Engineering Context: Why High TG PCB Is Critical in Modern Electronics

As electronic systems continue to push toward higher power density, faster signal speeds, and harsher operating environments, conventional PCB materials increasingly become a reliability bottleneck. Excessive heat, repeated thermal cycling, and dense component placement place enormous stress on standard laminates, often leading to warpage, delamination, via cracking, and signal degradation.

High TG PCB materials—defined by a glass transition temperature (TG) typically above 170 °C—are engineered to maintain mechanical stability, dielectric consistency, and electrical performance under elevated temperatures. For applications such as automotive electronics, industrial automation, high-speed networking, power electronics, and communication infrastructure, High TG PCB is no longer optional; it is a foundational requirement for long-term reliability.

Understanding TG and Its Impact on PCB Performance

Glass Transition Temperature (TG) represents the point at which a PCB laminate transitions from a rigid, glass-like state to a softer, rubber-like state. Below TG, the material exhibits stable mechanical and dielectric behavior. Above TG, thermal expansion accelerates rapidly, increasing stress on copper traces, vias, and solder joints.

High TG PCB materials delay this transition, allowing the PCB to operate safely at higher temperatures with:

-

Reduced Z-axis expansion

-

Improved via reliability

-

Lower risk of delamination

-

Stable dielectric properties under thermal load

This thermal resilience directly translates into improved electrical stability, especially for high-speed and high-frequency circuits.

Core Engineering Challenges Addressed by High TG PCB

Modern electronic systems face several thermal and reliability challenges that High TG PCB materials are designed to solve:

| Engineering Challenge | Root Cause | Impact Without High TG PCB |

|---|---|---|

| PCB warpage | Excessive thermal expansion | Assembly defects, BGA failure |

| Via cracking | Z-axis expansion during reflow | Intermittent connections |

| Delamination | Resin softening above TG | Long-term reliability loss |

| Signal instability | Dielectric drift with temperature | Impedance mismatch, eye closure |

| Solder joint fatigue | Repeated thermal cycling | Early field failure |

By using High TG PCB materials, these risks are significantly reduced, enabling stable operation across wide temperature ranges.

Material Characteristics of High TG PCB

High TG PCB laminates are typically formulated with advanced epoxy or hybrid resin systems optimized for thermal endurance. Key material parameters include:

| Parameter | Typical Value | Engineering Benefit |

|---|---|---|

| TG | 170–210 °C | Maintains rigidity during reflow and operation |

| Z-axis CTE | < 55 ppm/°C | Reduces via stress |

| Decomposition Temperature (Td) | > 350 °C | Prevents resin breakdown |

| Dielectric Stability | Minimal drift | Consistent impedance control |

| CAF Resistance | High | Improved long-term reliability |

These properties make High TG PCB suitable for multi-layer designs, HDI structures, and complex stackups with fine-pitch components.

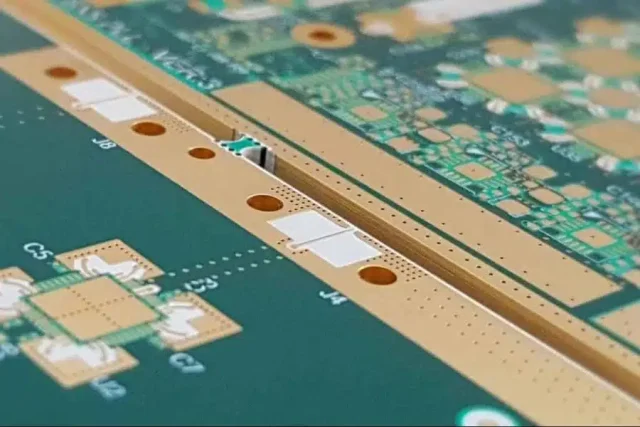

High TG PCB in High-Speed and High-Power Designs

In high-speed digital systems, temperature-induced dielectric changes can directly affect signal integrity. High TG PCB materials offer improved dielectric stability, helping maintain controlled impedance for differential pairs and high-speed serial links.

For power electronics and high-current designs, High TG PCB provides better mechanical endurance near hot components such as MOSFETs, IGBTs, and power regulators. Combined with thicker copper or thermal vias, High TG PCB enables robust thermal management without sacrificing reliability.

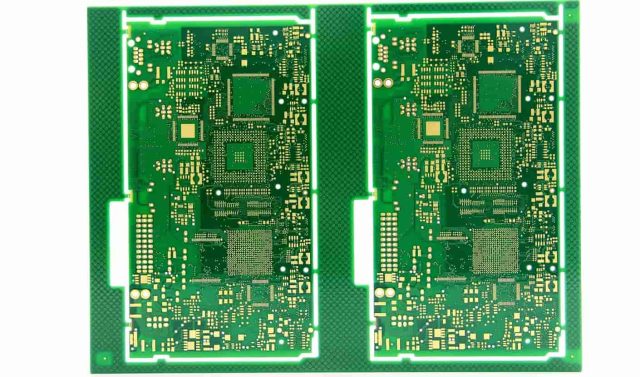

KKPCB Engineering Approach to High TG PCB Manufacturing

At KKPCB, High TG PCB production is treated as an engineering-controlled process rather than a commodity service. Our approach includes:

-

Precise lamination profile control to avoid resin over-curing

-

Z-axis expansion modeling for via reliability optimization

-

Controlled impedance stackup design based on operating temperature

-

Thermal stress simulation before fabrication

-

Strict reflow compatibility verification

By integrating material science, process control, and design-for-reliability principles, KKPCB ensures that every High TG PCB meets both electrical and mechanical performance targets.

Typical Application Areas for High TG PCB

High TG PCB materials are widely used in applications where thermal stress and reliability are critical:

-

Automotive ECUs and ADAS systems

-

Industrial automation controllers

-

High-speed networking and data center hardware

-

Power supply and inverter systems

-

Communication infrastructure and base stations

-

Aerospace and defense electronics

In these environments, High TG PCB significantly extends product lifespan and reduces failure rates.

Engineering Summary

High TG PCB materials provide a robust foundation for modern high-performance electronics by delivering superior thermal stability, mechanical reliability, and consistent electrical behavior. As systems operate at higher temperatures and power densities, High TG PCB becomes essential for maintaining signal integrity and structural durability.

With advanced material selection, precision manufacturing, and engineering-driven process control, KKPCB delivers High TG PCB solutions that support demanding applications across automotive, industrial, communication, and high-speed electronics sectors.