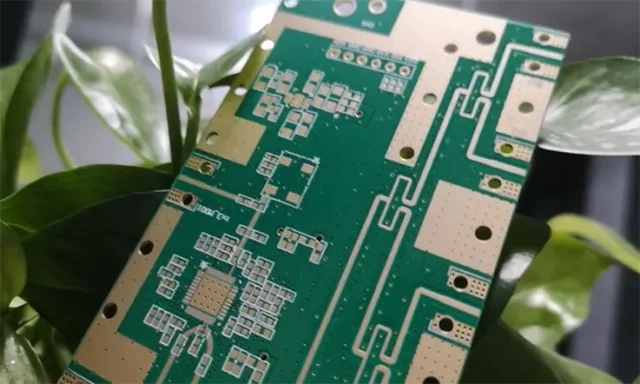

Hybrid PCB materials combine two or more substrate types—such as high-speed laminates, low-loss materials, BT epoxy, and ceramics—to create boards optimized for electrical performance, thermal management, and mechanical stability. Unlike single-material PCBs, hybrid designs allow engineers to tailor material properties to different areas of the circuit, achieving performance levels unattainable with conventional laminates.

Why Hybrid PCB Materials Are Used

Modern electronic systems increasingly integrate high-speed digital, RF, and power circuits onto a single PCB. Each functional block has unique material requirements:

-

High-speed signal traces require low-loss, controlled-Dk laminates

-

Power sections demand high Tg and high thermal conductivity substrates

-

Mixed-signal zones need dielectric stability and impedance consistency

Hybrid PCB materials allow designers to allocate the right material to the right function, balancing electrical, thermal, and mechanical constraints across a single board.

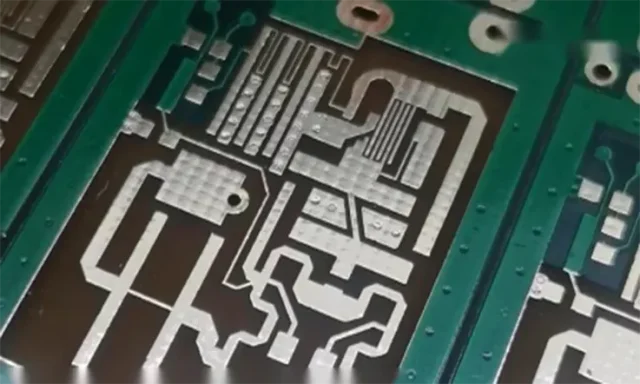

Electrical and Signal Integrity Benefits

By combining materials with optimized dielectric constants (Dk) and low dissipation factors (Df), hybrid PCBs achieve:

-

Controlled impedance for high-speed data channels

-

Reduced insertion loss and phase distortion in RF and microwave circuits

-

Minimized crosstalk and signal skew in dense interconnects

-

Predictable high-frequency performance across the board

This multi-material approach ensures signal integrity is maintained even in highly integrated, multi-GHz designs.

Thermal Management Advantages

Hybrid PCB designs can incorporate high-TG or ceramic layers in high-power zones, while maintaining flexible low-loss laminates for RF or digital sections. Benefits include:

-

Improved heat dissipation in power-critical areas

-

Reduced thermal stress on sensitive components

-

Balanced expansion coefficients to minimize warpage

-

Enhanced reliability under repeated thermal cycling

Thermal modeling can guide material placement, ensuring both electrical and thermal targets are met.

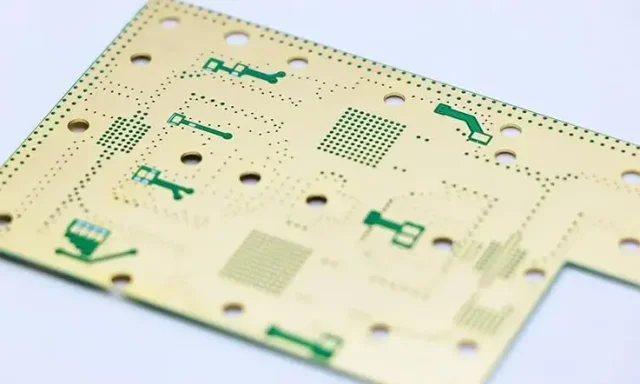

Mechanical and Manufacturing Considerations

Hybrid PCB designs introduce stackup complexity. Engineers must carefully consider:

-

Material compatibility in lamination and curing processes

-

CTE matching to avoid delamination or via cracking

-

Layer registration and thickness control for multilayer stackups

-

Fabrication tolerances in mixed-material zones

With proper process discipline, hybrid PCB manufacturing achieves high yield, precise impedance control, and long-term reliability.

Typical Applications

Hybrid PCB materials are widely used in:

-

High-speed networking and data center boards

-

5G RF front-end modules

-

Aerospace and defense electronics

-

Power electronics with integrated control circuits

-

Mixed-signal systems combining analog, digital, and RF domains

In these applications, hybrid PCBs provide a balanced solution that maximizes performance while minimizing thermal and electrical compromises.

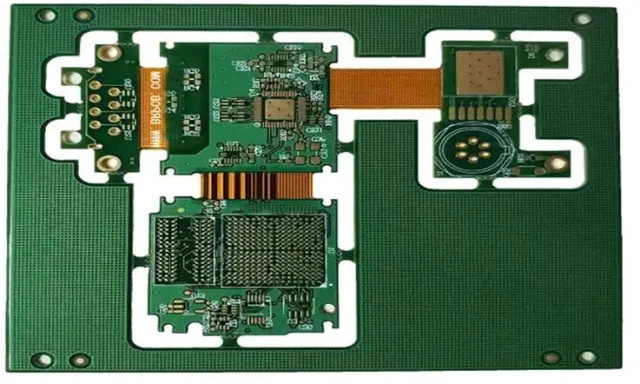

Engineering Perspective

Hybrid PCB materials should be considered a system-level enabler, not merely a combination of laminates. By selecting the right materials for each function and carefully engineering the stackup, designers achieve:

-

Optimized signal integrity

-

Thermal stability in power-dense areas

-

Mechanical reliability across the board

-

Consistent manufacturing performance

KKPCB supports hybrid PCB projects through material selection guidance, multi-material stackup engineering, and advanced manufacturing control, ensuring predictable performance for complex, high-performance electronic systems.