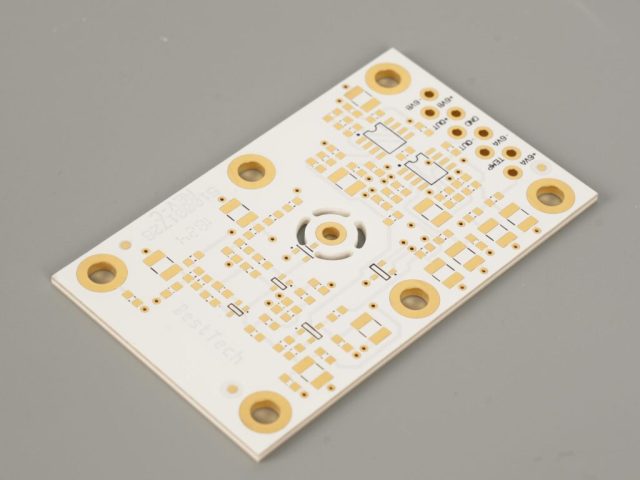

An Aluminum Nitride PCB (AlN PCB) is a ceramic-based circuit substrate engineered for electronic systems that demand exceptional thermal conductivity, electrical insulation, and dimensional stability under high power density and elevated temperature conditions. In power electronics and high-reliability applications, material selection is not a secondary decision—it defines system performance limits.

Material-driven Aluminum Nitride PCB design focuses on leveraging intrinsic AlN properties to achieve stable electrical behavior and efficient heat dissipation where conventional organic PCB materials fail.

Material Properties of Aluminum Nitride PCBs

The defining advantage of an Aluminum Nitride PCB is its high intrinsic thermal conductivity, typically ranging from 140 to 180 W/m·K, significantly higher than alumina-based ceramics. At the same time, AlN maintains excellent electrical insulation and dielectric strength.

Key material characteristics of Aluminum Nitride PCBs include:

-

High thermal conductivity for rapid heat spreading

-

Low dielectric loss and stable dielectric constant

-

High electrical resistivity and breakdown voltage

-

Low coefficient of thermal expansion (CTE) close to silicon

This unique combination makes Aluminum Nitride PCB substrates highly compatible with modern semiconductor devices.

Thermal Stability in High-Power Applications

In high-power electronics, localized heat generation can quickly degrade performance and reliability. Aluminum Nitride PCB substrates enable direct thermal paths from power devices to heat sinks, minimizing thermal resistance.

Thermal advantages of Aluminum Nitride PCB design include:

-

Efficient heat dissipation from IGBTs, MOSFETs, and power ICs

-

Reduced thermal gradients across the PCB

-

Improved junction temperature control

-

Stable performance under continuous high-temperature operation

These benefits are particularly critical in power modules, EV inverters, and industrial motor drives.

Electrical Stability and Insulation Performance

Beyond thermal performance, Aluminum Nitride PCBs provide superior electrical stability in high-voltage and high-current environments. Unlike polymer-based laminates, AlN maintains consistent dielectric behavior across wide temperature ranges.

Electrical benefits include:

-

High dielectric strength for high-voltage isolation

-

Minimal dielectric drift over temperature and time

-

Resistance to partial discharge and electrical aging

-

Stable signal behavior in power control circuits

This makes Aluminum Nitride PCBs suitable for applications where electrical insulation reliability is critical.

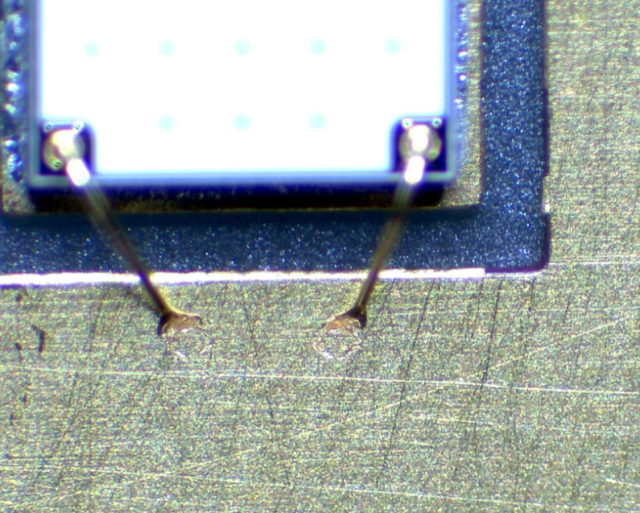

CTE Matching and Mechanical Reliability

A major engineering advantage of Aluminum Nitride PCB substrates is their CTE compatibility with silicon. This reduces thermomechanical stress at the device-to-substrate interface during thermal cycling.

Material-driven mechanical advantages include:

-

Reduced solder joint fatigue

-

Improved reliability of die-attach interfaces

-

Lower risk of cracking under thermal shock

-

Enhanced long-term mechanical stability

CTE matching is a key reason Aluminum Nitride PCBs are widely adopted in advanced power modules.

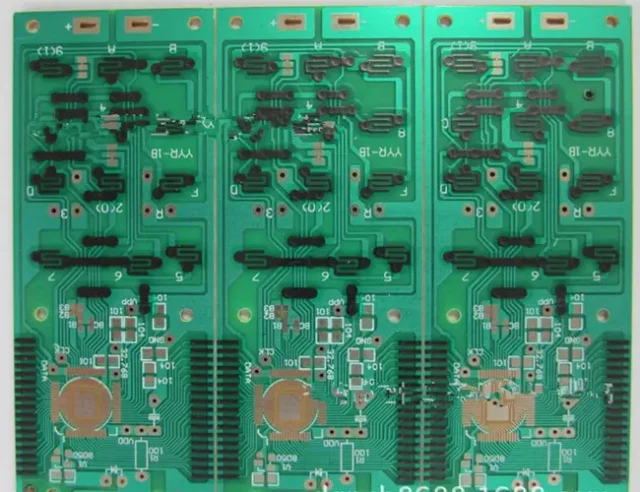

Manufacturing Technologies and Process Control

Aluminum Nitride PCBs are typically fabricated using Direct Bonded Copper (DBC) or Active Metal Brazing (AMB) processes. Each method influences copper adhesion strength, current-carrying capability, and thermal performance.

Critical manufacturing considerations include:

-

Copper thickness selection for current and heat spreading

-

Bonding quality between copper and ceramic substrate

-

Controlled metallization to prevent delamination

-

Precision machining to avoid ceramic cracking

Strict process control is essential to preserve the intrinsic advantages of Aluminum Nitride PCB materials.

Application Domains

Material-driven Aluminum Nitride PCB design is commonly applied in:

-

Power modules for EV and hybrid vehicles

-

SiC and GaN-based power electronics

-

Aerospace and defense power systems

-

Industrial inverters and converters

-

High-power LED and laser drivers

In these applications, Aluminum Nitride PCBs enable higher power density and longer operational life.

Engineering Perspective

An Aluminum Nitride PCB is not merely a substrate choice—it is a strategic material solution that enables thermal and electrical stability in demanding power electronics systems. By aligning material properties, thermal design, and manufacturing processes, engineers can unlock performance levels unattainable with traditional PCB technologies.

KKPCB supports material-driven Aluminum Nitride PCB solutions through disciplined engineering, controlled manufacturing processes, and application-specific design support.