Low Loss Materials: Why They Matter for Modern High-Speed and High-Frequency PCB Design

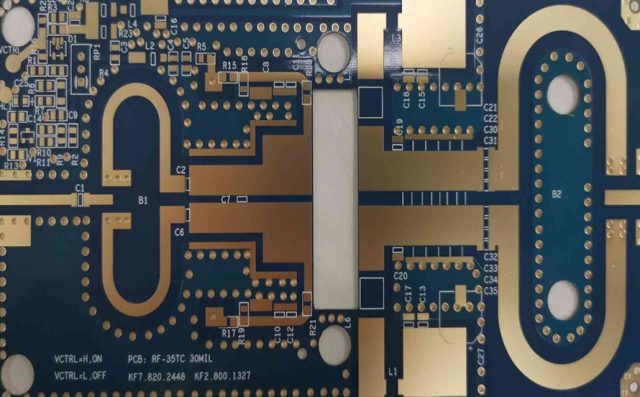

As electronic devices become faster and more compact, engineers are facing new challenges in maintaining clean and stable signals across the PCB. In applications such as 5G communication, data centers, high-speed networking, automotive radar, and advanced computing, signal loss can directly impact system performance and reliability.

This is where low loss materials become essential. By offering low dielectric loss (low Df) and stable dielectric constant (stable Dk), low loss PCB materials help reduce attenuation, improve impedance stability, and maintain signal integrity—especially at high frequencies and high data rates.

In this article, we’ll explain what low loss materials are, their advantages, typical applications, and how to select the right material for your PCB project.

What Are Low Loss Materials in PCB Manufacturing?

Low loss materials refer to PCB laminate and prepreg systems designed to minimize signal loss during transmission. In high-speed and high-frequency circuits, the dielectric material has a major influence on performance.

Compared with standard FR4, low loss materials typically provide:

-

Lower dielectric dissipation factor (Df)

-

More stable dielectric constant (Dk)

-

Better impedance control consistency

-

Improved performance for long trace routing and high-speed interfaces

These materials are widely used for advanced communication and computing applications.

Key Benefits of Low Loss PCB Materials

1. Reduced Signal Attenuation

Signal loss becomes more severe as frequency increases. Low loss materials help reduce attenuation, supporting:

-

Longer transmission distances

-

Cleaner eye diagrams

-

Better high-frequency efficiency

-

Lower insertion loss

This is especially important in high-speed backplanes and RF transmission lines.

2. Improved Signal Integrity

Low loss materials improve overall signal integrity by minimizing:

-

Distortion and jitter

-

Crosstalk and noise sensitivity

-

Phase delay variation

This helps high-speed digital interfaces perform reliably under real operating conditions.

3. Stable Dk for Consistent Impedance

A stable dielectric constant ensures more predictable impedance and timing, which is critical for:

-

Controlled impedance routing

-

Differential pair stability

-

High-speed interconnect design

Even small variations in Dk can cause measurable impedance mismatch and reflection issues.

4. Better Performance for High-Speed Digital and RF

Low loss materials are not only for RF. They are also widely used in high-speed digital designs where bandwidth and timing are critical, such as:

-

PCIe / high-speed serial links

-

High-speed networking equipment

-

AI computing and data center systems

Typical Applications of Low Loss Materials

High-Speed Networking and Data Centers

Low loss materials are widely used in:

-

Switches and routers

-

High-speed backplanes

-

Server motherboards and accelerator boards

They support high data rates with lower loss and better reliability.

5G Communication Systems

Low loss materials help improve performance in:

-

5G base stations

-

RF modules and antenna feed networks

-

High-frequency communication hardware

They support stable RF performance and reduced insertion loss.

Automotive Radar and ADAS

For automotive radar systems, low loss materials help ensure:

-

Stable high-frequency signal performance

-

Reliable operation under temperature cycling

-

Consistent manufacturing quality

High-Frequency RF and Microwave Modules

Low loss laminates are ideal for:

-

RF front-end modules

-

Filters, couplers, and amplifiers

-

Microwave communication systems

Low Loss Materials vs Standard FR4

FR4 is cost-effective and widely used, but it may not meet high-speed or high-frequency requirements.

| Feature | Standard FR4 | Low Loss Materials |

|---|---|---|

| Dielectric Loss (Df) | Higher | Lower |

| Signal Attenuation | Higher | Lower |

| Dk Stability | Moderate | Better |

| High-Speed Performance | Limited | Excellent |

| Typical Use | General electronics | High-speed / RF systems |

For high-performance applications, low loss materials are often the best choice to ensure stable signal integrity.

How to Choose the Right Low Loss Material

To select the right low loss PCB material, it’s important to consider:

-

Signal frequency and data rate requirements

-

Target impedance and stack-up design

-

Trace length and routing density

-

Thermal reliability and operating environment

-

PCB fabrication capability and lead time

-

Total cost vs performance targets

A professional PCB manufacturer can help recommend suitable low loss materials based on your design requirements and application needs.

Conclusion

Low loss materials are essential for modern electronics requiring high-speed performance, low attenuation, stable impedance, and strong signal integrity. They are widely used in data centers, high-speed networking, 5G systems, automotive radar, and advanced RF modules, helping designers achieve consistent and reliable performance beyond standard FR4.

If your project involves high-speed digital signals or high-frequency RF circuits, selecting the right low loss PCB material is a key step toward product success.