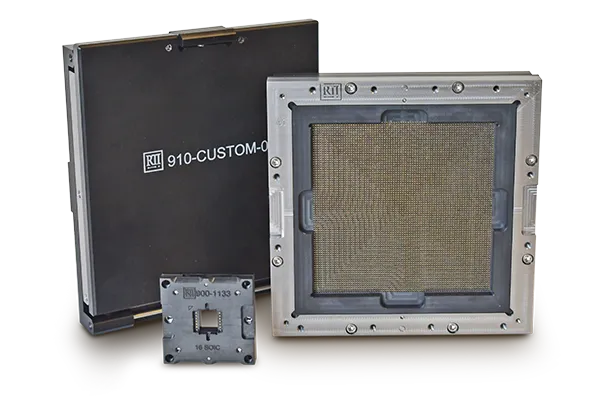

A High Pin Count IC Test Board is a specialized semiconductor test PCB designed to support ICs with hundreds or even thousands of I/O pins. These boards are widely used in Automated Test Equipment (ATE) systems to validate performance, functionality, and reliability of advanced integrated circuits during engineering validation and mass production.

As IC packaging evolves toward higher integration, smaller pitch, and higher-speed interfaces, high pin count IC test boards have become essential to ensure accurate signal transmission, stable power delivery, and consistent test repeatability.

Key Challenges of High Pin Count IC Test Boards

1. Dense Routing and Fine Pitch Design

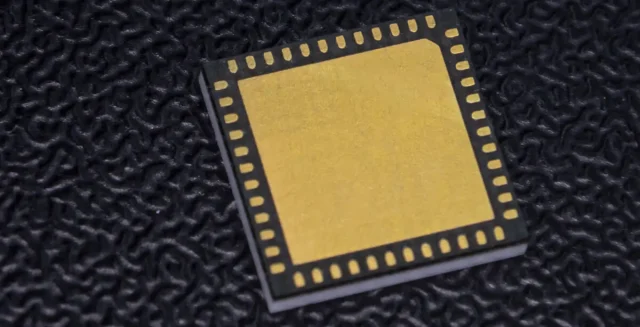

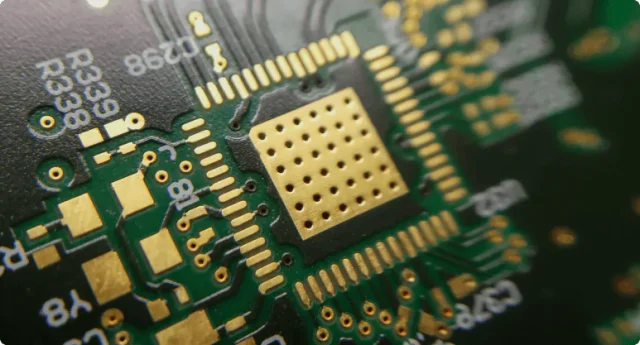

High pin count ICs such as BGAs, LGAs, and advanced packages require fine-line trace routing and microvia structures. HDI PCB technology is essential to efficiently fan out dense pin arrays without compromising signal quality.

2. Signal Integrity at High Speed

Modern ICs operate at increasingly higher data rates. High pin count IC test boards must implement controlled impedance, length matching, and crosstalk control to maintain clean signal transmission across all channels.

3. Power Integrity and Thermal Stability

Supplying stable power to a large number of I/O pins requires optimized power and ground plane design. Proper thermal management ensures consistent electrical performance during long test cycles.

4. Mechanical Precision and Reliability

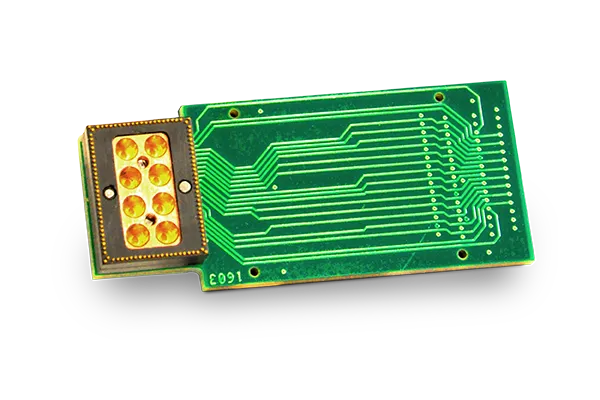

Accurate pad positioning and PCB flatness are critical for maintaining reliable contact with test sockets, probe pins, or connectors, especially during repeated insertion and removal cycles.

Design Features of High Pin Count IC Test Boards

A well-designed high pin count IC test board typically includes:

-

HDI multilayer PCB stackups

-

Microvias, blind vias, and buried vias

-

Controlled impedance signal layers

-

Low-loss and high-Tg PCB materials

-

Optimized power distribution networks (PDN)

These features ensure electrical stability, mechanical durability, and long-term test accuracy.

Applications of High Pin Count IC Test Boards

High pin count IC test boards are widely used in:

-

Logic and processor IC testing

-

Memory and storage IC validation

-

RF and mixed-signal IC testing

-

Automotive electronics and ADAS IC testing

-

High-performance computing (HPC) semiconductor testing

Each application places strict requirements on signal integrity, repeatability, and reliability.

Manufacturing Capabilities Required

Manufacturing high pin count IC test boards requires advanced PCB fabrication expertise, including:

-

Ultra-fine line and space control

-

Precision drilling and via filling

-

Impedance control and verification

-

Tight tolerance multilayer lamination

-

Prototype, small batch, and volume production support

High manufacturing consistency directly impacts test accuracy and board lifespan.

Why High Pin Count IC Test Boards Matter

Poorly designed or manufactured high pin count test boards can cause signal degradation, contact instability, and false test failures, leading to increased cost and reduced yield. High-quality boards provide:

-

Reliable electrical contact across all pins

-

Stable high-speed signal transmission

-

Reduced socket and probe wear

-

Improved ATE throughput and test efficiency

Conclusion

The High Pin Count IC Test Board is a critical foundation for modern semiconductor and ATE testing. By combining HDI PCB technology, controlled impedance design, precise mechanical alignment, and advanced manufacturing, these boards enable accurate, repeatable, and high-speed IC testing.

Choosing an experienced high pin count IC test board manufacturer helps ensure long-term reliability, higher yield, and successful testing of today’s most advanced semiconductor devices.