What Is a High Reliability PCB?

A High Reliability PCB is engineered to deliver stable electrical performance, mechanical durability, and long-term consistency under extreme operating conditions. Unlike standard commercial PCBs, high reliability PCBs are designed to withstand high temperature, thermal cycling, vibration, humidity, and continuous operation without performance degradation.

These boards are widely used in automotive electronics, aerospace systems, industrial automation, power control, medical devices, and semiconductor testing equipment, where failure is not an option.

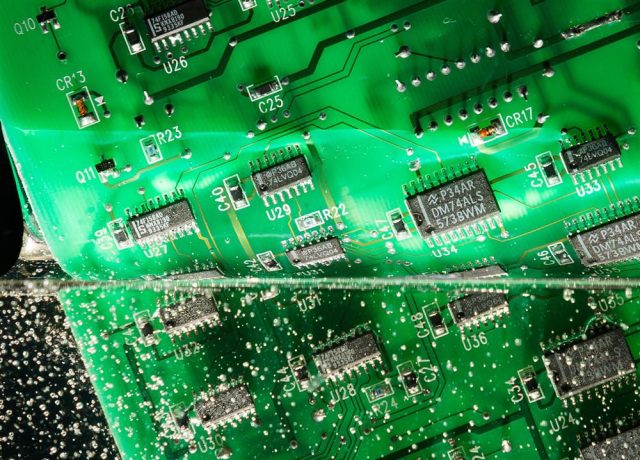

Key Characteristics of High Reliability PCBs

To meet demanding application requirements, High Reliability PCB manufacturing focuses on strict material control, precision processes, and enhanced inspection standards:

-

Controlled impedance and signal integrity

-

Low-loss and high-Tg laminate materials

-

Robust via structures (filled, capped, blind & buried vias)

-

Enhanced copper adhesion and plating thickness

-

Tight tolerance for layer alignment and trace geometry

-

Superior thermal management capability

Every design detail is optimized to ensure electrical stability and mechanical robustness throughout the product lifecycle.

Materials Used in High Reliability PCB Fabrication

Material selection is critical for High Reliability PCB performance. Common materials include:

-

High-Tg FR-4 for industrial-grade electronics

-

Rogers, PTFE, and hybrid laminates for RF and high-speed systems

-

Polyimide for high-temperature and aerospace applications

-

Low CTE materials for high layer count and fine-pitch designs

These materials help minimize thermal stress, signal loss, and structural deformation during operation.

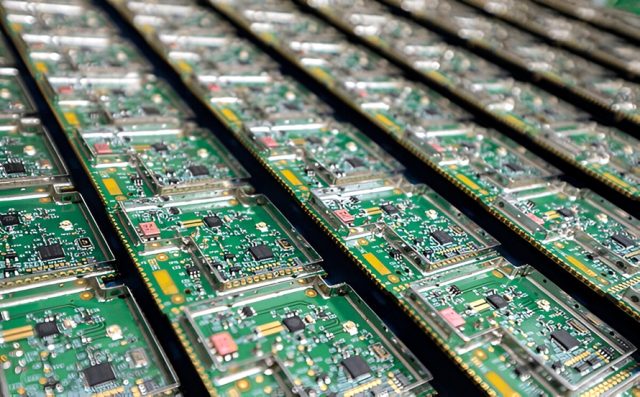

Applications of High Reliability PCBs

High Reliability PCBs are essential in environments where downtime or failure leads to significant risk or cost:

-

Automotive ECUs, ADAS, and power modules

-

Aerospace and defense electronics

-

Industrial control and automation systems

-

Semiconductor ATE, load boards, and test interfaces

-

Medical monitoring and diagnostic equipment

-

Power supply and energy management systems

Each application demands consistent electrical performance and extended service life.

Manufacturing and Quality Control Standards

Producing a High Reliability PCB requires strict process control and comprehensive inspection:

-

IPC Class 2 / Class 3 compliance

-

Automated Optical Inspection (AOI)

-

X-ray inspection for via and BGA structures

-

Electrical testing and impedance verification

-

Thermal stress and reliability validation

These measures ensure every PCB meets the reliability expectations of mission-critical applications.

Why Choose a High Reliability PCB Partner?

Choosing the right High Reliability PCB manufacturer ensures:

-

Stable long-term supply

-

Engineering support from prototype to mass production

-

Consistent quality across batches

-

Reduced field failure and maintenance cost

A reliable PCB partner helps protect your product performance and brand reputation.