A High Reliability PCB is a printed circuit board engineered to maintain consistent electrical and mechanical performance over extended service life, even under harsh environmental and operational conditions. Unlike standard PCBs, high reliability PCBs are designed with enhanced materials, robust structures, and stringent manufacturing controls to meet the demands of mission-critical applications.

As electronics are increasingly deployed in automotive systems, industrial equipment, communication infrastructure, medical devices, and semiconductor testing, reliability is no longer optional—it is essential. High reliability PCB technology ensures long-term stability, safety, and performance where failure is unacceptable.

Key Characteristics of High Reliability PCBs

1. Advanced High-Reliability Materials

High reliability PCBs use carefully selected materials with excellent thermal stability, mechanical strength, and electrical consistency, such as:

-

High-Tg and low-CTE laminates

-

Low-loss and stable dielectric materials

-

High-quality copper foils for improved fatigue resistance

These materials reduce risks associated with thermal expansion, delamination, and signal degradation.

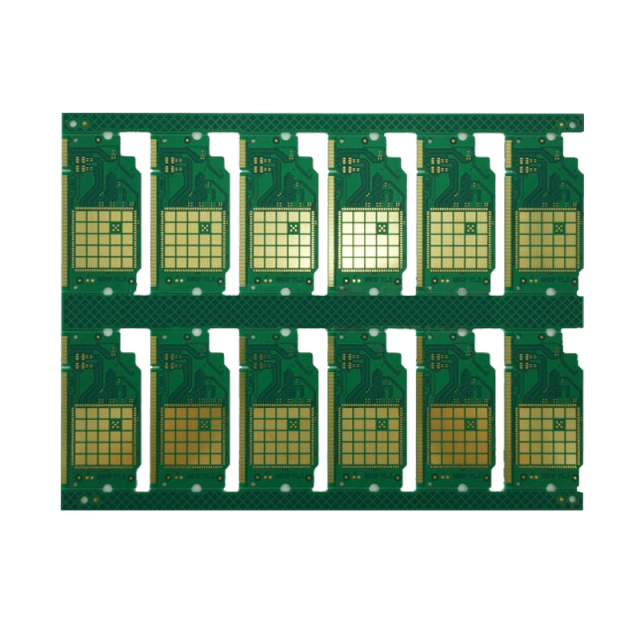

2. Robust Multilayer and Via Structures

To enhance durability, high reliability PCBs often feature:

-

Multilayer stackups with balanced copper distribution

-

Blind and buried vias for improved structural integrity

-

Microvia and via-in-pad designs with reliable filling and plating

These structures improve signal integrity and mechanical robustness under thermal cycling and vibration.

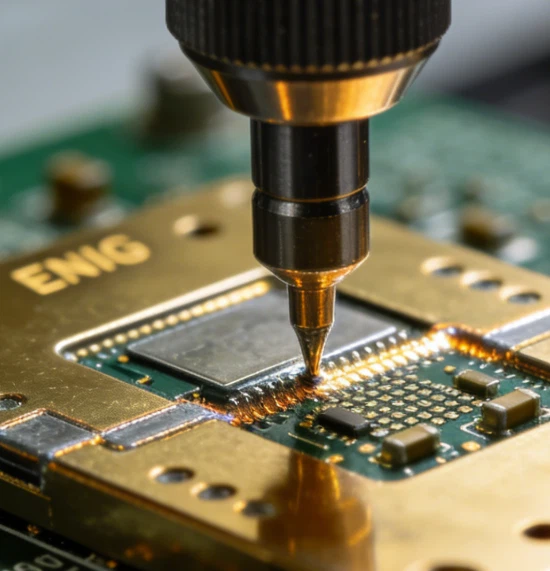

3. Strict Process Control and Manufacturing Precision

High reliability PCB manufacturing requires tight control of every step, including:

-

Precise lamination and layer alignment

-

Controlled drilling, plating, and via reliability

-

Consistent impedance control and copper thickness

This ensures repeatable quality from prototype through mass production.

4. Enhanced Thermal and Mechanical Performance

High reliability PCBs are designed to withstand:

-

Wide operating temperature ranges

-

Continuous high-current or high-power operation

-

Mechanical shock and vibration

Optimized thermal management and structural reinforcement help extend product lifetime.

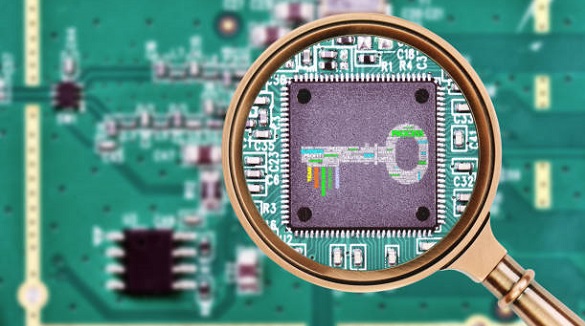

5. Comprehensive Testing and Quality Assurance

High reliability PCBs undergo extensive testing, such as:

-

Electrical testing and impedance verification

-

Thermal cycling and reliability stress testing

-

AOI, X-ray inspection, and microsection analysis

These tests validate long-term performance and manufacturing consistency.

Applications of High Reliability PCBs

High reliability PCBs are essential in industries where system failure can lead to safety risks, downtime, or high costs:

-

Automotive electronics, EV systems, ADAS, and radar modules

-

Industrial automation and control systems

-

Telecommunication and network infrastructure

-

Medical devices and diagnostic equipment

-

Aerospace and defense electronics

-

Semiconductor IC testing, ATE, load boards, and probe cards

Design and Manufacturing Considerations

Designing a high reliability PCB requires close collaboration between design engineers and manufacturers, focusing on:

-

Stackup optimization and material selection

-

Via structure reliability and current carrying capability

-

Controlled impedance and EMI suppression

-

Thermal management and mechanical reinforcement

Manufacturing partners must demonstrate proven experience, stable processes, and rigorous quality systems.

Conclusion

A High Reliability PCB is the cornerstone of mission-critical electronic systems, providing long-term stability, safety, and consistent performance in demanding environments. Through advanced materials, robust structures, precise manufacturing, and strict quality control, high reliability PCBs support the most challenging applications across automotive, industrial, communication, medical, and semiconductor sectors.

Choosing an experienced high reliability PCB manufacturer is a decisive factor in achieving product success and long-term operational confidence.