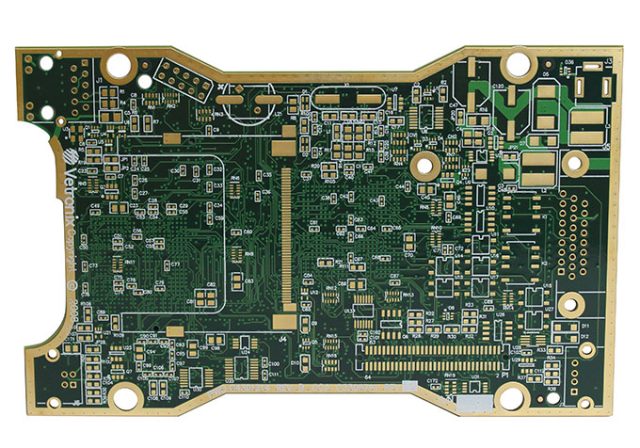

What Is a High Reliability PCB?

A High Reliability PCB is a printed circuit board designed and manufactured to perform consistently under extreme environmental, electrical, and mechanical conditions. These PCBs are engineered for long service life, stable electrical performance, and minimal failure risk.

High reliability PCBs are essential for applications where system failure is not acceptable.

Key Characteristics of High Reliability PCB

A true high reliability PCB must demonstrate:

-

Long-term electrical stability

-

Resistance to thermal cycling

-

High mechanical strength

-

Moisture and corrosion resistance

-

Excellent solder joint reliability

-

Strict impedance and signal integrity control

Reliability is achieved through both material selection and precision manufacturing control.

Materials Used in High Reliability PCB

Material selection plays a critical role in high reliability PCB performance. Common options include:

-

High TG FR-4 materials

-

Low loss high frequency laminates

-

Polyimide materials for high temperature environments

-

Rogers and other advanced RF materials

-

Heavy copper constructions for power applications

Proper material selection ensures durability in harsh operating conditions.

Manufacturing Standards and Quality Control

High reliability PCB manufacturing follows strict international standards, including:

-

IPC Class 3 requirements

-

Automotive IATF 16949 standards

-

ISO 9001 quality systems

-

AOI, X-ray inspection, and electrical testing

-

Microsection analysis and reliability validation

Comprehensive inspection procedures ensure defect-free production.

Design Considerations for High Reliability PCB

To achieve true reliability, design must consider:

-

Proper layer stackup design

-

Controlled impedance routing

-

Thermal management solutions

-

Via structure optimization (blind, buried, filled vias)

-

Redundant grounding and power distribution

Early DFM review helps prevent potential long-term reliability risks.

Applications of High Reliability PCB

High reliability PCBs are widely used in:

-

Automotive electronics and ADAS systems

-

Aerospace and satellite communication

-

Medical diagnostic equipment

-

Industrial automation systems

-

Energy and power conversion systems

-

Defense and mission-critical electronics

These industries demand zero compromise in performance and durability.

Environmental and Stress Resistance

High reliability PCB solutions are designed to withstand:

-

High temperature environments

-

Rapid thermal cycling

-

Vibration and mechanical shock

-

High humidity exposure

-

Chemical contamination

Environmental testing verifies long-term operational stability.

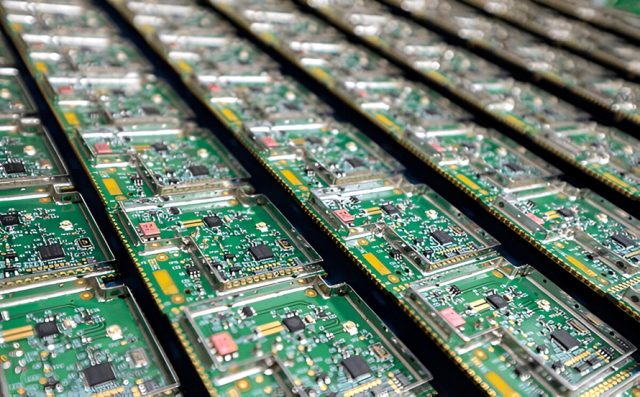

High Reliability PCB Assembly

Reliability does not stop at fabrication. High reliability PCB assembly includes:

-

Controlled soldering profiles

-

Traceable component sourcing

-

Strict ESD protection

-

Functional and burn-in testing

-

Full traceability documentation

Assembly quality directly impacts overall system reliability.

Why Choose a Professional High Reliability PCB Manufacturer

An experienced high reliability PCB manufacturer provides:

-

Deep expertise in mission-critical applications

-

Advanced material processing capabilities

-

Strict IPC Class 3 manufacturing control

-

Full traceability and quality documentation

-

Prototype to mass production support

Choosing the right partner ensures consistent performance and long-term stability.