ensures durable PTH walls through repeated thermal cycles, improving reliability for:

-

multilayer designs

-

mission-critical systems

-

mechanically stressed assemblies

High Efficiency in High-Speed Designs

The laminate’s low loss enables:

-

cleaner eye diagrams

-

reduced jitter

-

longer trace routing distance

-

fewer repeaters or retimers

This improves system-level performance and reduces component costs.

Superior Durability

Megtron 6 resists:

-

mechanical stress

-

chemical exposure

-

environmental cycling

This makes it suitable for industrial, telecom, and defense-grade electronics.

High Thermal & Electrical Conductivity

Improved thermal management helps prevent:

-

overheating

-

delamination

-

performance drift

Electrical performance remains stable even under high-speed switching and RF loads.